Clamping device for a device for machining workpiece

A technology for processing workpieces and tools, which is applied in the direction of manufacturing tools, metal processing equipment, tool holder accessories, etc., and can solve the problem of insufficient support and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

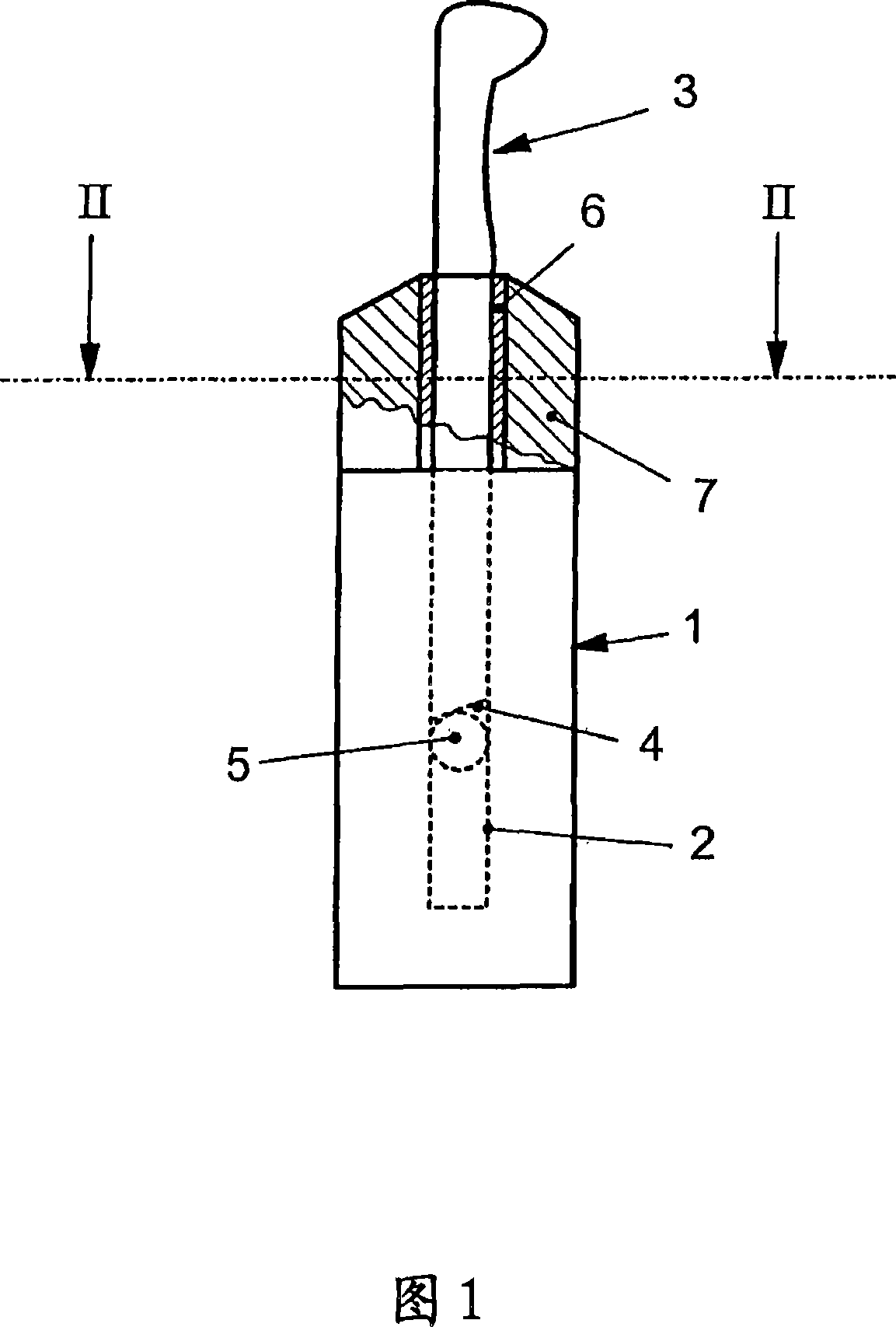

[0021] The device according to the invention for machining workpieces which are not shown in detail has a carrier 1 with a shaft bore 2 indicated by dashed lines. A tool 3 is inserted into the shaft hole 2 and has a bevel 4 at the end of the tool 3 in the shaft hole 2 . Said ramp 4 interacts with a rotation protection mechanism, here a cross-section pin 5 , as described in detail in DE 198 00 424 A1.

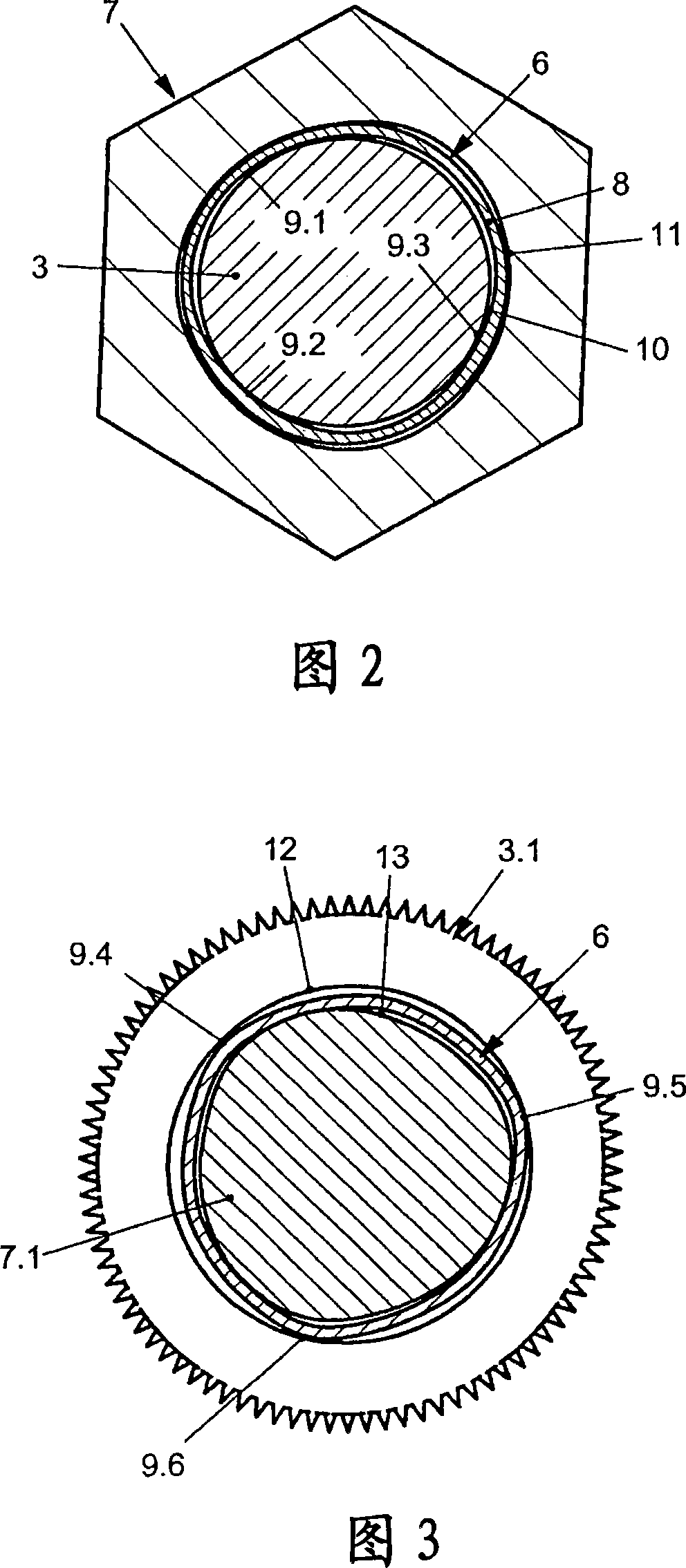

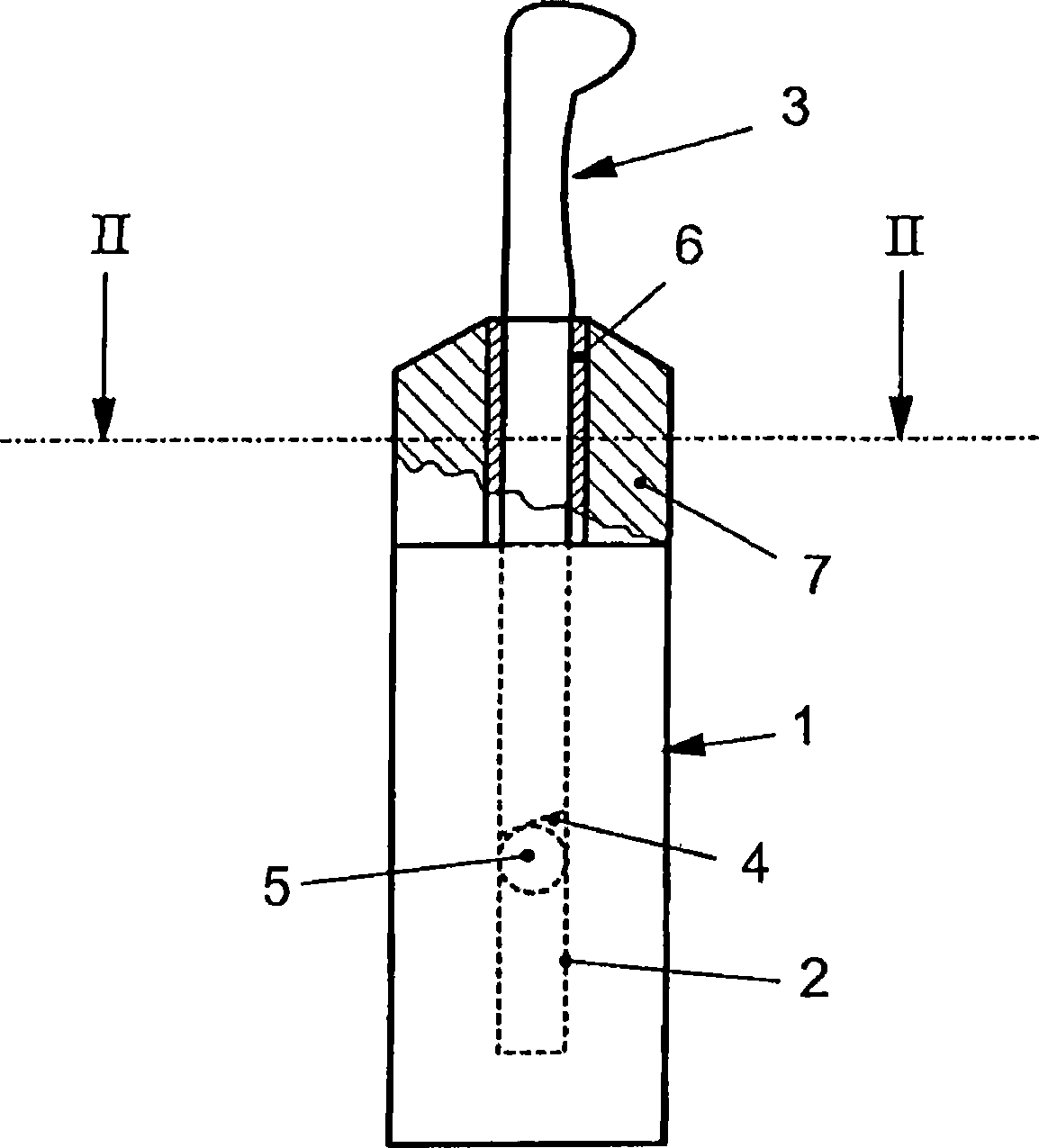

[0022] Before the tool 3 enters the shaft hole 2 it passes through a sleeve 6 surrounded by a rotating element 7 . Such as figure 2 As shown, the rotating element 7 is designed to be hexagonal.

[0023] According to the present invention and as figure 2 As shown in , the sleeve 6 has a non-circular design of the cover 8 . In the present embodiment, it is in contact with the cylindrical tool 3 at three locations 9.1, 9.2 and 9.3, while its inner face 10 has a very small section of rising or falling with the tool 3 in the region between them. Spacing (eg 3 / 100mm).

[0024]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com