Improved external mix air atomizing spray nozzle assembly

A spray nozzle and component technology, applied in the field of "external mixing" air atomizing spray nozzle components, can solve problems such as pressure loss, burr, damage to spray nozzle pressure loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

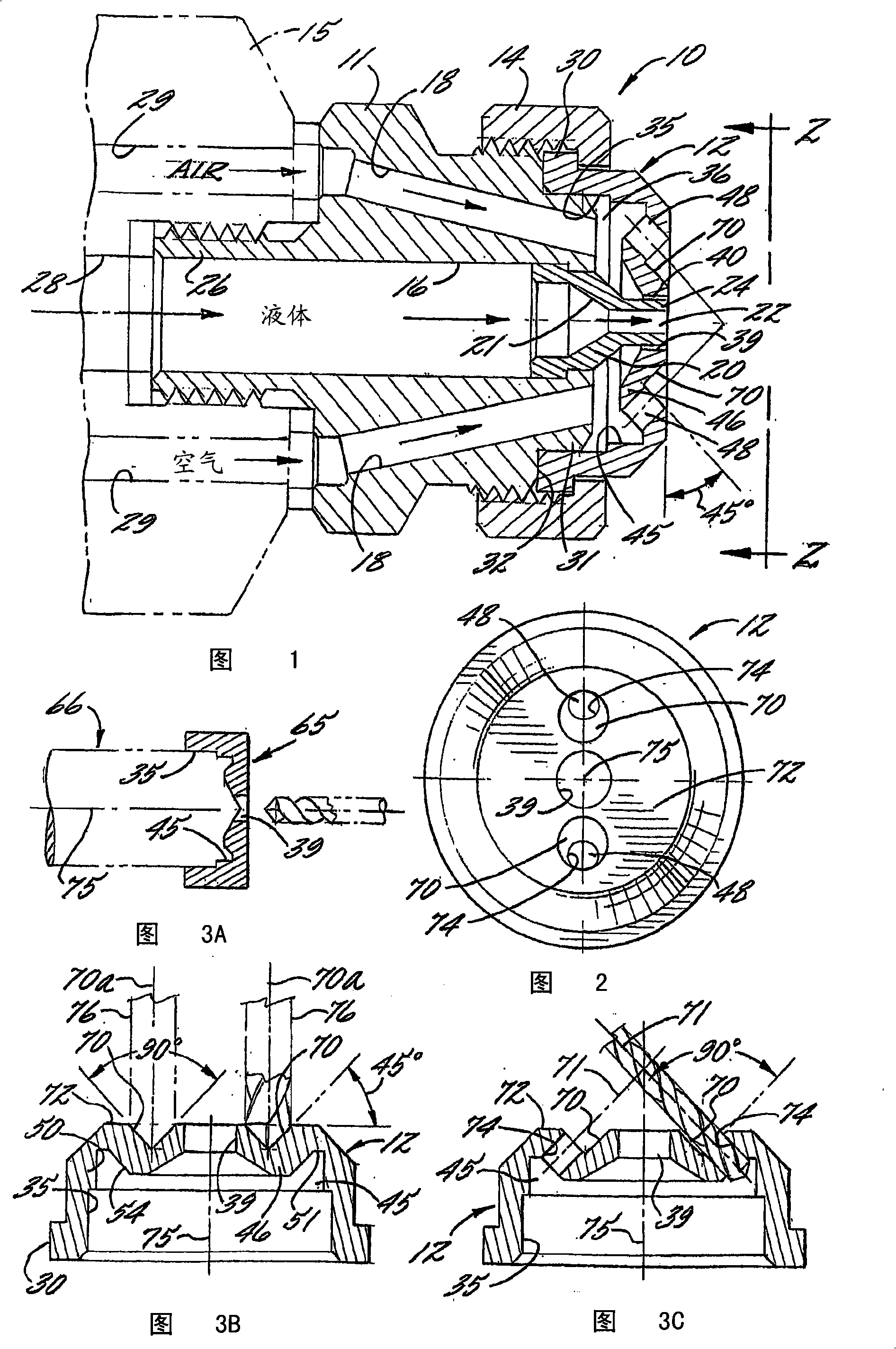

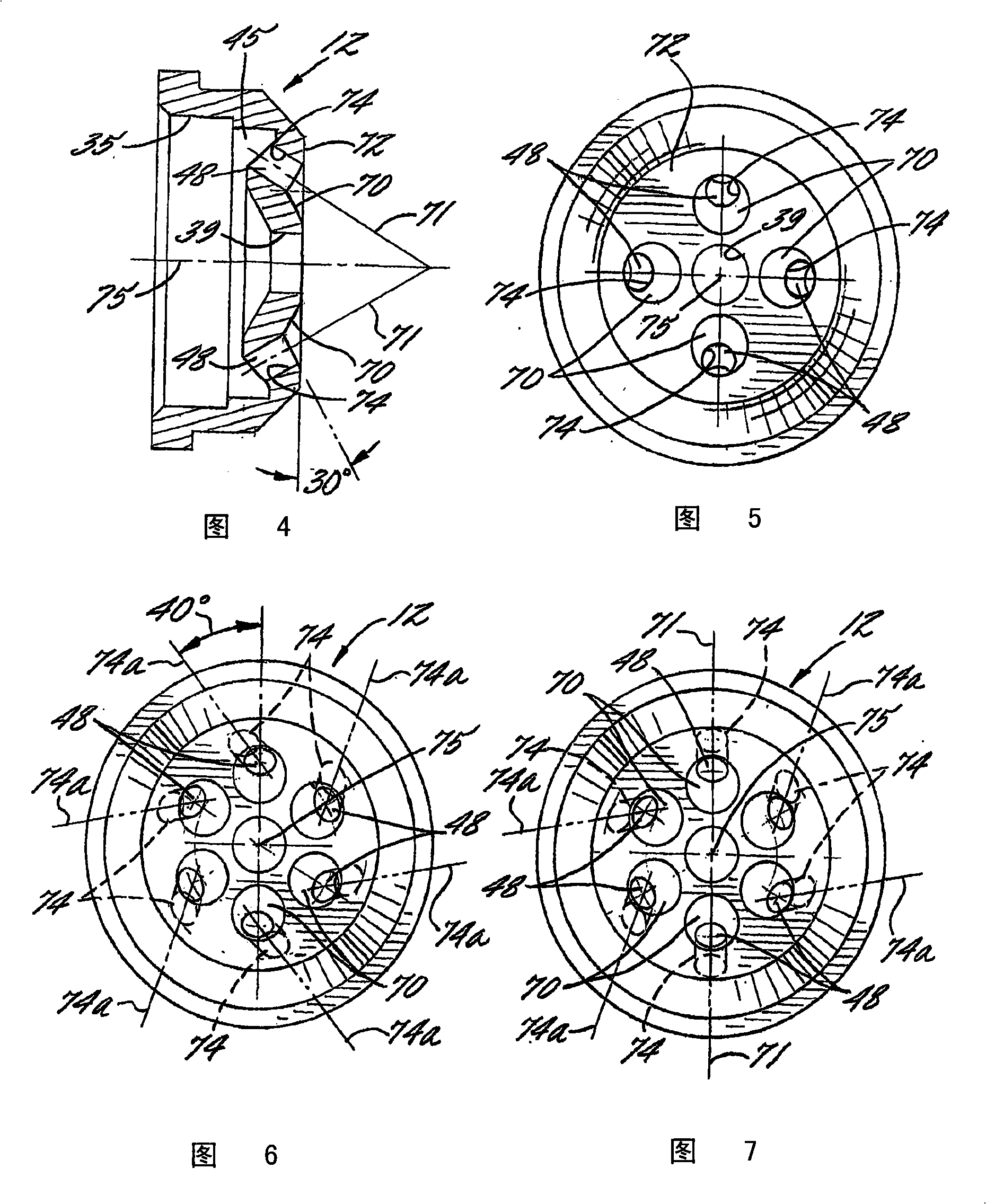

[0018] Referring now to the drawings, there is shown an illustrative spray nozzle assembly 10 embodying the present invention. In this example, the spray nozzle assembly 10 includes: a nozzle body 11; an air cap 12 mounted downstream into the nozzle body 11; and a retaining ring 14 for releasably securing the air cap 12 in the mounted position. The illustrated spray nozzle assembly 10 is mounted on a base or manifold portion 15 through which pressurized liquid and air are fed from a suitable source.

[0019] The illustrated nozzle body 11 has formed therein a central liquid passage 16 and a plurality of pressurized air or gas passages 18 spaced circumferentially from one another around the liquid passage 16 . In this example, the liquid passage 16 communicates with a liquid discharge spray tip 20 fixed at the downstream end of the nozzle body 11 in a direction extending forward with respect to the nozzle body 11 . Liquid spray tip 20 defines a tapered inlet chamber 21 that co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com