Glass curtain wall overlapping joint

A glass curtain wall and barge joint technology, applied in walls, building components, buildings, etc., can solve the problems of complex barge joint structure, production or installation errors, limited swing angle, etc., and achieve the effect of saving material costs and production costs

Inactive Publication Date: 2008-10-22

SHENZHEN GUIHANG IND

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The existing glass curtain wall barge joint includes a fixing seat and a connecting rod. One end of the connecting rod is a universal ball head, and the universal ball head is arranged in the inner cavity of the fixing seat, and then a restraining piece is set at the mouth of the inner cavity, so that The universal ball head is fixed in the inner cavity for a certain rotation. This kind of constraint is loosened due to the long-term vibration of the barge joint. In severe cases, the universal ball head is detached and accidents occur. Difficulty in installation and debugging

The existing barge joints have complex structures, and most of them adopt casting technology, which greatly increases the cost of materials and production costs

And because of its poor cushioning performance, the service life is also affected

In addition, considering the structural limitations, the swing angle of the current universal ball head in the inner cavity is limited, resulting in a small angle deflection and increasing the difficulty of installing the barge joint

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

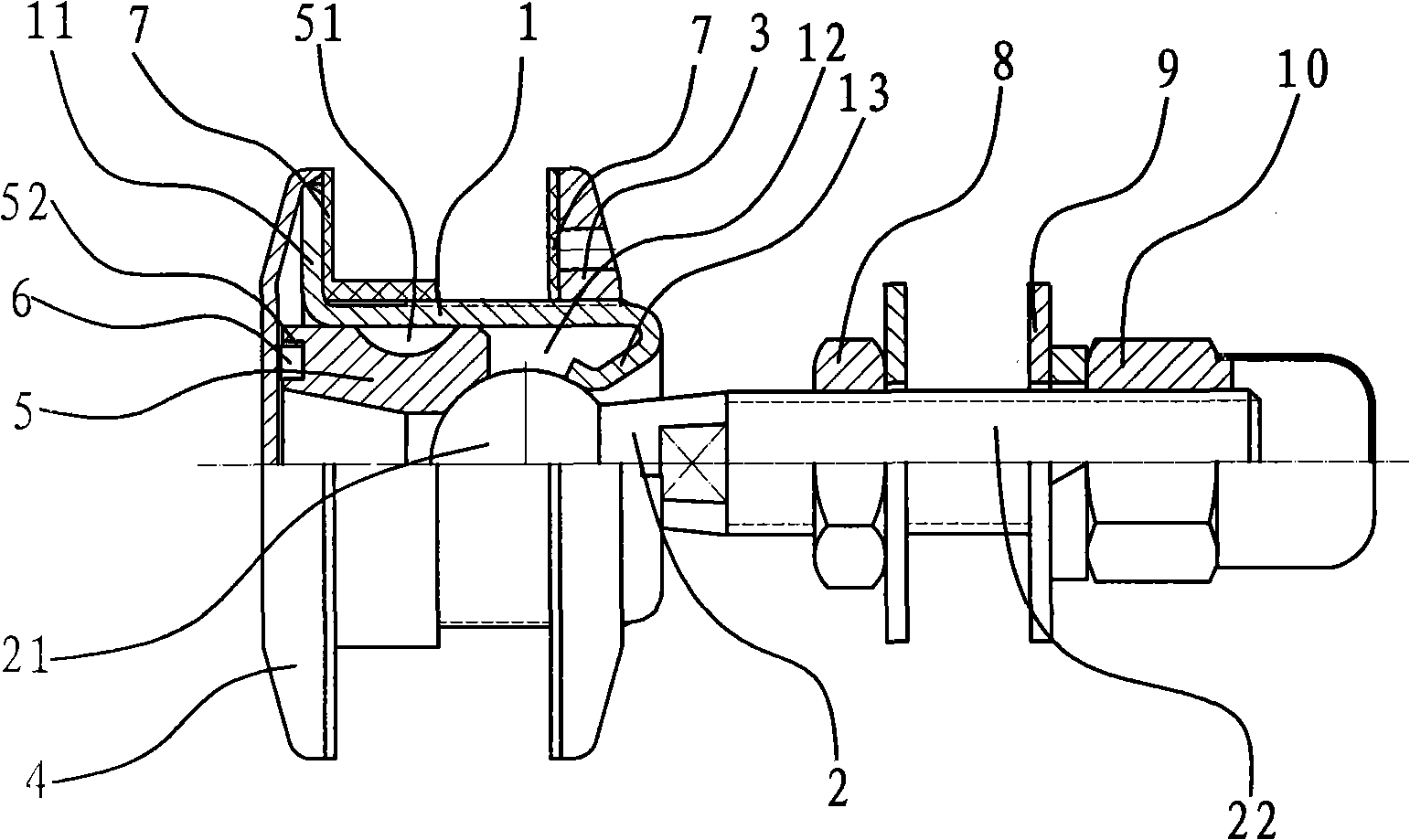

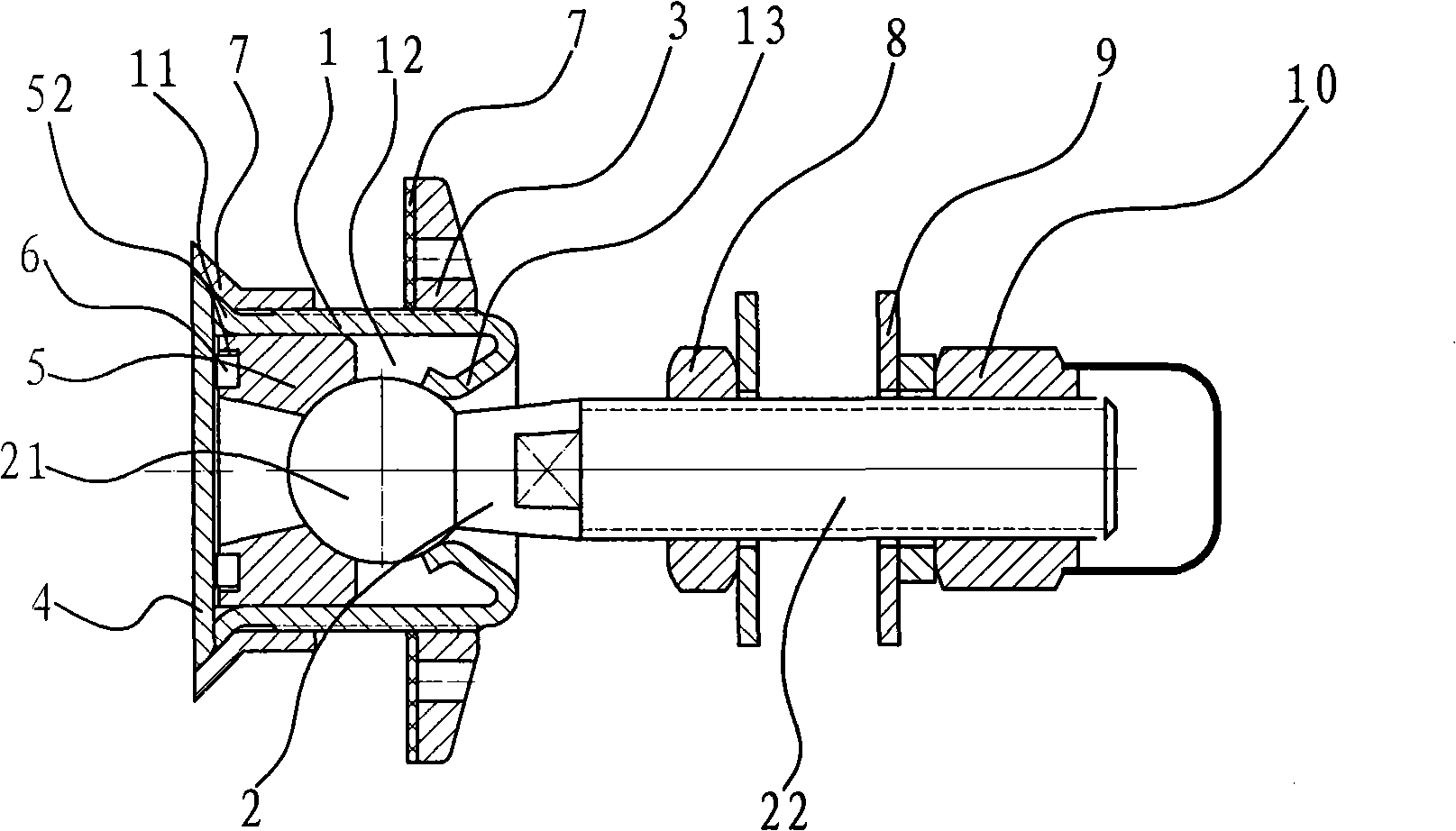

The invention provides a glass curtain wall overlap connector, which comprises a fixing seat and a connecting rod connected with the fixing seat, wherein one end of the fixing seat has a blocking part, while the other end is provided with a locking nut; the inside of the fixing seat is provided with a cavity communicated with the outside; one end of the connecting rod is an expansion part, while the other end is a screw stem part; the expansion part is arranged inside the cavity; the fixing seat also has a necking part with one end face bent inwards and positioned inside the cavity; the minimum diameter of the necking part is more than the maximum diameter of the screw stem part but is less than the maximum diameter of the expansion part; and an end cap is fixed outside the blocking part. The glass curtain wall overlap connector has the advantages that: the necking part is directly arranged on the fixing seat to form an integral structure, thereby obtaining a simple structure and eliminating the hidden danger caused by the use of a constraining piece; the fixing seat is precisely made from a sheet material without adopting a casting technique, and the difference in making process saves a great amount of material cost and production expense; and the necking part has a greater field angle, thereby improving the installation adaptability of the overlap connector.

Description

Glass curtain wall barge joint 【Technical field】 The invention relates to a building connector, in particular to a glass curtain wall barge joint. 【Background technique】 Glass curtain wall is widely used in construction because of its good permeability, beautiful appearance and easy cleaning. The existing glass curtain wall barge joint includes a fixing seat and a connecting rod. One end of the connecting rod is a universal ball head, and the universal ball head is arranged in the inner cavity of the fixing seat, and then a restraining piece is set at the mouth of the inner cavity, so that The universal ball head is fixed in the inner cavity for a certain rotation. This kind of constraint is loosened due to the long-term vibration of the barge joint. In severe cases, the universal ball head is detached and accidents occur. Cause installation and debugging difficulties. The existing barge joints have complex structures, and most of them adopt casting technology, which gre...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E04B2/88

Inventor 蔺耀平吴建平

Owner SHENZHEN GUIHANG IND

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com