Engine of working truck, hydraulic pump controller and method for controlling hydraulic pump

A technology for working vehicles and control devices, applied in the directions of engine control, machine/engine, pump/compressor arrangement, etc., can solve the problems of reduced durability of brake devices, increased brake heat, and reduced discharge flow of hydraulic pumps, etc., to avoid Reduced work efficiency, avoided oil temperature rise, and reduced load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

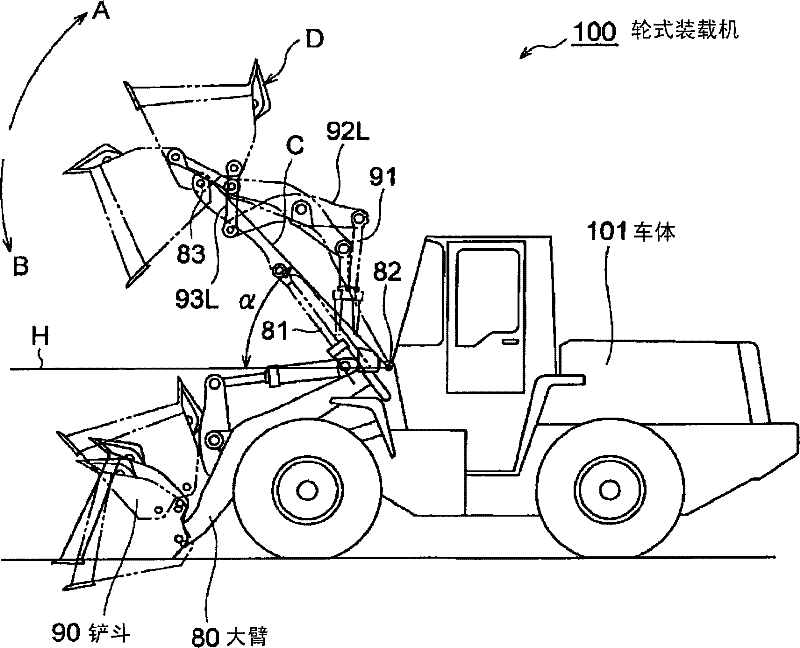

[0049] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

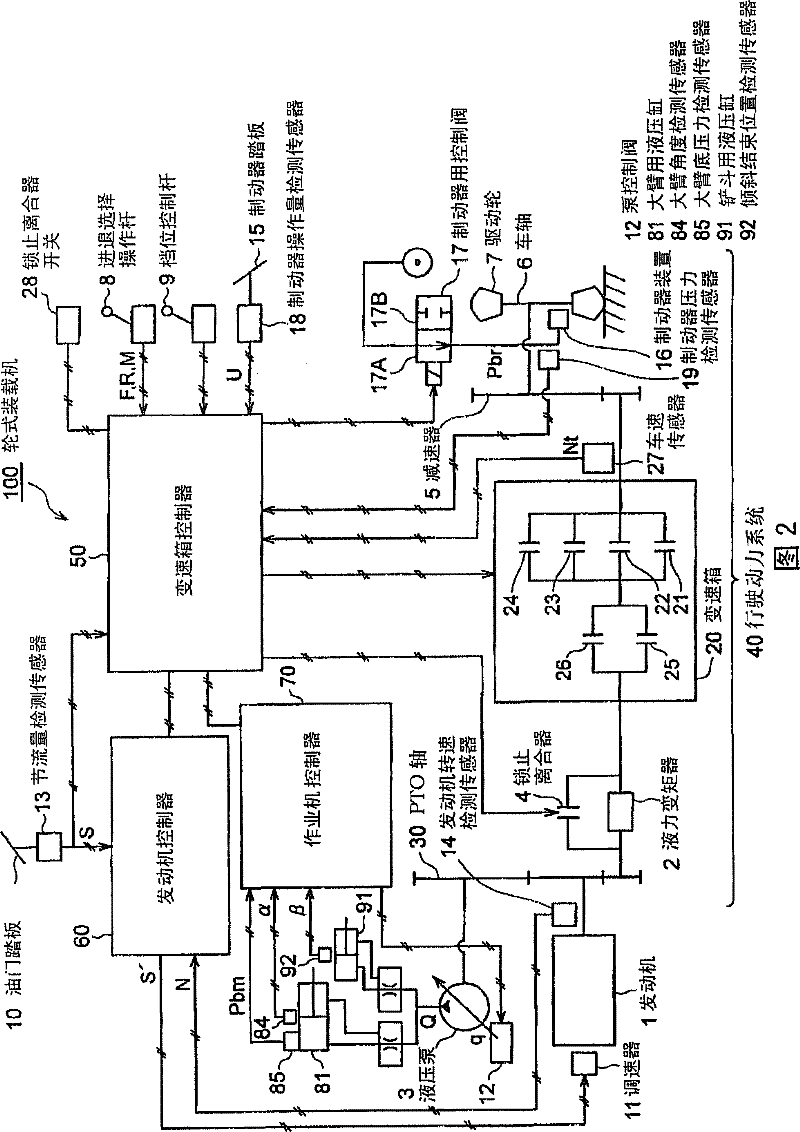

[0050] figure 2 It is a block diagram showing the configuration of the engine and hydraulic pump control device of the work vehicle according to the embodiment, and the part of the present invention shows the configuration of the wheel loader.

[0051] as figure 2 As shown, the wheel loader 100 distributes the power of the engine 1 to the traveling power system 40 and the hydraulic pump 3 , the driving wheels 7 are operated by the traveling power system 40 , and the working machine etc. are operated by the hydraulic pump 3 .

[0052] The output shaft of the engine 1 of the wheel loader 100 is connected to the PTO shaft 30 . The PTO shaft 30 is connected to the torque converter 2 and also connected to the hydraulic pump 3 . A lock-up clutch 4 for locking the torque converter 2 is arranged in parallel on the torque converter 2 along the power transmission path 40 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com