Belt stretcher driven by AC series excitation motor

A technology of tensioning device and exciting motor, applied in the direction of transmission device, electromechanical device, electric components, etc., can solve the problems affecting the normal use of equipment, the rise of belt temperature, the reduction of belt tension, etc., and achieve significant social and economic benefits, stable and stable. The effect of reducing the stability and reducing the positioning error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

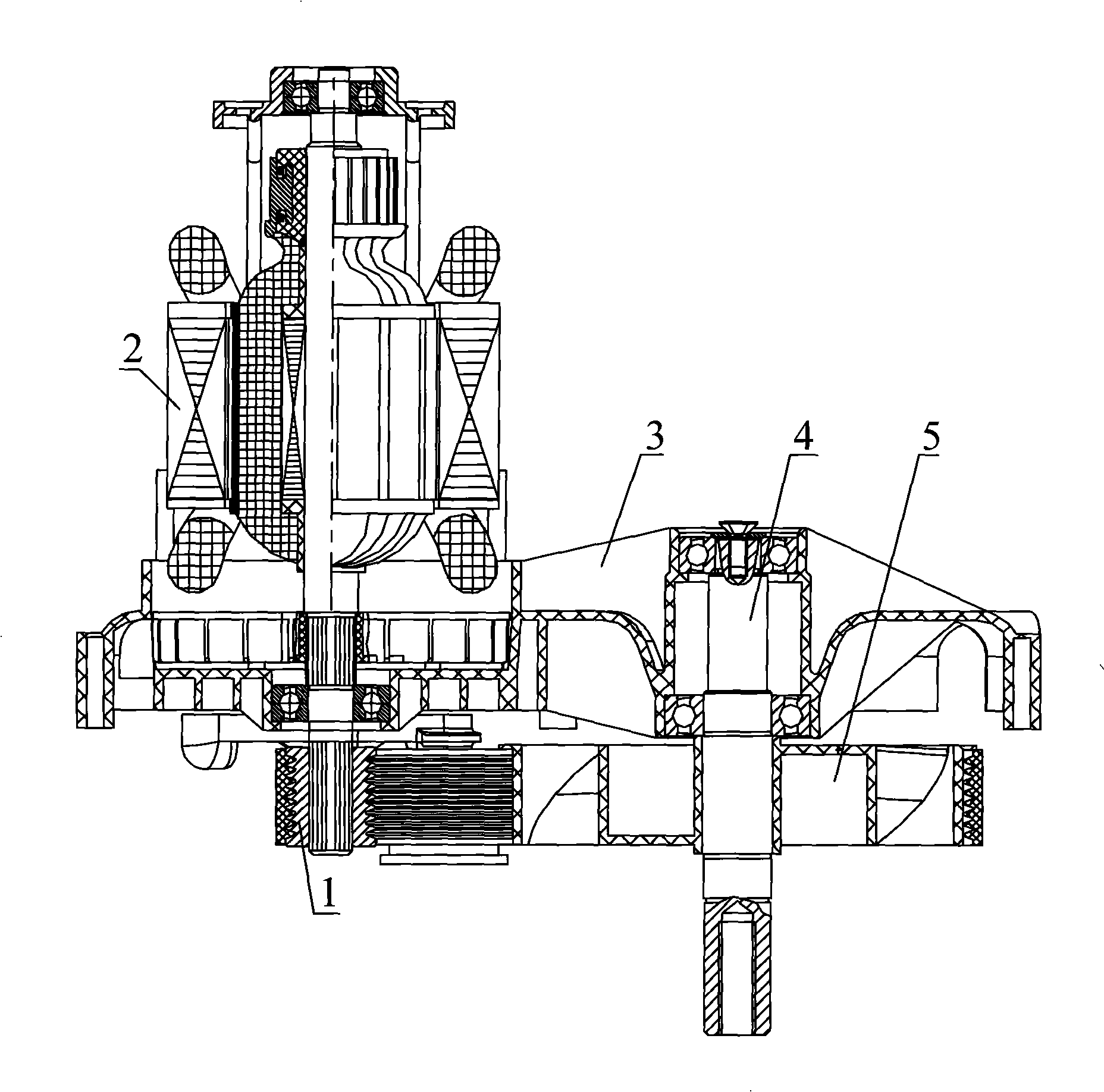

[0020] Such as figure 1 As shown, the schematic diagram of the AC series motor transmission mechanism, the helical gear 1 is connected to the shaft of the motor 2, and is driven to the transmission wheel 5 through the transmission belt, and the transmission wheel 5 is connected to the transmission shaft 4, so its energy is transmitted through the transmission shaft 4 to External machinery (such as blades for lawn mowers).

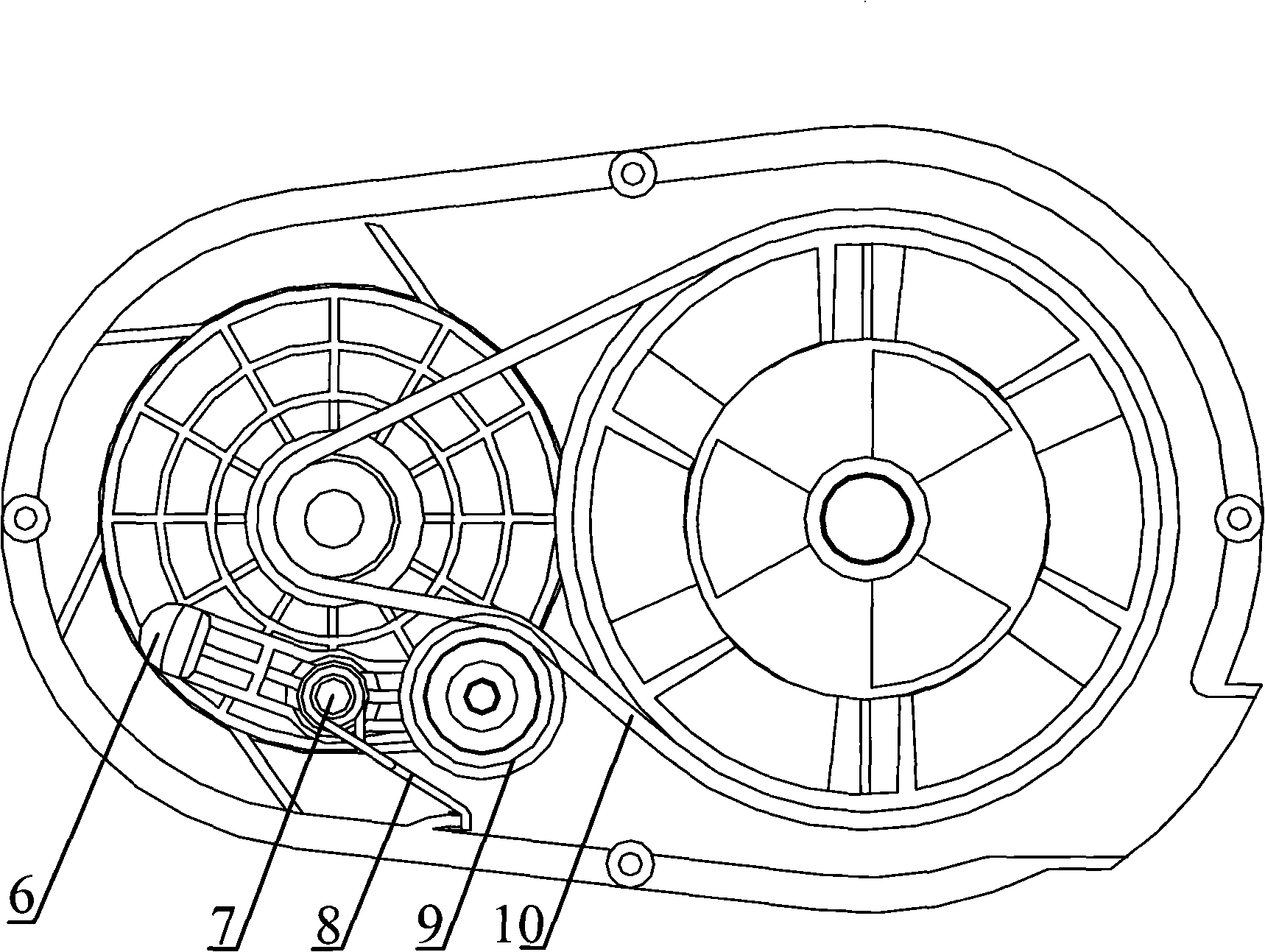

[0021] When the motor 2 is energized, the electric energy of the motor is converted into mechanical energy, which is output through the motor shaft. During the operation, because the belt drive is used, it has slipping phenomenon. In order to prevent and eliminate the slipping phenomenon in the transmission process , the present invention designs a belt tensioning device, such as figure 2 As shown, a positioning pin 7 is set on the base 3 of the motor, the driving lever 6 and the torsion spring 8 are fixed on the positioning pin 7, the driving lever 6 can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com