Polyisocyanate combination and method for preparing rigid isocyanurate foam using the same

A technology of rigid polyurethane and polyisocyanate, which is applied in the field of polyisocyanate composition, can solve the problems of huge investment in equipment and increased manufacturing cost, and achieve the effect of low thermal conductivity and improved thermal conductivity

Active Publication Date: 2008-10-15

NIPPON POLYURETHANE IND CO LTD

View PDF2 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in the method (1) or (2) above, since the obtained isocyanate group-terminated prepolymer itself has a high viscosity, there are problems in that a high-performance mixing head is required in terms of equipment when obtaining a rigid polyurethane foam, Or, in order to obtain a good mixing state in the mixing head, it is necessary to heat the isocyanate group-terminated prepolymer to a temperature higher than necessary, etc., and the investment in equipment is huge or the manufacturing cost is increased.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

Embodiment a-1

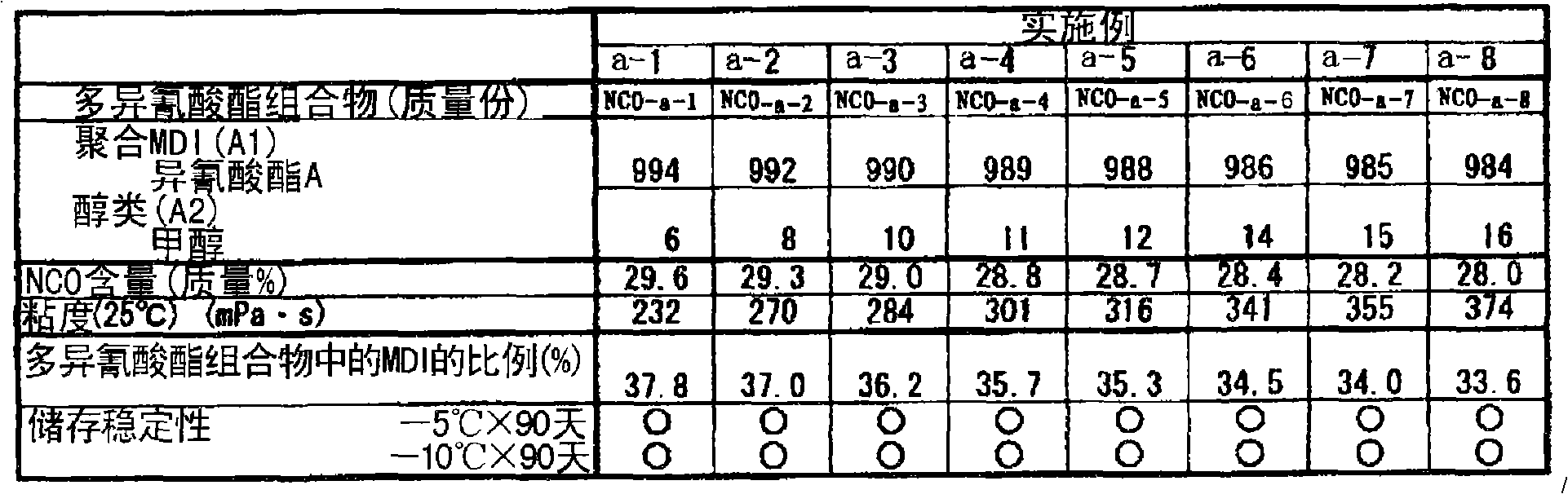

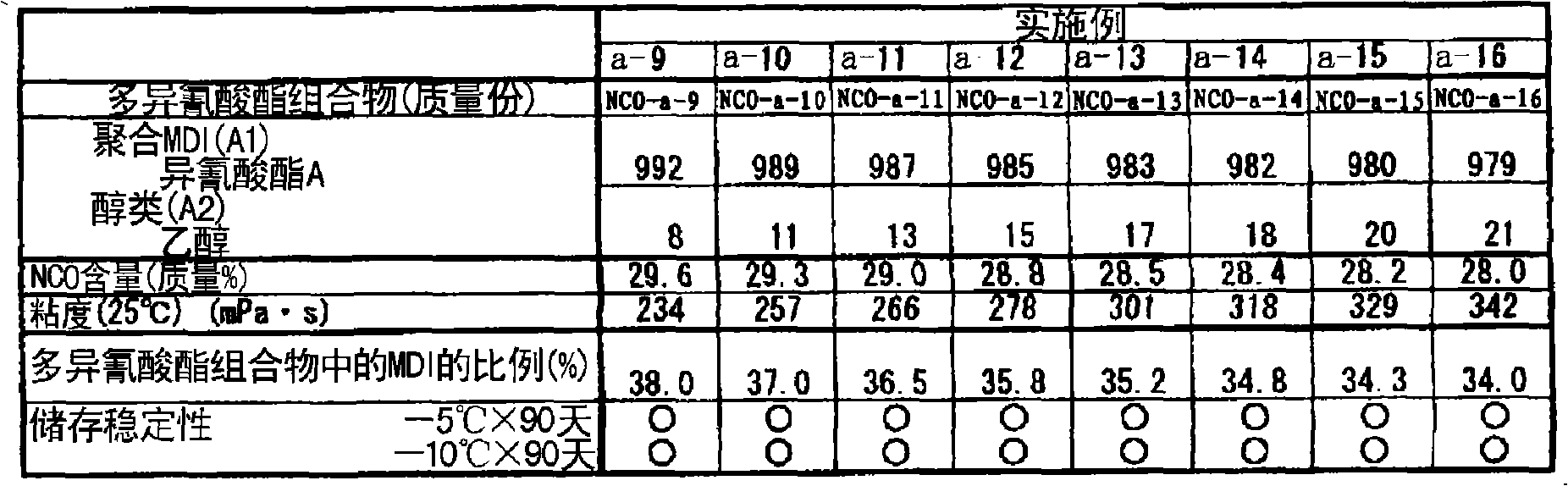

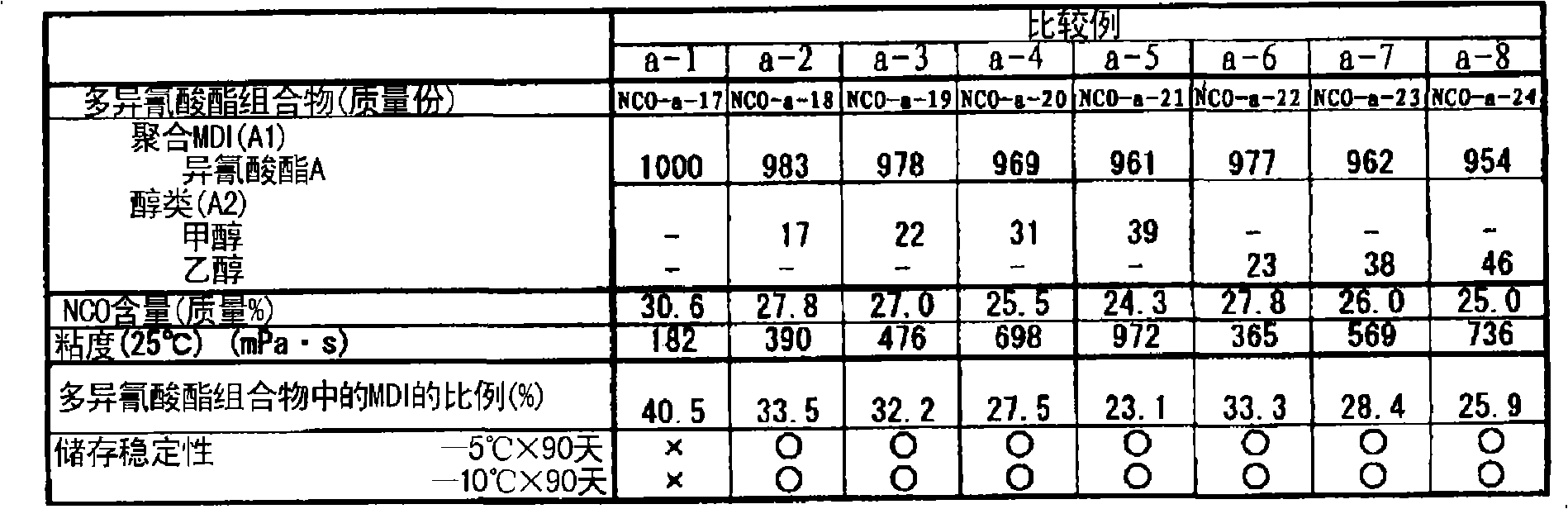

Embodiment a-2~a-16 and comparative example a-1~a-8

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides an isocyanate composite and a preparation method for scleroid polyurethane foam using the same. A preparation method for scleroid polyurethane foam using the hydrocarbon as the vesicant with independent bubbles; the scleroid polyurethane foam has a great storing stability, and the scleroid polyurethane foam can provide the heat conductive performance and great mechanical physical property (size stability and so on) for the scleroid polyurethane foam with the independent bubbles. The method uses the isocyanate composite composed by the polymerized MDI and alcohols with molecular weight less than 150 to prepare the scleroid polyurethane foam with the independent bubbles.

Description

Polyisocyanate composition and method for producing rigid polyurethane foam using same technical field The present invention relates to a polyisocyanate composition for producing a rigid polyurethane foam with closed cells, and a method for producing a rigid polyurethane foam with closed cells using the composition. More specifically, it relates to excellent foam properties with excellent low thermal conductivity and closed cells, and by using a low-viscosity polyisocyanate composition, the mixing property is sufficiently good even with a currently used mixing head. A method for producing rigid polyurethane foam with independent cells that ensures uniform fine cells. In addition, in the present invention, unless otherwise specified, "rigid polyurethane foam" includes the concept of "isocyanurate-modified polyurethane foam". In addition, "having closed cells" in the present invention means that the closed cell rate based on ASTMD2856 is 75% or more (including 75%). Backgrou...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08G18/72C08G18/06C08J9/02C08K5/01

Inventor 菅野晶安斋俊之平田邦生

Owner NIPPON POLYURETHANE IND CO LTD

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com