Quick assembled type platform

A prefabricated and fast technology, applied in the direction of building structure support, building structure support, building structure support scaffolding, etc., can solve the problems of time-consuming and labor-intensive installation and dismantling, and achieve the goal of preventing overload use, quick installation and disassembly, and ensuring safety Effect

Inactive Publication Date: 2010-11-03

CHONGQING NO 3 CONSTR

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In order to overcome the time-consuming and labor-intensive installation and dismantlement of the existing platform and the lack of alarm devices, the present invention provides a platform with simple structure, quick operation and automatic load limit alarm

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

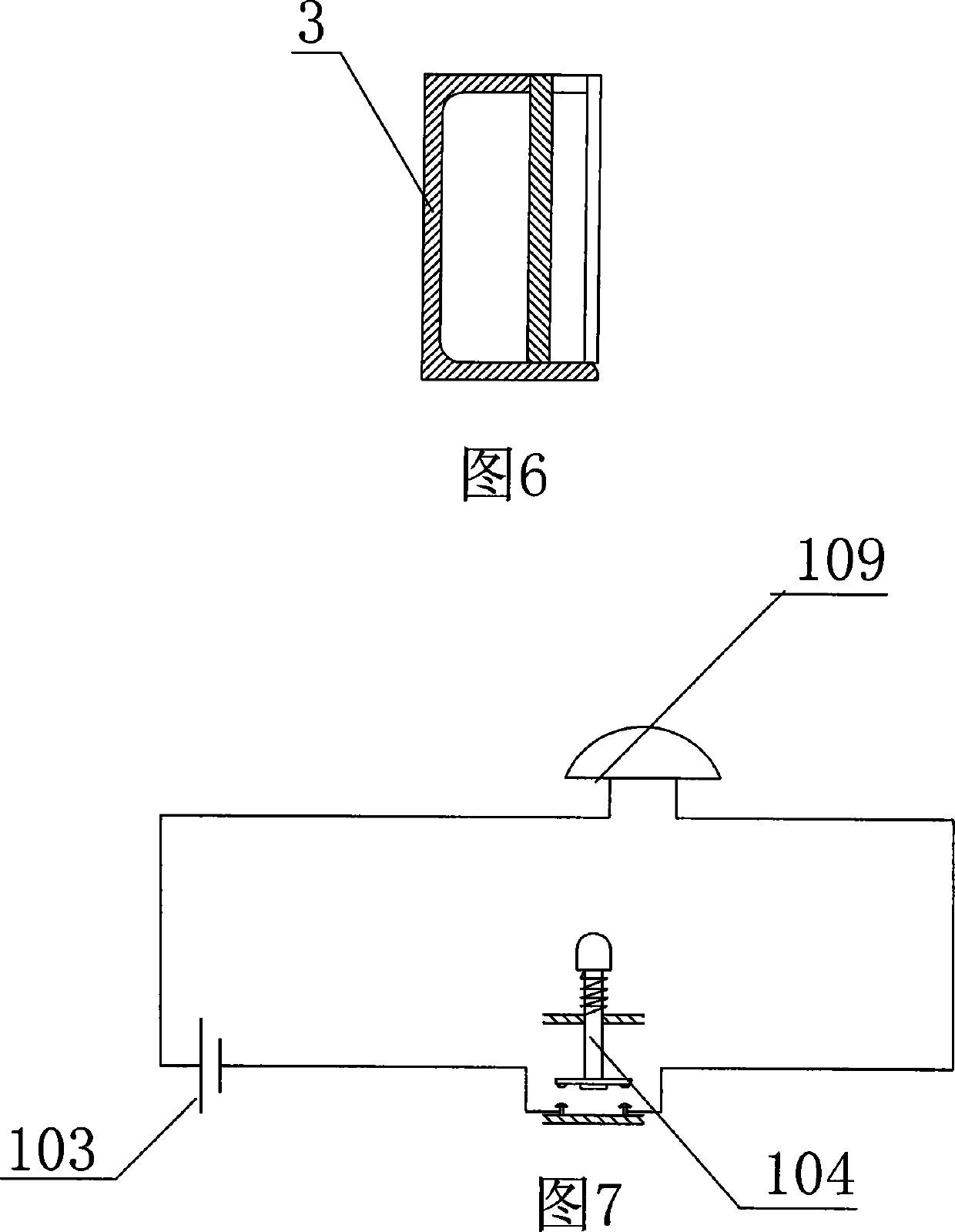

The invention discloses a fast assembly-type platform which comprises a main stayed-cable (1), a subsidiary stayed-cable (2), main beams (3) and cross beams (4). The front end of the main beam is provided with a main stayed-cable (5) and a subsidiary stayed-cable (6) while the rear end thereof is provided with a jack (7); when in use, multiple groups of cross beams (4) are connected between two groups of main beams (3) that are relatively parallel; the upper ends of the main stayed-cable (1) and the subsidiary stayed-cable (2) are respectively connected with a building (8); the lower end of the main stayed-cable (1) is connected with the main stayed-cable (5), and the lower end of subsidiary stayed-cable (2) is connected with the subsidiary stayed-cable (6); the rear ends of the main beams (3) are positioned on the building (8); the jack (7) is supported on the structure of the building (8). The fast assembly-type platform is characterized in that: the connection between the main beams (3) and the cross beams (4) is realized by an embedded connecting device (9) which comprises a C-shaped connecting seat (91) arranged on the main beams (3) and a T-shaped connector (92) arranged on the cross beams (4), wherein, the C-shaped connecting seat (91) is matched with the T-shaped connector (92) by clearance. The fast assembly-type platform has the advantages of simple operation, high efficiency, safety and reliability and low cost.

Description

technical field The invention relates to a material unloading platform used in building construction, in particular to a platform which can be assembled and disassembled quickly and can carry out load alarm. Background technique When the building construction unit is carrying out the main construction of multi-storey, high-rise and super high-rise buildings, it needs to transfer the formwork and its supporting system materials in the floor to the upper floor. At present, the more common method is to install a certain number of platforms on the floor where the formwork is removed. The platforms are fixed on the building with steel wire ropes and protrude outwards, and the removed formwork, steel pipes, fasteners and other materials are stacked on the platform. , and then transferred to the construction floor by tower crane. Some construction enterprises adopt the structure of integrated welding and forming of section steel, but due to the large size of the platform (generall...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): E04G21/00E04G3/00G08B21/18

Inventor 熊渝兴刘信君邹红鲍安红陈厚安

Owner CHONGQING NO 3 CONSTR

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com