Knitting needle of computer flat knitting machine

A flat knitting machine and knitting needle technology, which is applied in knitting, weft knitting, textile and paper making, etc., can solve the problems of high driving power of the machine head, increase the manufacturing cost, increase the floor space, etc., and reduce the volume and is not easy to wear. , the effect of saving manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to enable the examiners of the patent office, especially the public, to understand the technical essence of the present invention more clearly, and to make the advantages and effects of the present invention clearer, the applicant will describe the specific implementation of the present invention in detail below in conjunction with the accompanying drawings , but all descriptions of the implementation manners shall not be regarded as limitations on the solutions of the present invention, and any equivalence changes in form but not in substance shall be deemed to belong to the scope of the technical solutions disclosed in the present invention.

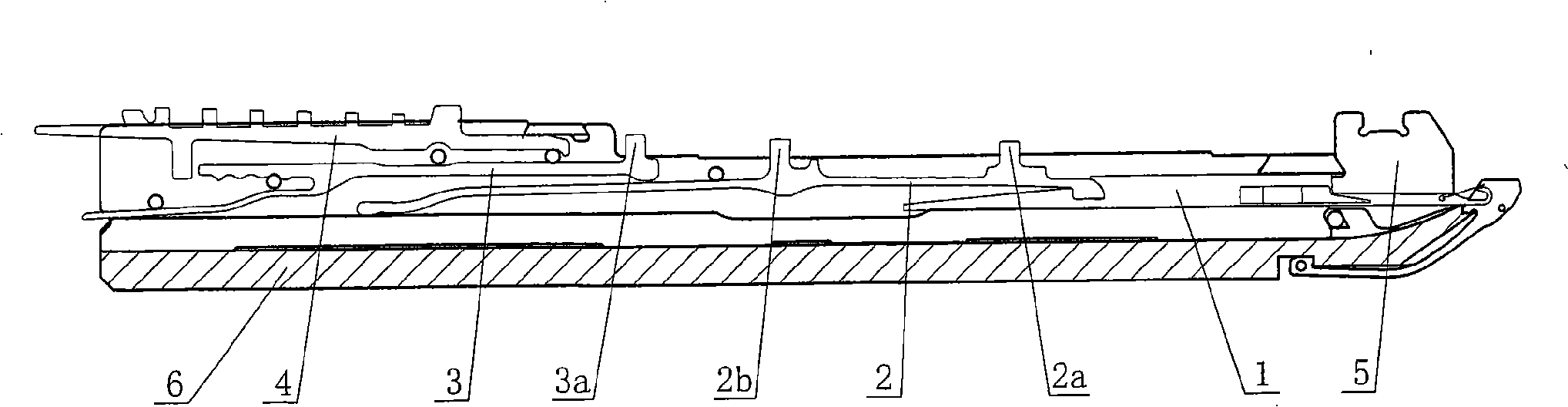

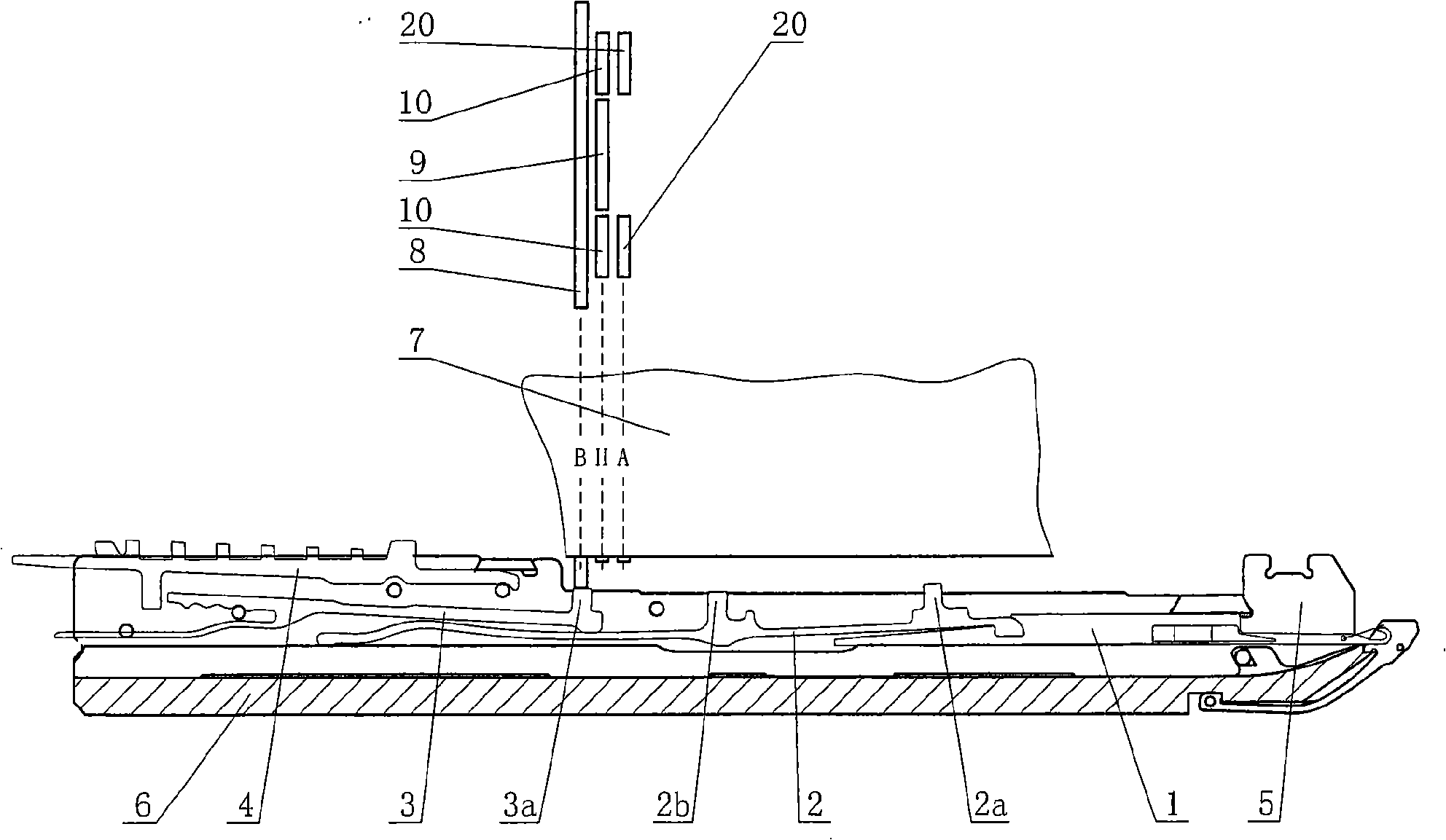

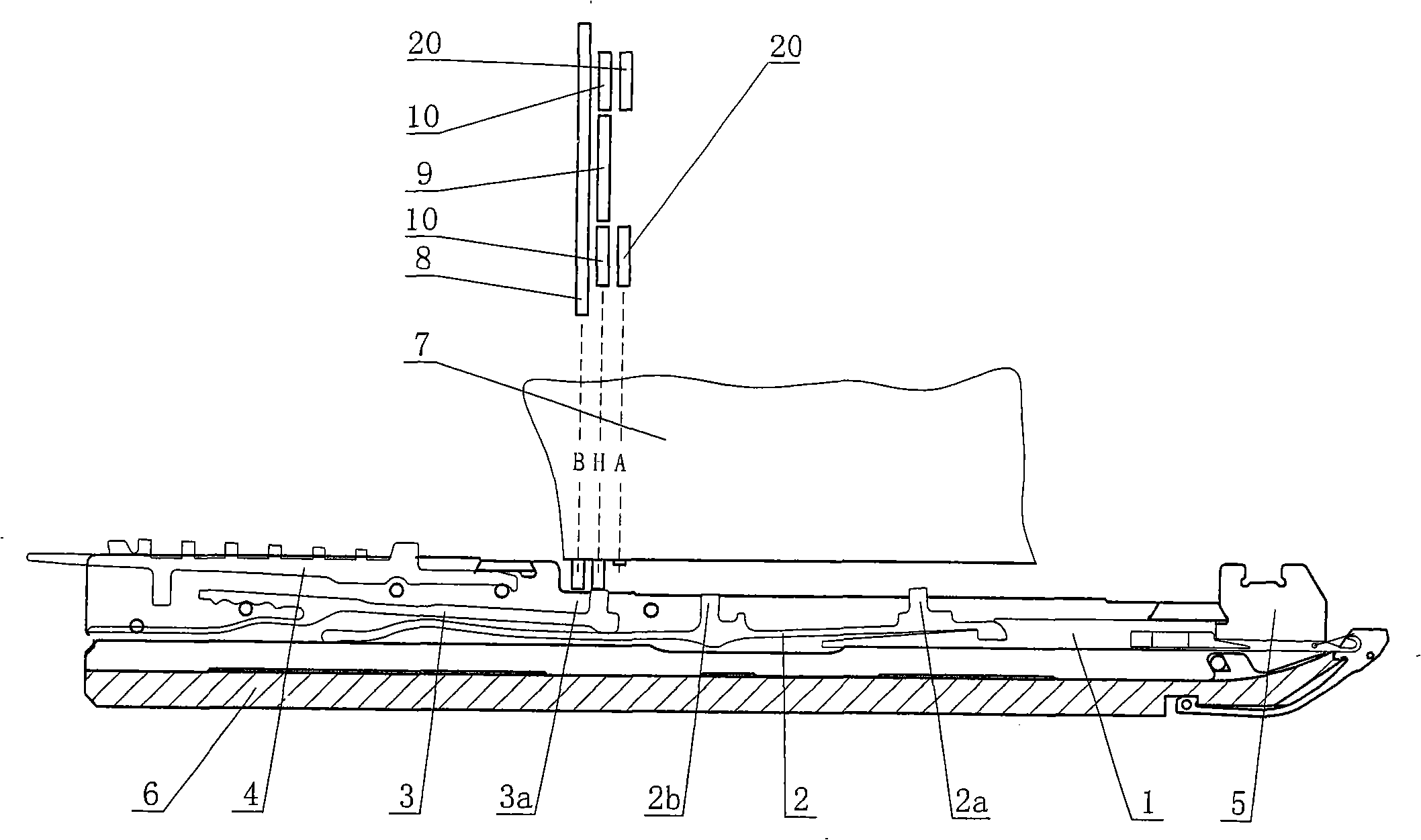

[0035] please see Figure 5, taking the current illustrated position state as an example, the structure and function of the hook head 14 at the right end of the knitting needle 1 have no difference from the prior art, and as one of the specific means in the technical solution of the present invention, it is in this knitt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com