Hydrocarbon resin polymer material viscosity on-line continuous detecting method

A petroleum resin and detection method technology, applied in the direction of DC flow characteristic measurement, special data processing applications, instruments, etc., can solve the problems of slow detection speed and high price, and achieve low cost, low equipment investment, accurate and reliable measurement information Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

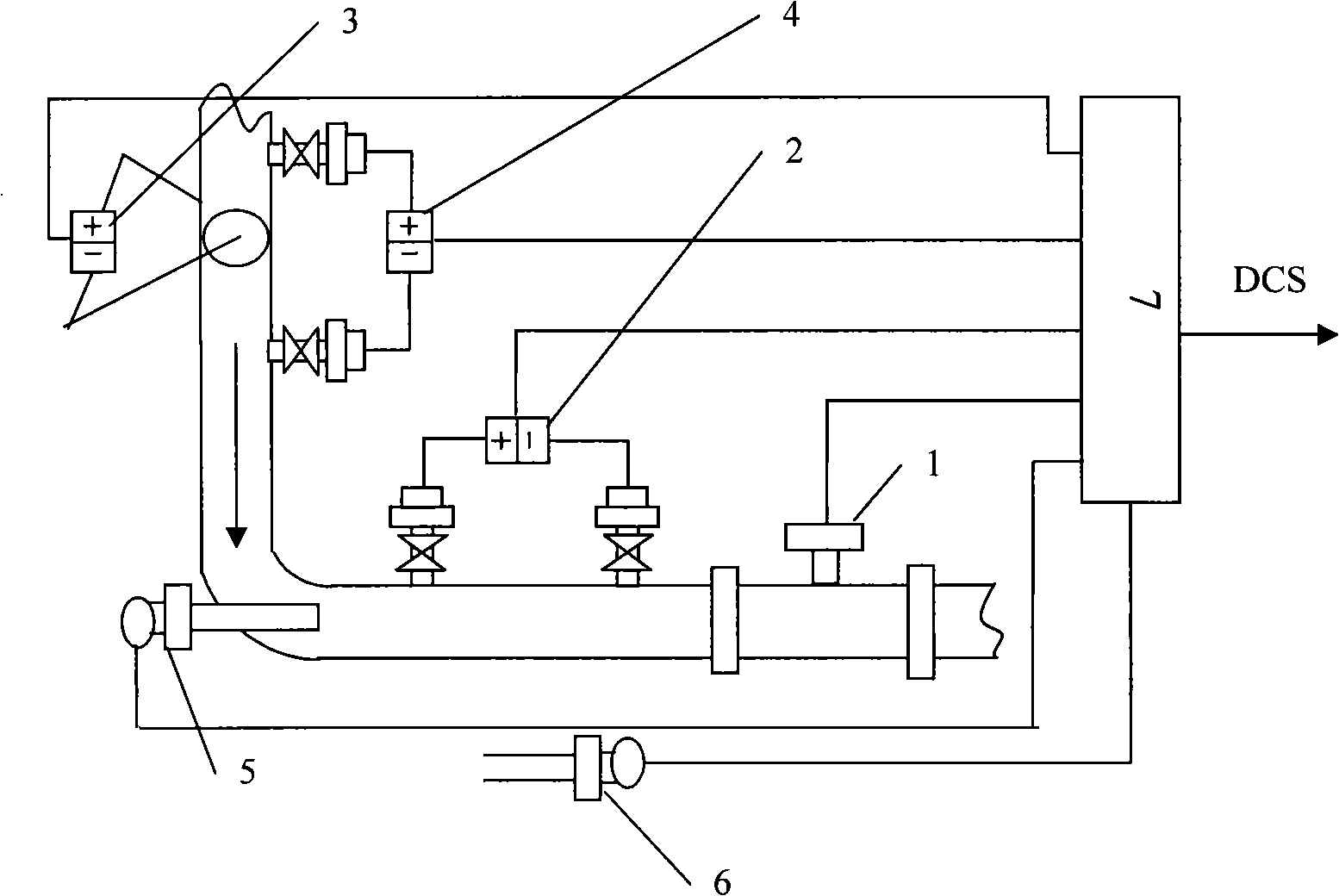

[0024] Taking petroleum resin in a polymerization unit reactor as an example, the method for measuring its viscosity at 120° C. is further described in the present invention.

[0025] (1) Installation of measuring instruments

[0026] Materials such as figure 1 Flow in the direction of the arrow in the middle. When selecting the installation position of the pipeline, try to ensure that the pipeline is filled with materials to ensure the authenticity of the data measured by each detector. The mass flow meter 1 is installed horizontally on the pipeline, and is used to measure the mass flow of the material in real time, and the unit is ton / hour (or other standard units). During the flow process, due to the viscosity characteristics of the material, the friction between the material and the pipeline will cause a certain pressure drop during the flow of the pipeline. Different material viscosities will produce different pressure drops. Therefore, a horizontal differential pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com