The packer for repairing crack in concrete body

A technology of structure and stuffer, which can be applied to the device for coating liquid on the surface, building maintenance, building construction, etc., and can solve the problem of stuffer position (uneven depth, etc.)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

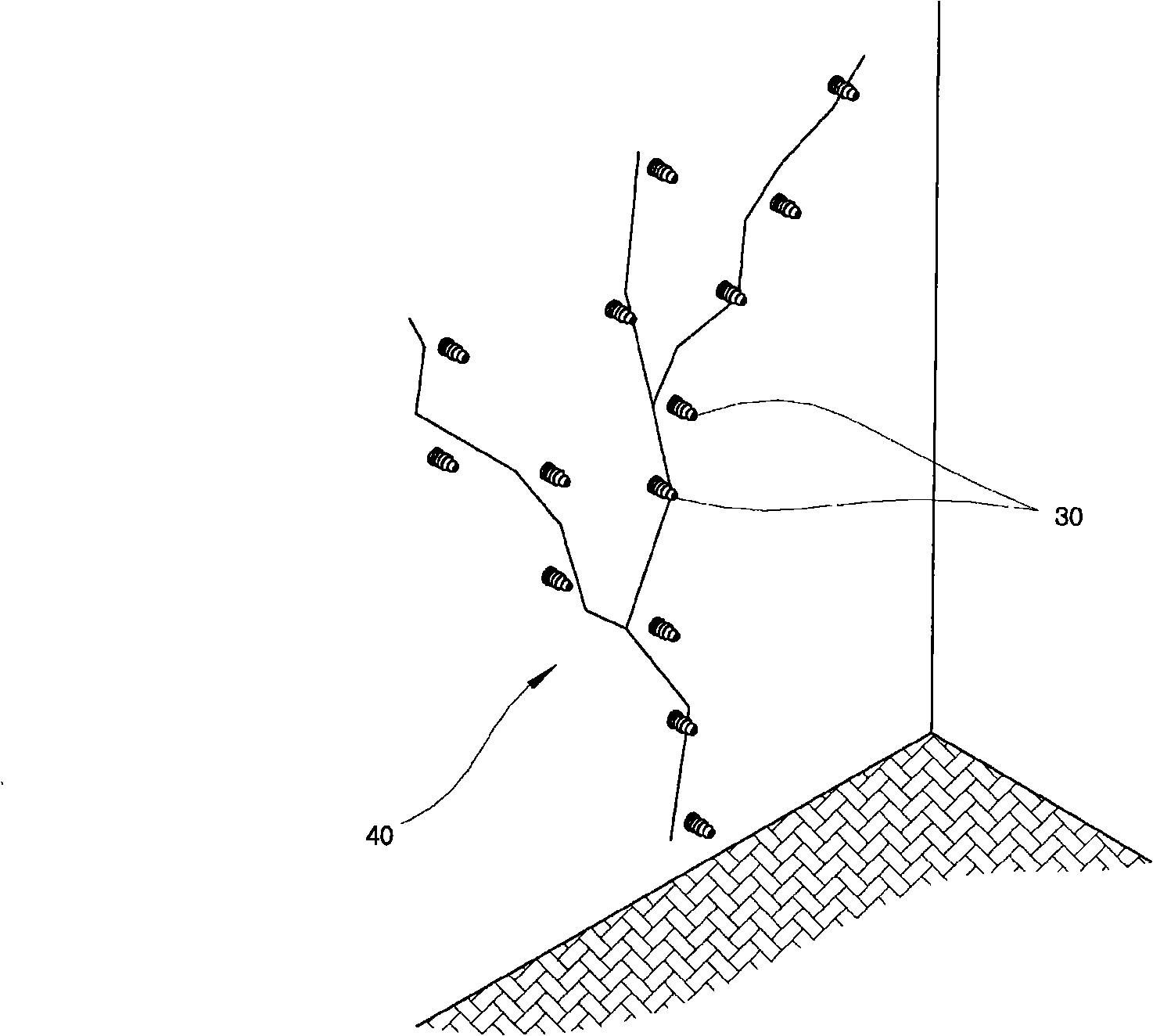

[0021] [19] Preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

[0022] [20] [First embodiment]

[0023] [21] The obturator 30 of the present invention includes the injection body 10 and the flexible sleeve 20 assembled together. An inflow channel 11 is formed through the injection body 10 in the longitudinal direction. A joint portion 12 is formed at one end of the injection body 10, and a plurality of extension units 13 are continuously formed at the other end of the injection body 10, each extension unit having a trapezoidal section such that its diameter gradually increases from its front end to its rear end. A backflow prevention groove 11' having a larger diameter than the inflow passage 11 is formed at an end of the inflow passage 11 opposite to the joint portion 12, and a backflow prevention unit 17 including a compression spring 17b and a spherical check ball 17a is formed in the backflow preven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com