Paper-making pulping method and apparatus

A technology of pulping and screw shaft, which is applied in the field of low energy consumption and pollution-free paper pulping method and its device, can solve the problems of turbidity, unfavorable farmland irrigation, drinking water for humans and animals, and maggots everywhere, so as to improve the pulp yield and save investment Less, the effect of solving the shortage of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

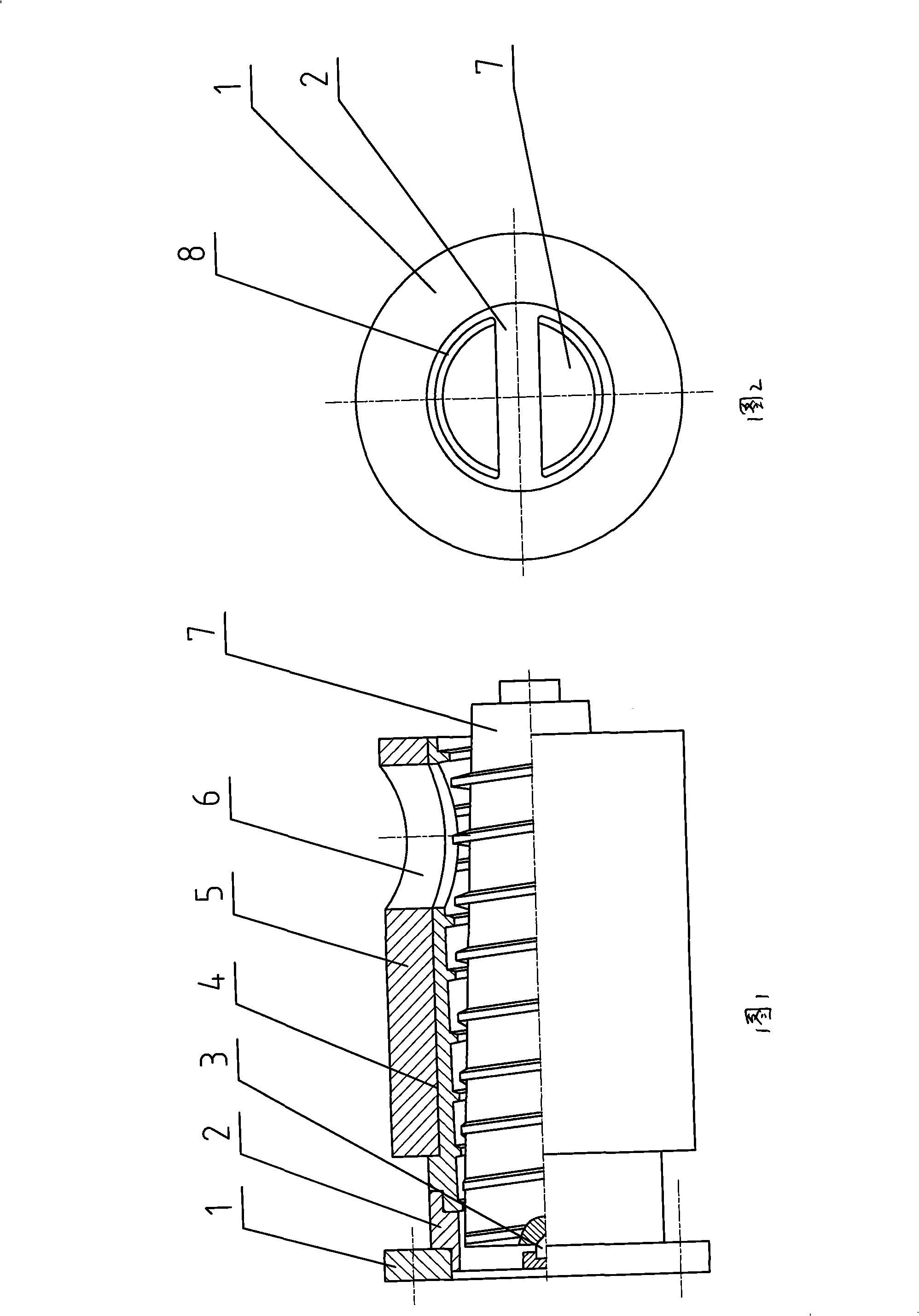

[0014] Specific embodiments of the present invention are described with reference to the accompanying drawings.

[0015] As shown in the drawings: the pulping device includes a main body 5 and a motor. The main body 5 is provided with a feed port 6, and the cylinder is arranged in the main body 5. In the cylinder, a screw shaft 7 is arranged. One end of 7 is connected to the motor, and the shaft of the screw shaft 7 is a tapered structure whose diameter gradually increases from the feed port 6 to the discharge port 8. This structure can make the gap between the screw shaft and the inner wall of the cylinder open from the feed port 6 From the position to the discharge port 8, it decreases successively. There is a spiral groove on the inner wall of the cylinder, and the depth of the spiral groove gradually decreases from the inlet 6 to the outlet 8. This structure can make the gap between the helical teeth on the screw shaft 7 and the spiral groove on the inner wall of the cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com