3-D triangle open mouth coiling iron core

A triangular, wound iron core technology, used in the manufacture of inductors/transformers/magnets, electrical components, transformer/inductor components, etc. The problem is to achieve complete symmetry of the three-phase magnetic circuit, improve production efficiency, and achieve good process performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] specific implementation plan

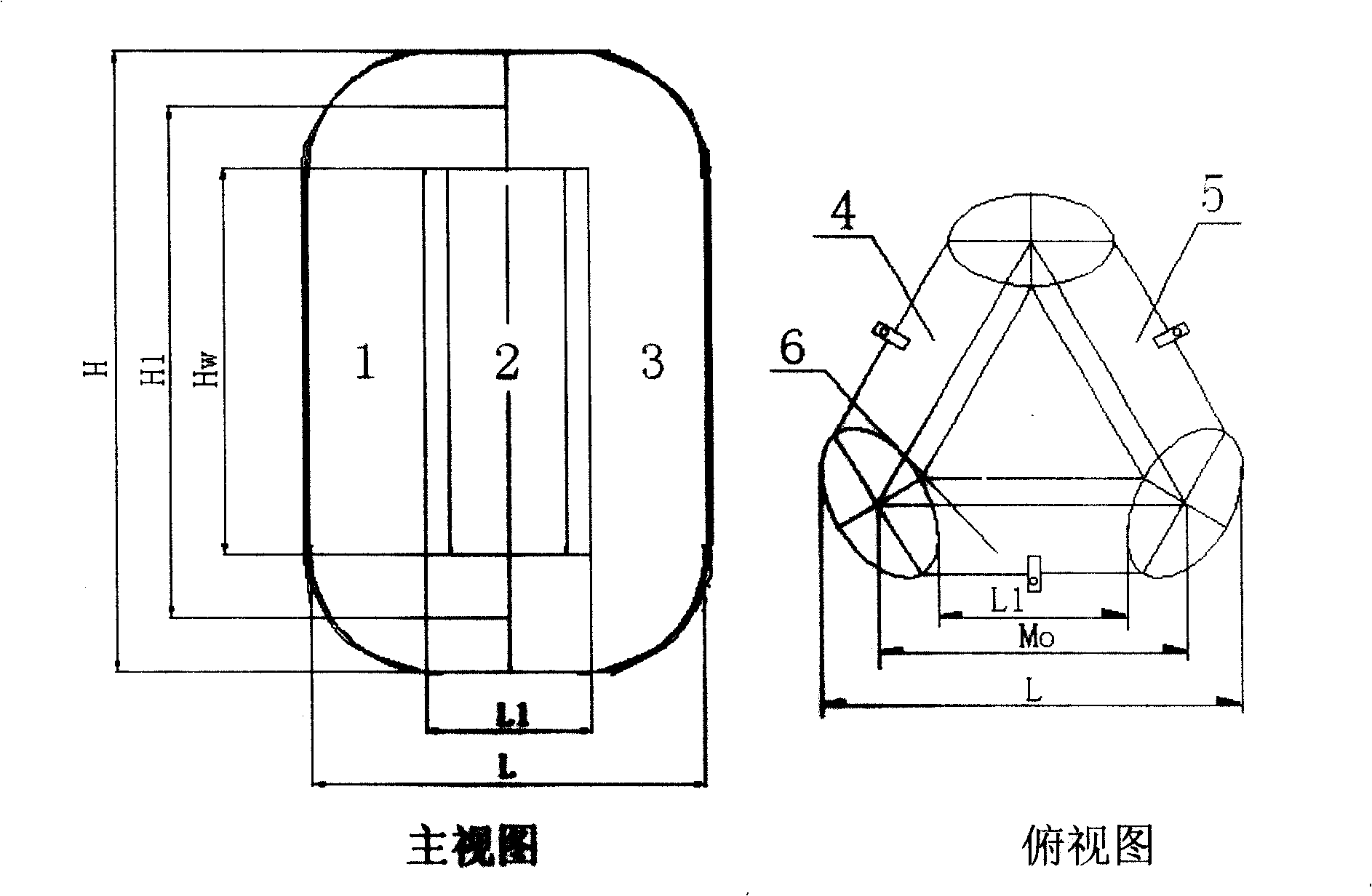

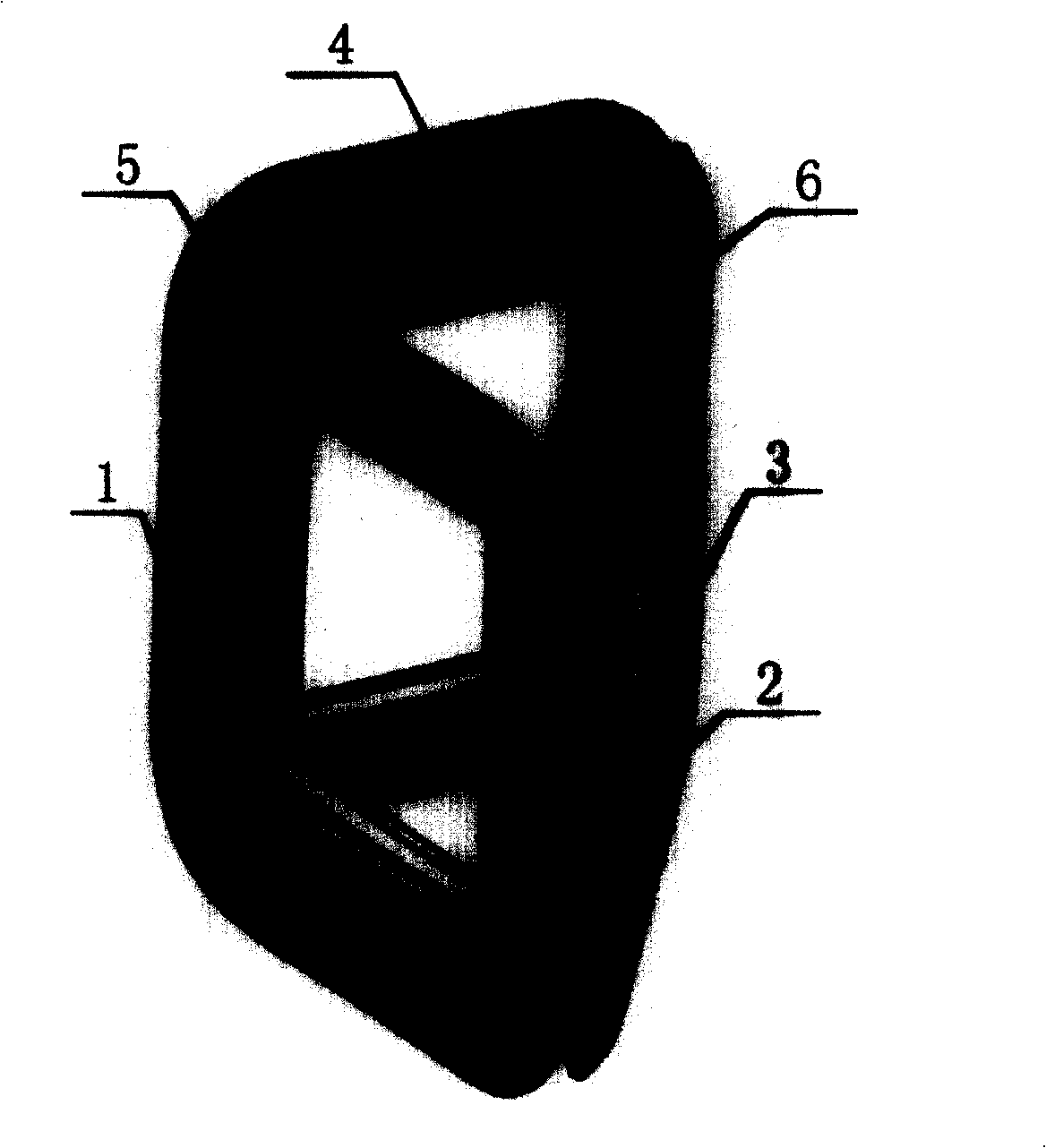

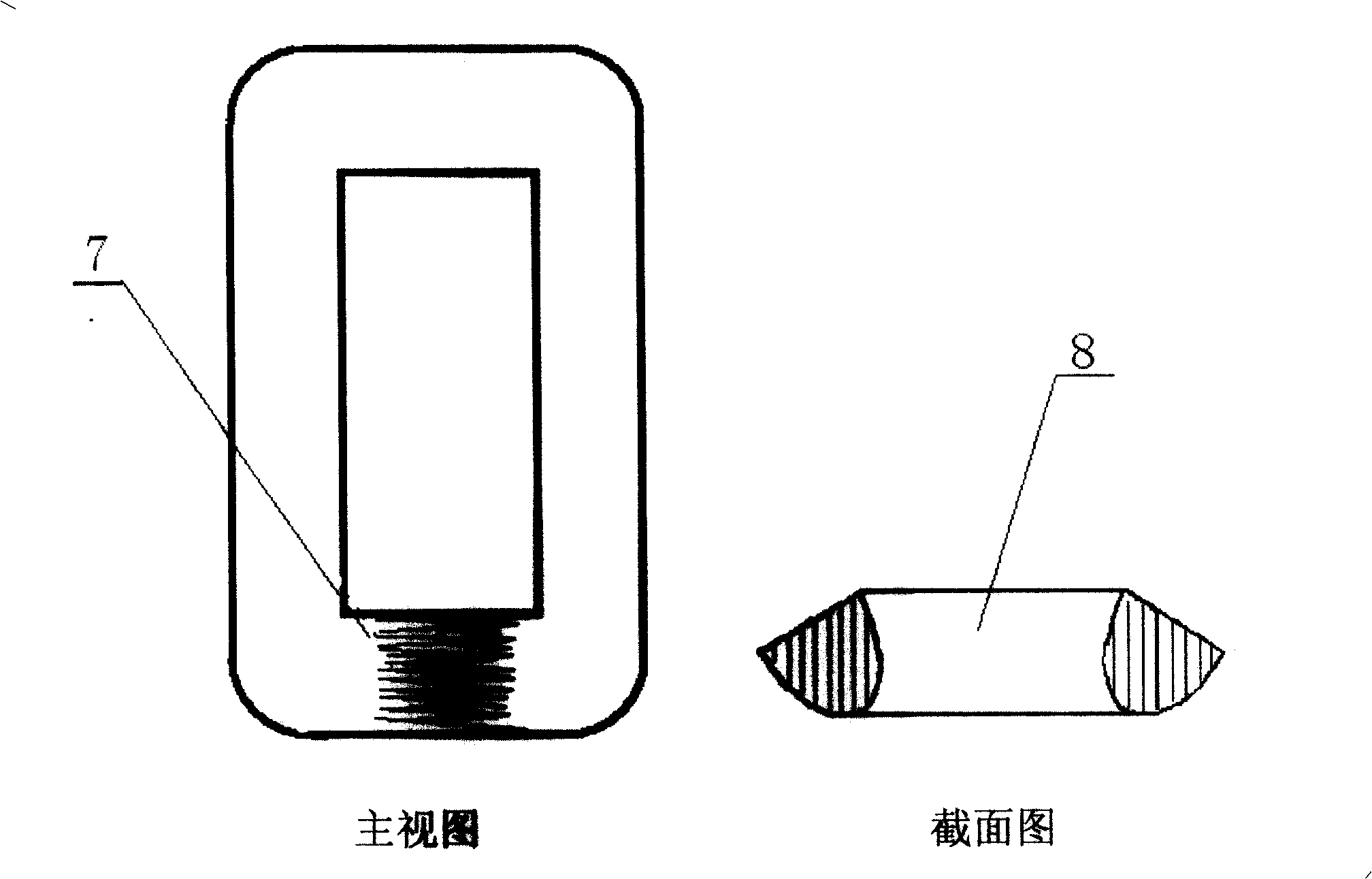

[0018] see figure 2 , the iron core adopts three single-phase open-rolled iron cores (4)~(6) of the same shape to be assembled into a three-dimensional triangular iron core according to the angle of the center angle of 120°, and the coils can be set on three columns (1)~ In (3), the cross-sections of the three core columns of the assembled iron core are all oval or polygonal (circumscribed oval). The three single-phase iron cores used to wind the entire iron core are all formed by continuous winding of silicon steel strips after cutting, instead of cutting the wound iron cores layer by layer. see image 3 , Figure 7 , each single-phase open coil core is made of silicon steel sheet strips drawn by a curved cutting machine, and is made under the winding of a numerically controlled open core winding machine. The core opening gaps are regularly and evenly distributed, and the fracture When the position is at the lower yoke (7), the shape...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com