Method and device for utilizing flow separated from oil gas water separator for integral generation

A separator, oil-gas-water technology, applied in the directions of hydropower generation, fluid extraction, safety devices, etc., can solve the problem of energy waste of separators, and achieve the effect of reducing consumption and realizing energy saving and emission reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

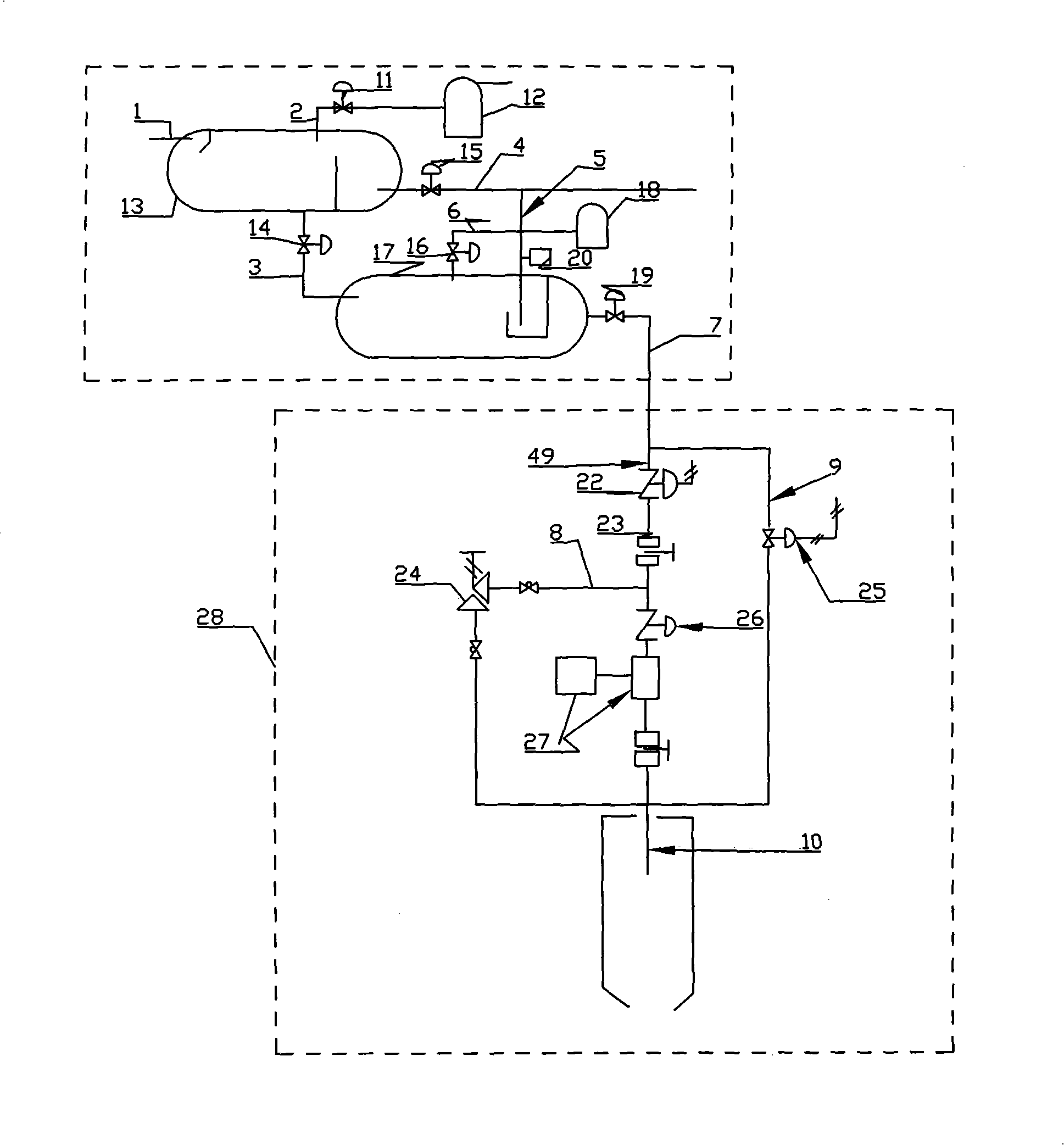

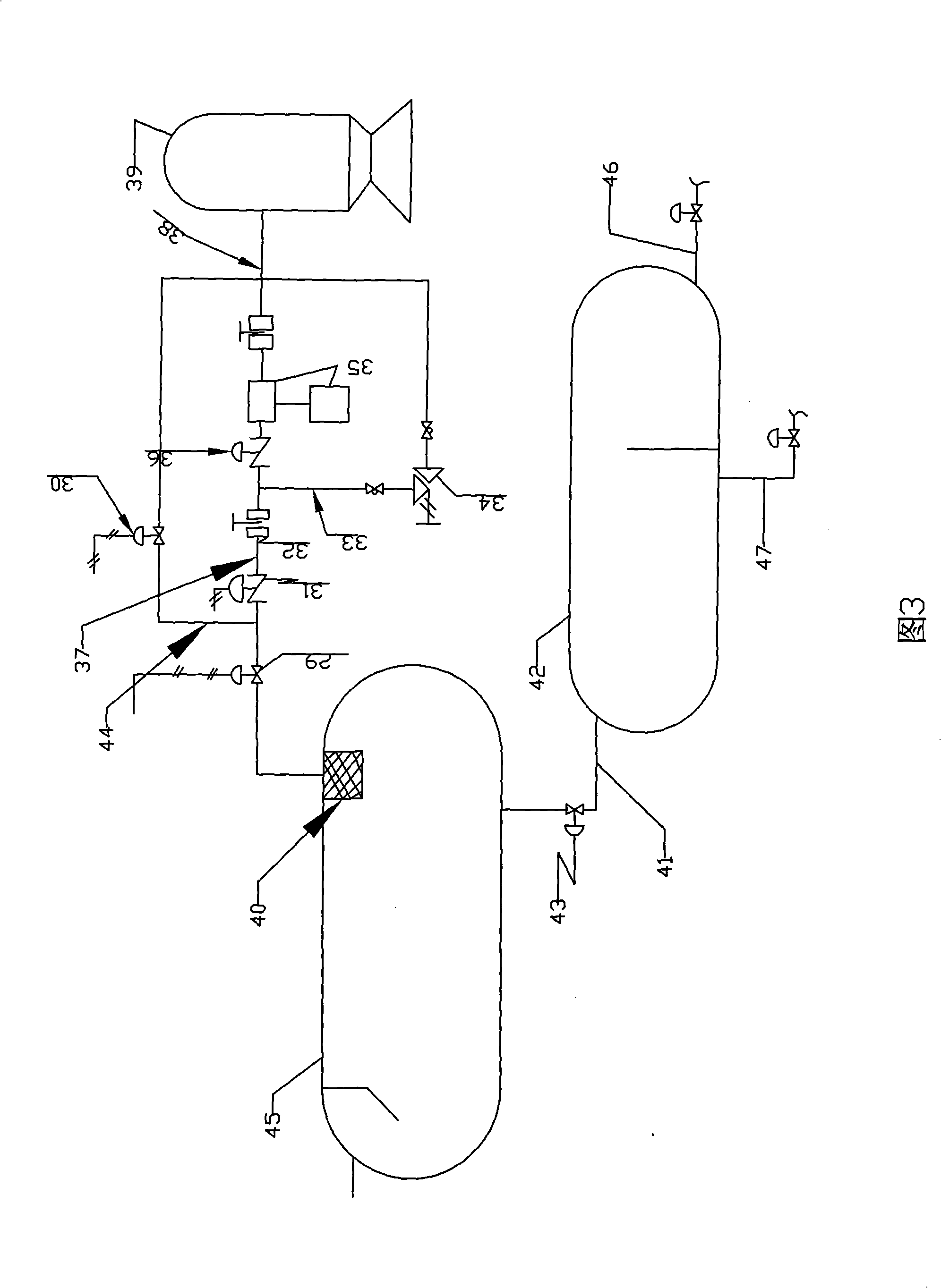

[0139] refer to Figure 1 to Figure 4 , the present invention is implemented like this:

[0140] The components of the method for generating electricity by using the excess pressure, excess energy and waste heat at the outlet of the oil-gas-water separator in the present invention include: an oil-gas-water primary separator and an oil-gas-water secondary separator, a water outlet pipeline, an oil outlet pipeline, an exhaust pipeline, an oil outlet pressure control valve, Water outlet control valve, gas outlet control valve, hydroelectric generator, pressure safety valve, bypass pipeline, geothermal power generation unit including: steam generator, steam turbine, condenser, circulation pump, geothermal generator.

[0141] Fig. 2 is a schematic diagram of the process flow of generating electricity from the outlet water of the separator of the present invention. The principle of implementing the method of the present invention is: the oil-gas-water mixture produced in the format...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com