Wave-dissipating block

A wave absorbing and leg technology, applied in the field of wave absorbing blocks, can solve the problems of limited stability and porosity, and achieve the effect of reducing the amount of concrete, reducing the cost, and increasing the porosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

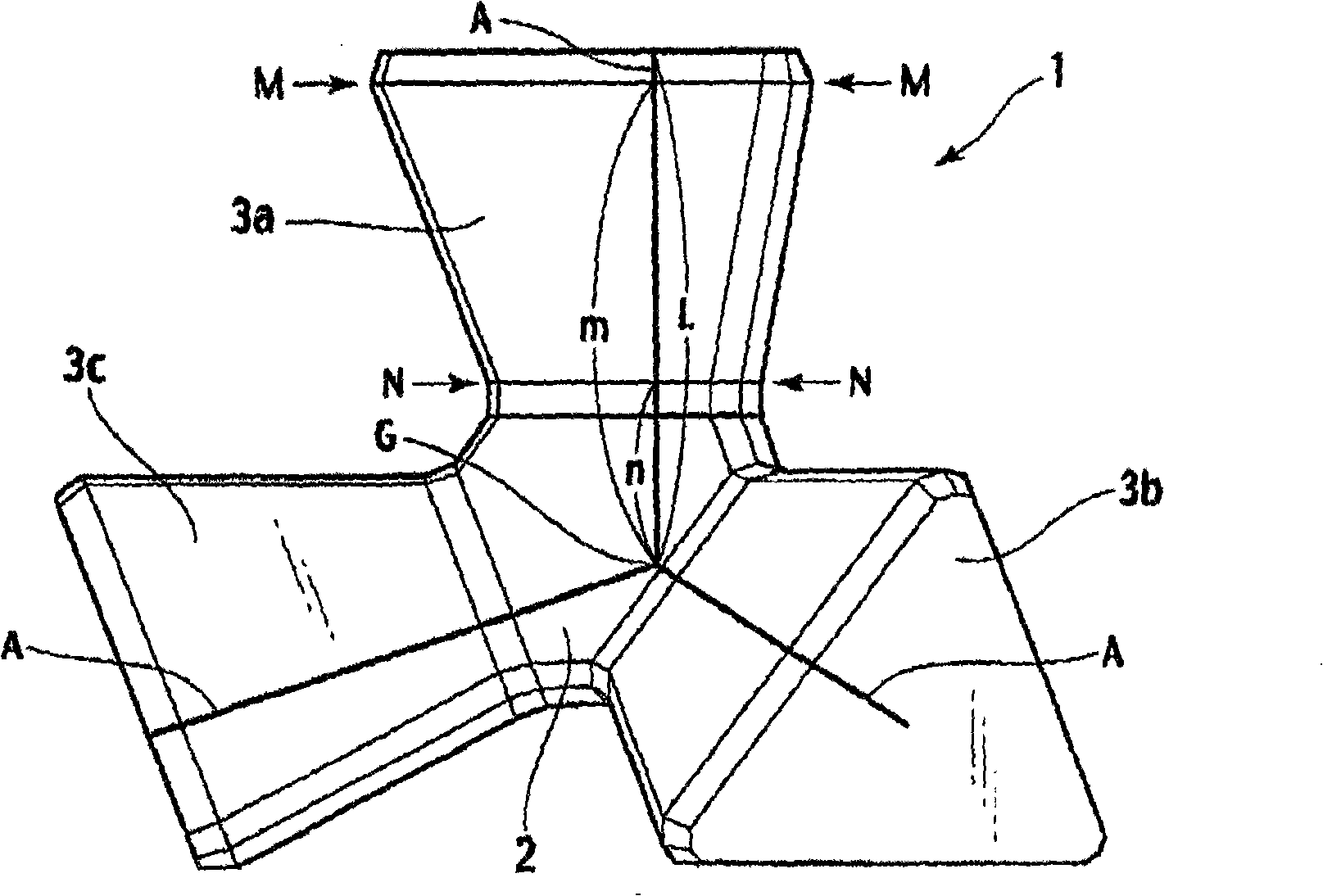

[0014] Hereinafter, embodiments of the present invention will be described with reference to the drawings. Such as figure 1 As shown, the wave breaking block 1 is composed of a central base 2 and four legs 3 (3a-3d) protruding radially outward from the base 2. in addition, figure 2 The three thick lines A in the figure are the axes of the respective leg portions 3a to 3c. And the point G is the center of gravity of the wave breaking block 1 .

[0015] All four leg parts 3a-3d have the same shape and the same size. Both the shape of the front end surface of each leg part 3a-3d, and the cross-sectional shape orthogonal to the axis A are substantially equilateral triangles. As shown in the figure, in each of the leg portions 3a to 3d, the thickest part M (the part where the area of the cross section perpendicular to the axis A (the area inside the cross-sectional contour line) is the largest) is located at the thinnest part N (the area of the cross section perpendicular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com