Method for detecting DC motor rotor location of no location sensor brushless

A technology of brush DC motor and rotor position, which is applied in the direction of electronically commutated motor control, electrical components, electronic commutator, etc., can solve the problems of detecting inductance and increasing the difficulty of realization, etc., and achieves the effect of easy realization and simple implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

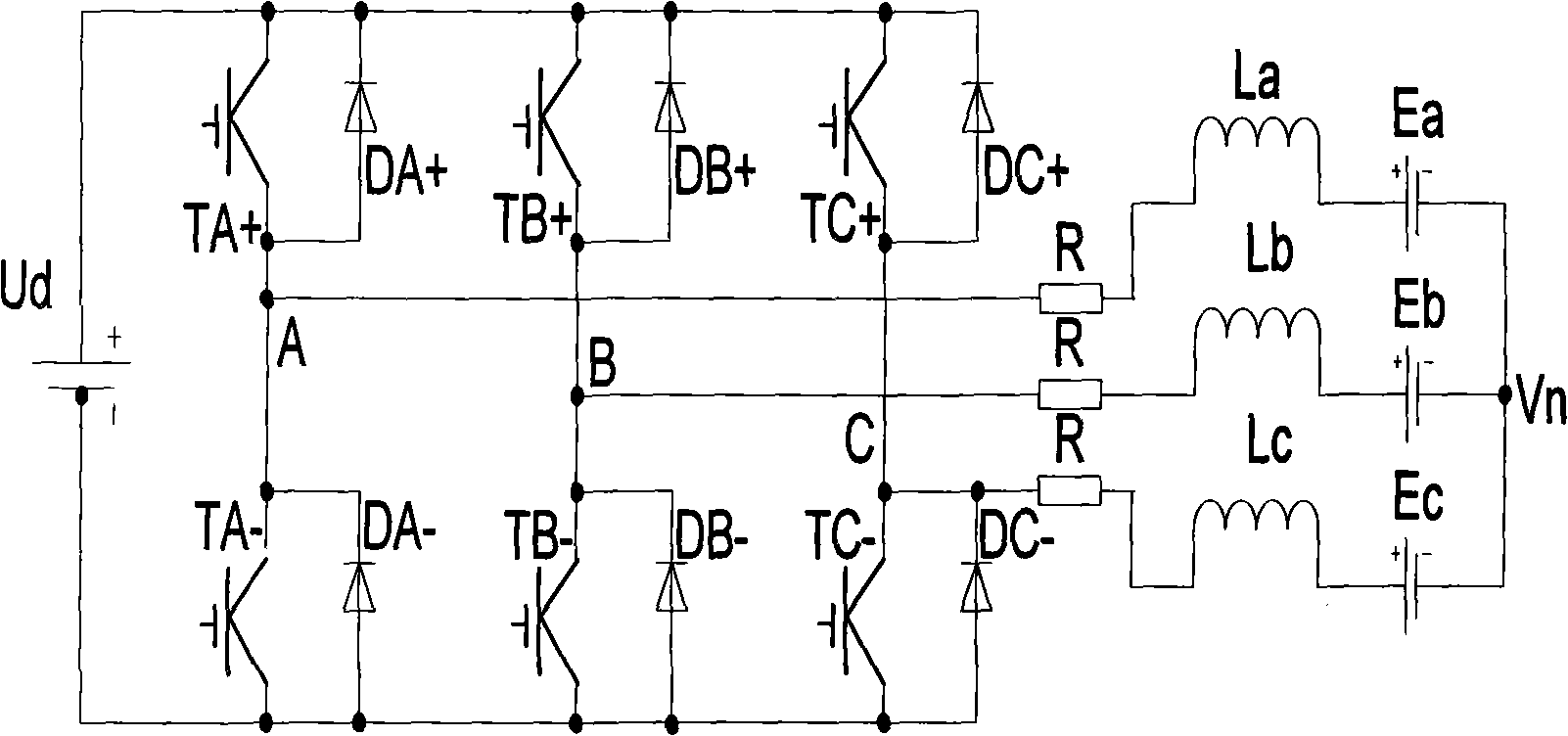

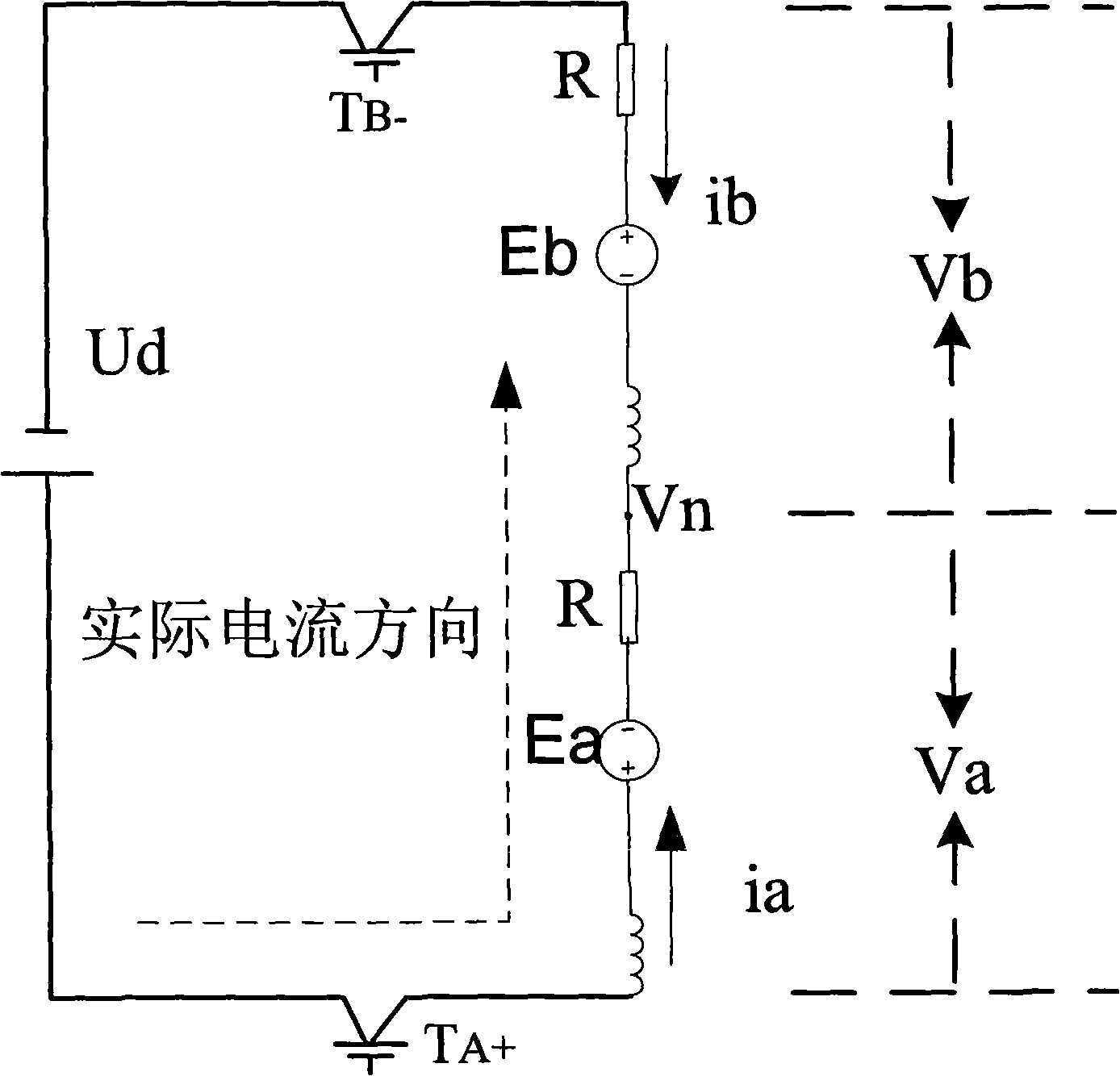

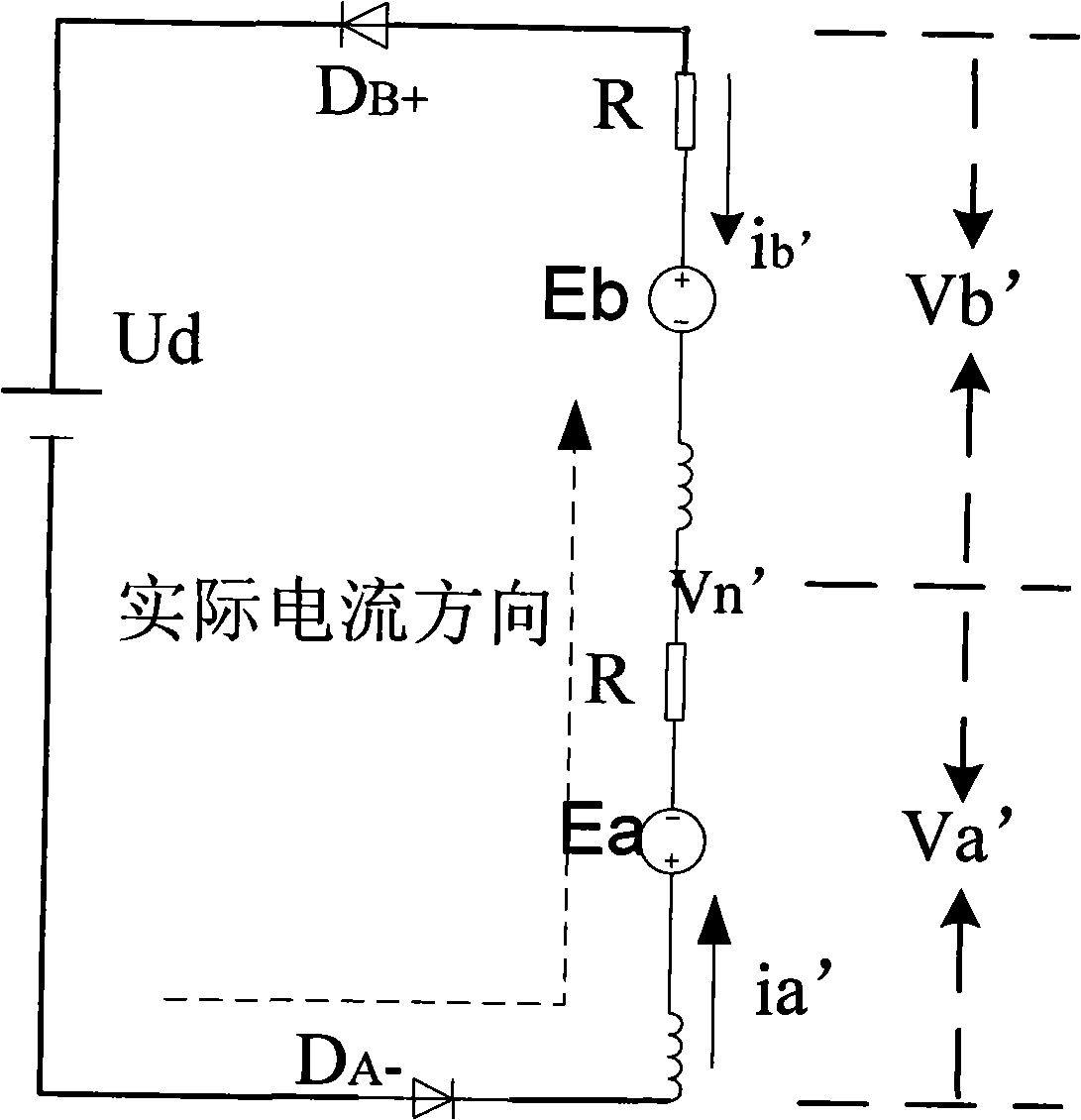

[0023] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing and by specific embodiment:

[0024] In the salient pole permanent magnet brushless DC motor, the difference of d-axis and q-axis reluctance leads to the change of winding inductance. The q-axis inductance is not equal to the d-axis inductance, because the magnetic flux passing through the d-axis magnetic circuit passes through two permanent magnets, while the q-axis magnetic flux only passes through the air gap and the stator and rotor cores, not through the permanent magnets, so q The ratio of the shaft inductance to the d-axis inductance is much larger than that of the hidden pole motor, and the change of the inductance can be used as a function of the position to obtain the position information of the rotor. The inductance of each phase winding of a salient pole motor varies with the position of the rotor. In a two-pole motor, the inductances of stator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com