Polymer dispersed LCD bistable film and method of manufacture

A technology for dispersing liquid crystals and manufacturing methods, which is applied in optics, instruments, nonlinear optics, etc., and can solve problems such as high driving voltage and poor contrast.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

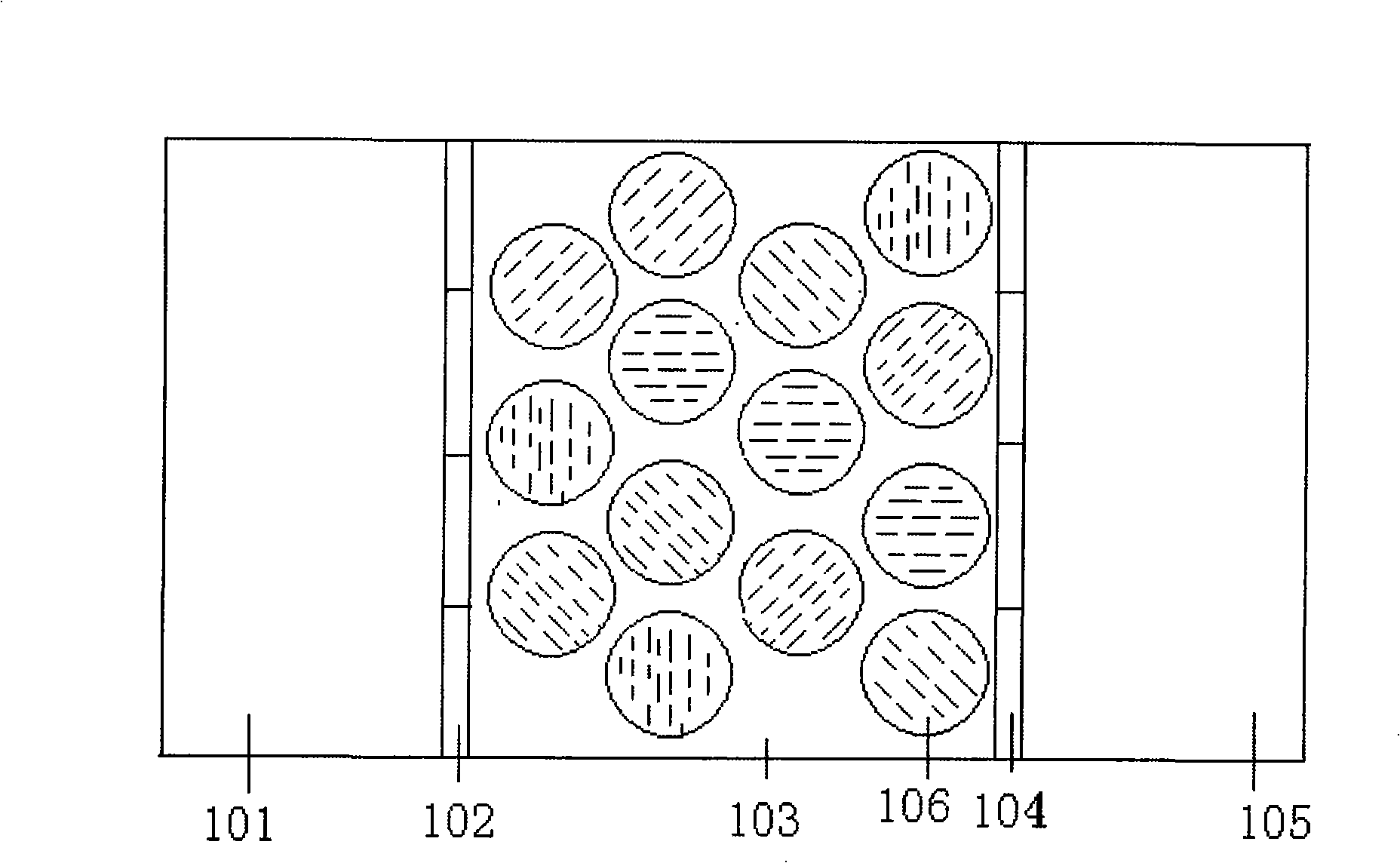

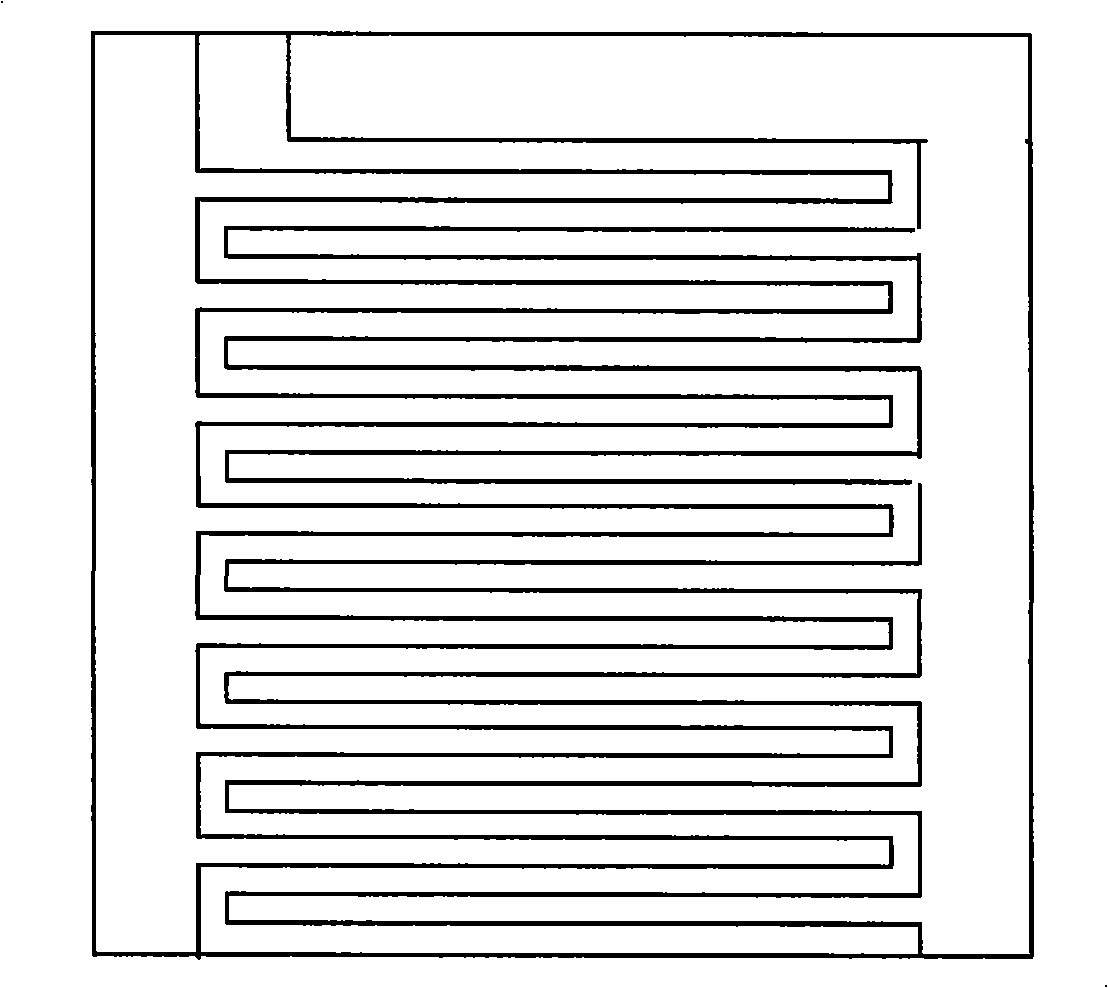

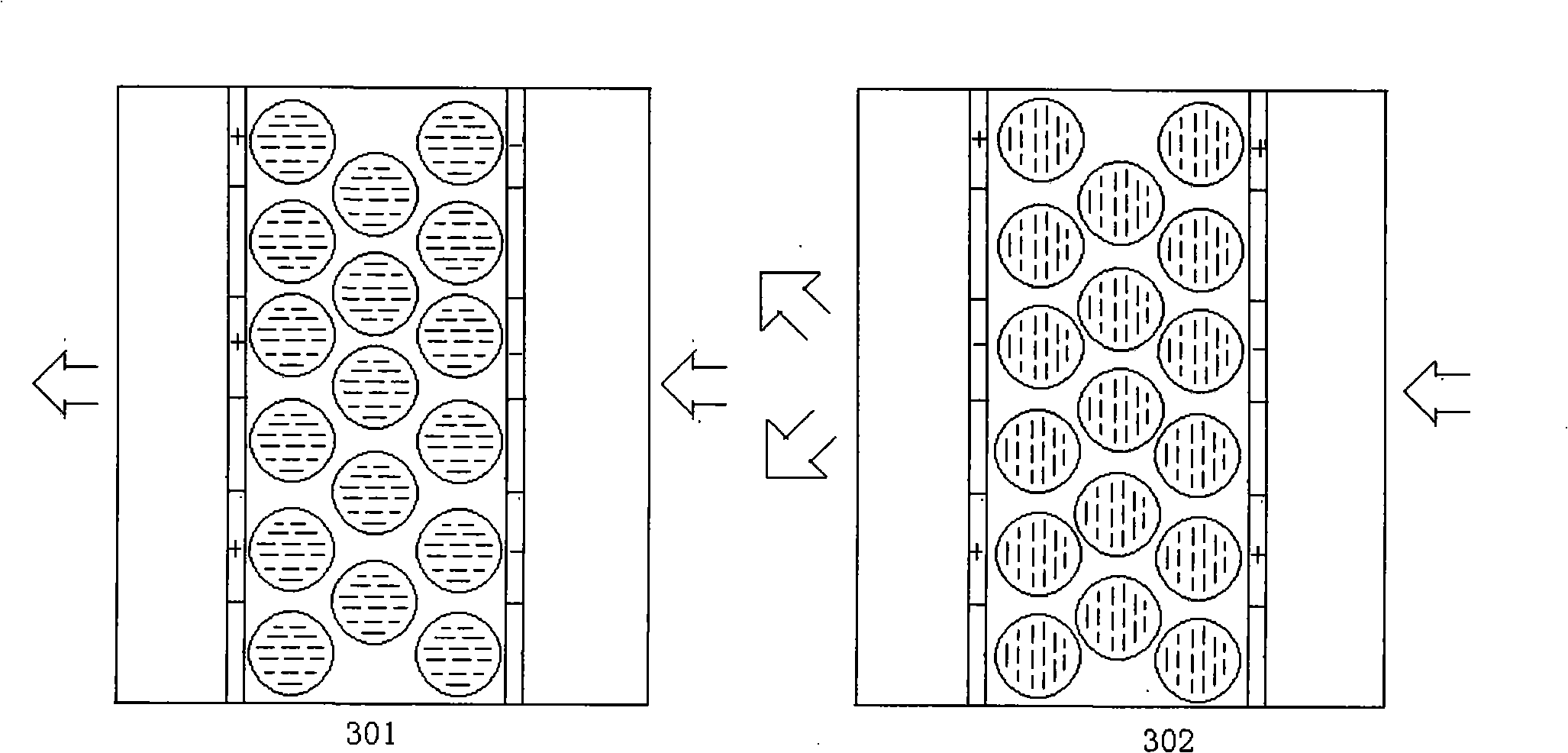

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. Polymer dispersed liquid crystal bistable composite film is produced in the ultra-purification workshop. The production equipment mainly includes ultra-pure deionized water cleaning machine, photoresist coating machine, ultraviolet exposure machine, developing and fixing pool, acid etching pool, prepolymer Mixing mixer with liquid crystal, prepolymer coating machine, pressing machine, platform sealing UV curing machine, slicer, etc.

[0029] The high active prepolymer used in the present invention is the prepolymer of the polyurethane acrylate system that has added surfactant Tween and lecithin (the mass ratio of prepolymer and surfactant is 100: 1-4, Tween: lecithin is 1:1). The kind of diluting monomer used in the present invention has isobornyl acrylate (IBOA), 1,6 hexanediol diacrylate (HDDA), trimethylolpropane triacrylate (TMPTA) and 2-(2-ethoxy E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com