Binding fastener

The technology of a fastener and a parent part is applied in the field of binding fasteners, which can solve the problems of difficulty in adjusting the height and angle of the fixed object, occupying the space used by pedestrians and non-motor vehicles, and affecting the safety of pedestrians and non-motor vehicles crossing the street. To achieve the effect of saving installation time and procedures, reducing installation costs, and reliable function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the present invention is described in detail:

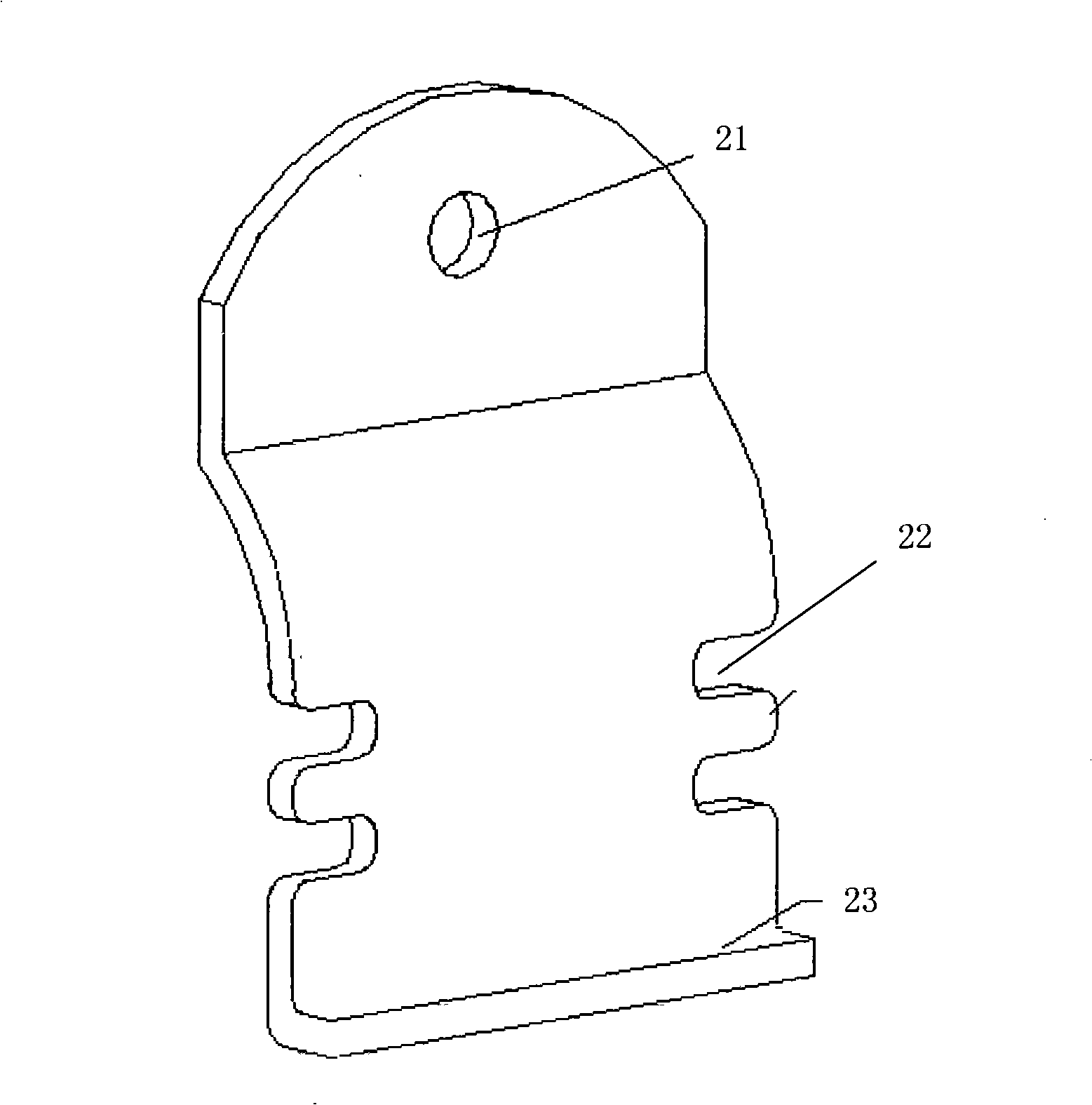

[0018] Refer to the drawings in the manual Figure 1 to Figure 3 , the binding fastener of the present invention includes a female part 1, the lower end of the female part 1 is a two separate bases 11 for connecting the first part 10, and the middle part of the female part 1 extends upwards from the two separate bases 11 The two extended side walls 12 have a junction 13 at the upper end of the parent part 1 for connecting the second component 10 ′, and the two ends of the junction 13 are transitionally connected with the upper ends of the two side walls 12 . Two clips 2 are detachably connected to the part 13, and the joint part (13) of the two clips 2 and the parent part can form a fastening space 4 for fixing the second part 10'.

[0019] A longitudinal opening 131 is arranged on the joint part 13, and the longitudinal opening 131 extends downward from the joint part 13 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com