Method for processing polyurethane vehicle roof plate

A processing method and polyurethane technology, applied in chemical instruments and methods, lamination devices, lamination auxiliary operations, etc., can solve problems such as affecting product quality, low production efficiency, and difficulty in ensuring consistent overall performance, and achieve stable product quality. The effect of improving production efficiency and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

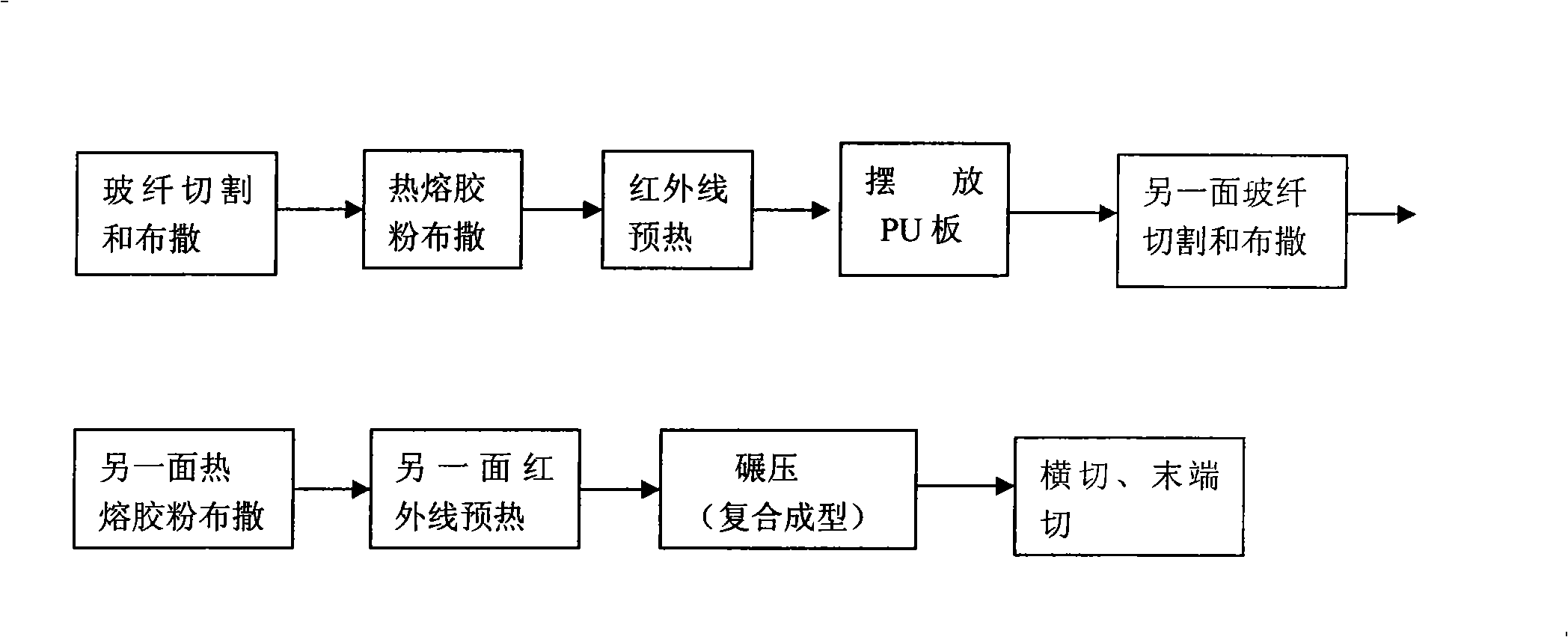

[0007] see figure 1 , the technical process of the present invention comprises:

[0008] 1. Send the glass fiber raw material to the glass fiber cutting machine through the glass fiber conveying pipe, cut the glass fiber into a specified length, and spread it evenly on the non-woven fabric. The speed of the glass fiber cutting machine is input into the computer console through calculation, so that the length and capacity of the glass fiber can meet the specified requirements. The non-woven fabric is conveyed by a conveyor belt.

[0009] 2. By controlling the speed of the powder spreader and the vibrator, evenly sprinkle the specified capacity of hot melt adhesive powder (PE powder) on the non-woven fabric and glass fiber.

[0010] 3. Use an infrared preheater to preheat the non-woven fabric, glass fiber and hot-melt adhesive powder with infrared rays. The power of the infrared preheater is 0-100KW, which can be adjusted in the range of 0-100% according to the requirements o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com