Device for holding a piston in a plant for coating pistons

A technology for fixing devices and coating equipment, which is applied in the direction of surface coating liquid devices, workpiece clamping devices, coatings, etc., and can solve the problems of complicated and laborious manufacturing of piston fixing devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Today's engines have multiple pistons made of aluminum oxide, which can be coated with iron to reduce wear on the pistons. It is usually achieved by electrolytic coating. For this purpose, a corresponding coating system comprises a plurality of coating electrolytic cells, each of which comprises a plurality of piston holders to which the pistons are fastened.

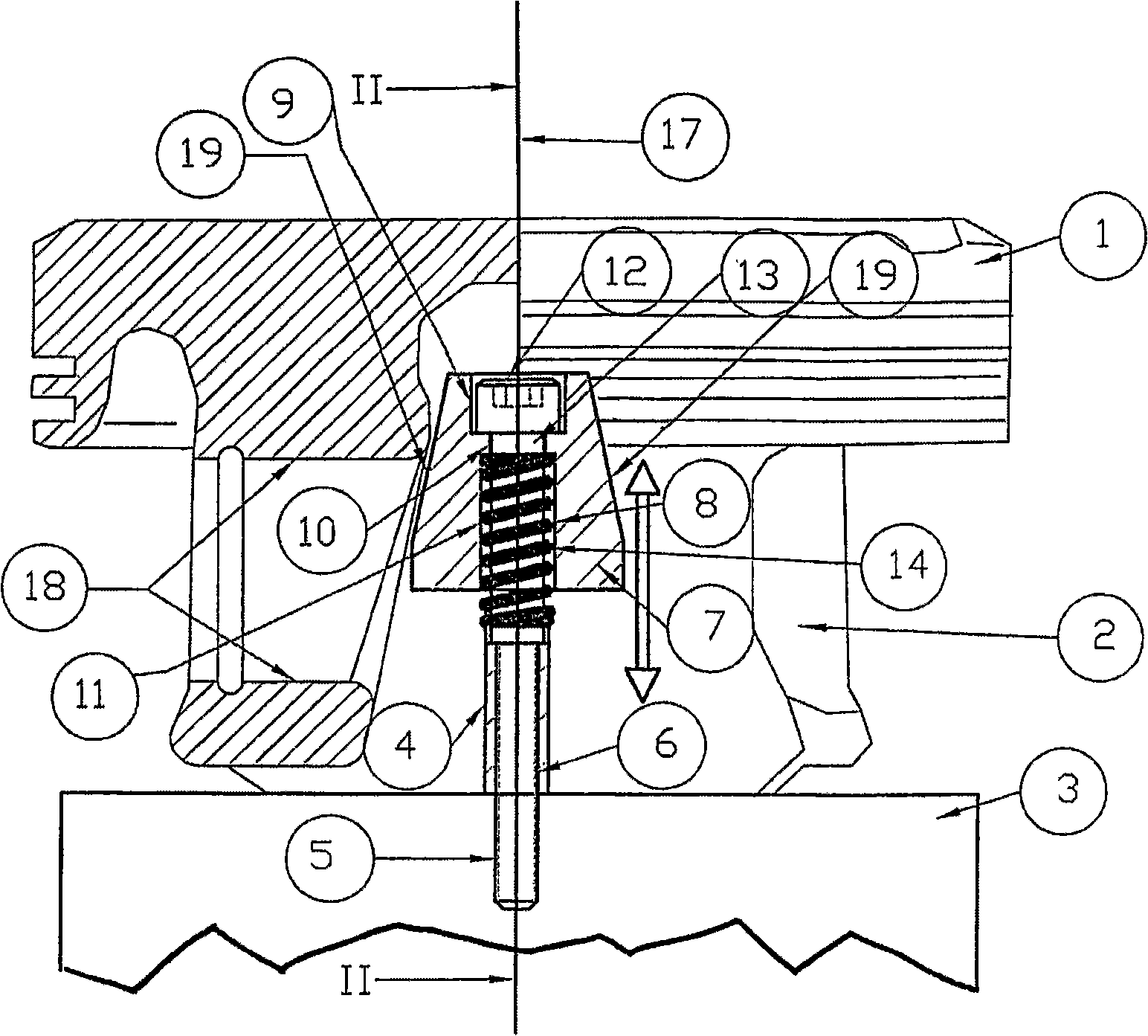

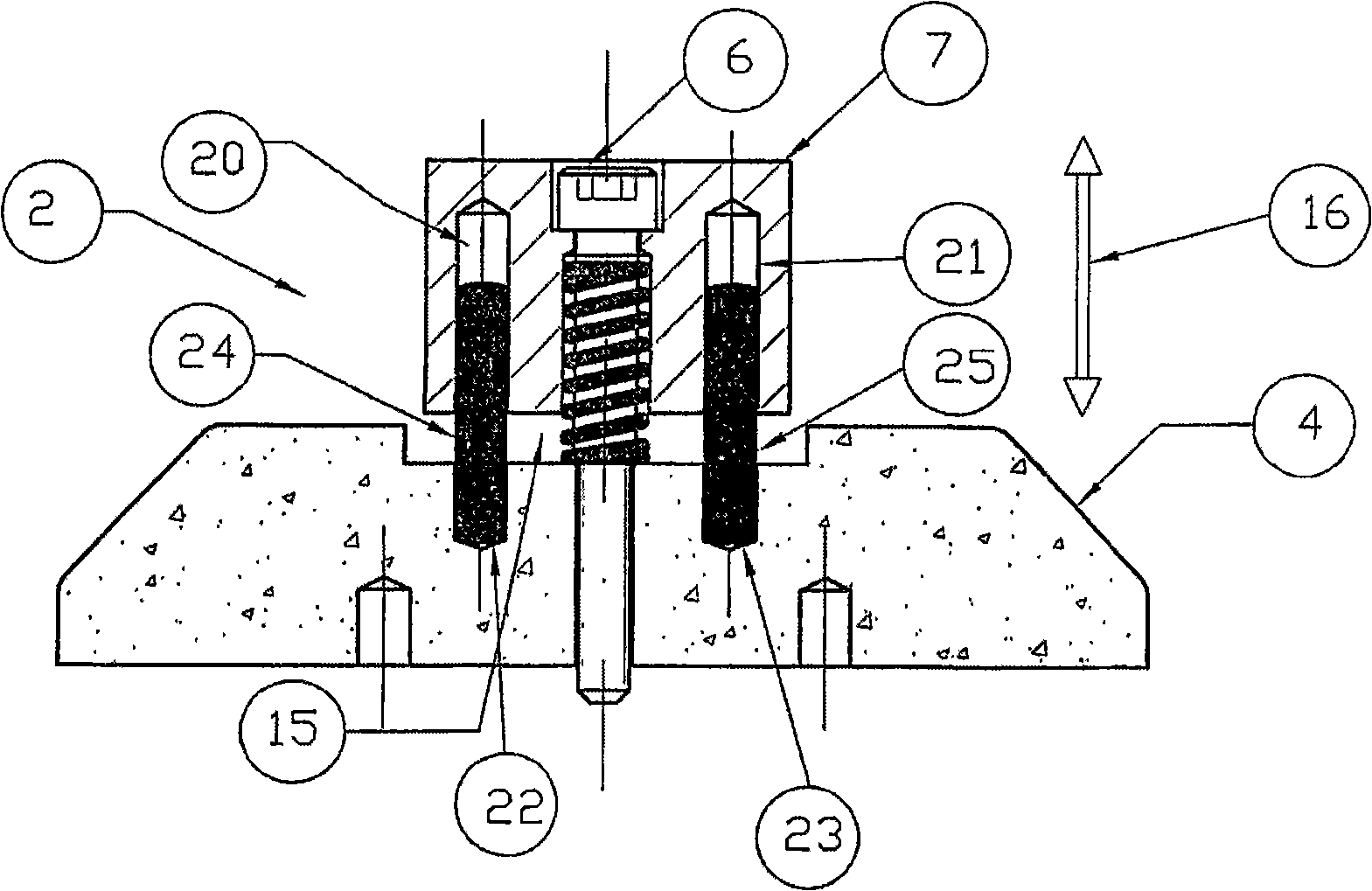

[0009] like figure 1 As shown, the fixing device 2 of the piston 1 includes a bracket 3 on which a base 4 fixed by a hexagonal screw 6 is arranged. The carrier 3 includes a threaded bore 5 with an internal thread running vertically, that is to say parallel to the axial direction 17 of the piston. A hexagonal screw 6 is screwed into this threaded hole 5 for fastening a calibration part 7 made of brass. For screwing in the screw 6 , the alignment part 7 has a through-bore 8 which is divided into three. The bore 8 consists of an upper part 9, a middle part 10 and a lower part 11 close to the bottom end of the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com