Treatment method for destabilization three-phase separation of emulsified water-in-oil type oily wastewater

A water-in-oil type and three-phase separation technology, which is applied in the field of oil and gas drilling, can solve the difficulties of resource utilization and environmental protection disposal of three-phase separation and phase separation, which will produce a large amount of toxic and harmful polluting gases and dust, and resources are not well obtained Resource utilization and other issues, to achieve the effect of ingenious selection of components, efficient destabilization treatment, and increased speed of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

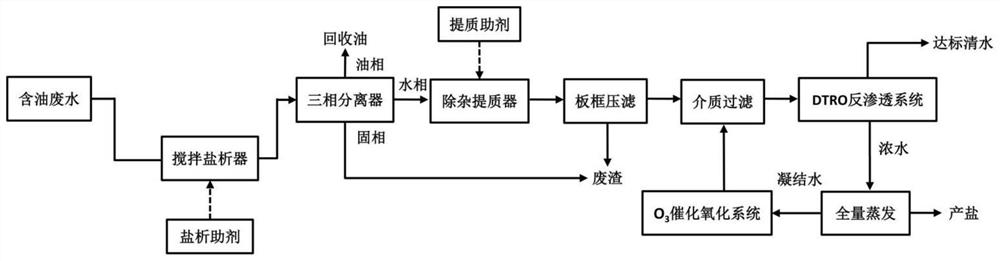

[0035] Oily wastewater is divided into emulsified oil-in-water type and water-in-oil type according to water quality conditions, and the present invention provides a treatment method for destabilizing three-phase separation of oily wastewater, which is aimed at the recovery of emulsified water-in-oil type oily wastewater processing, such as figure 1 Shown, main technological process of the present invention is as follows:

[0036] (1) Use the salting-out process to destabilize the emulsified water-in-oil oily wastewater, wherein the salting-out additive used is composed of CaCl 2 and FeCl 3 ·7H 2 O composition, the salting-out aid is by weight, in every ton of oily wastewater, CaCl 2 , FeCl 3 ·7H 2 The consumption ratio of O is 1~15% and 1~20%;

[0037] (2) Pump the destabilized oily wastewater into the three-phase separator, the separation speed is 3000-3500rpm, and the separation time is 15-20min, so as to realize the three-phase separation of oil phase, water phase an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| osmotic pressure | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com