Method for extracting chitosan by employing flies

A technology for chitosan and flies, which is applied in the field of chitosan extraction, can solve the problems of difficulty in large-scale production, industrialized production, impact on product development, large gap between supply and demand, etc., and achieves high economic value, increased production scale, and increased output. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

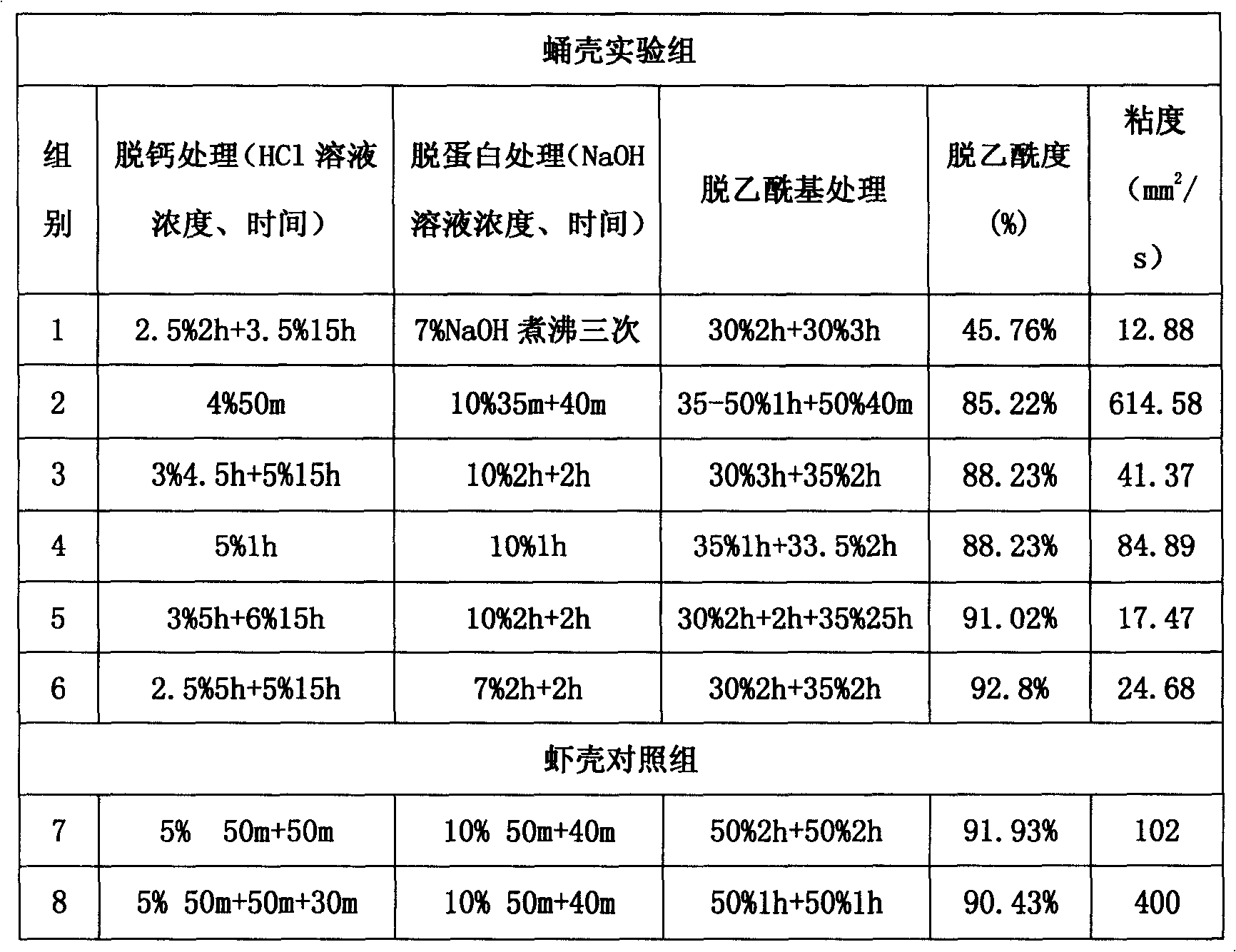

[0031] Raw material acquisition, acid-base treatment of fly pupal shells. After decalcification treatment, deproteinization treatment, and deacetylation treatment, the obtained substance is filtered, washed to neutrality, collected and dried, which is the finished product of chitosan.

[0032] Embodiments of the invention:

[0033] (1) Methods and steps

[0034] 1. Acquisition of raw materials

[0035] (1) Hatching of eggs:

[0036] The fly eggs were hatched in a light incubator, the temperature was controlled at 25°C, and the relative humidity was 70%-80%. After 1 to 2 days, the eggs basically hatch into larvae.

[0037] (2) Growth and development of fly maggots:

[0038] The larvae of flies are commonly known as fly maggots, and they can mature and pupate after 4 to 6 days in a dark place indoors where the temperature is 25°C and the ambient hum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com