Apparatus for calibrating gas instrument

An instrument verification and gas technology, which is applied in the field of equipment for the verification of gas flow detection instruments, can solve the problems of reduced vacuum pumping ability, environmental noise pollution, vacuum pump burnout, etc., and achieves the effect of reducing additional errors and avoiding noise pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

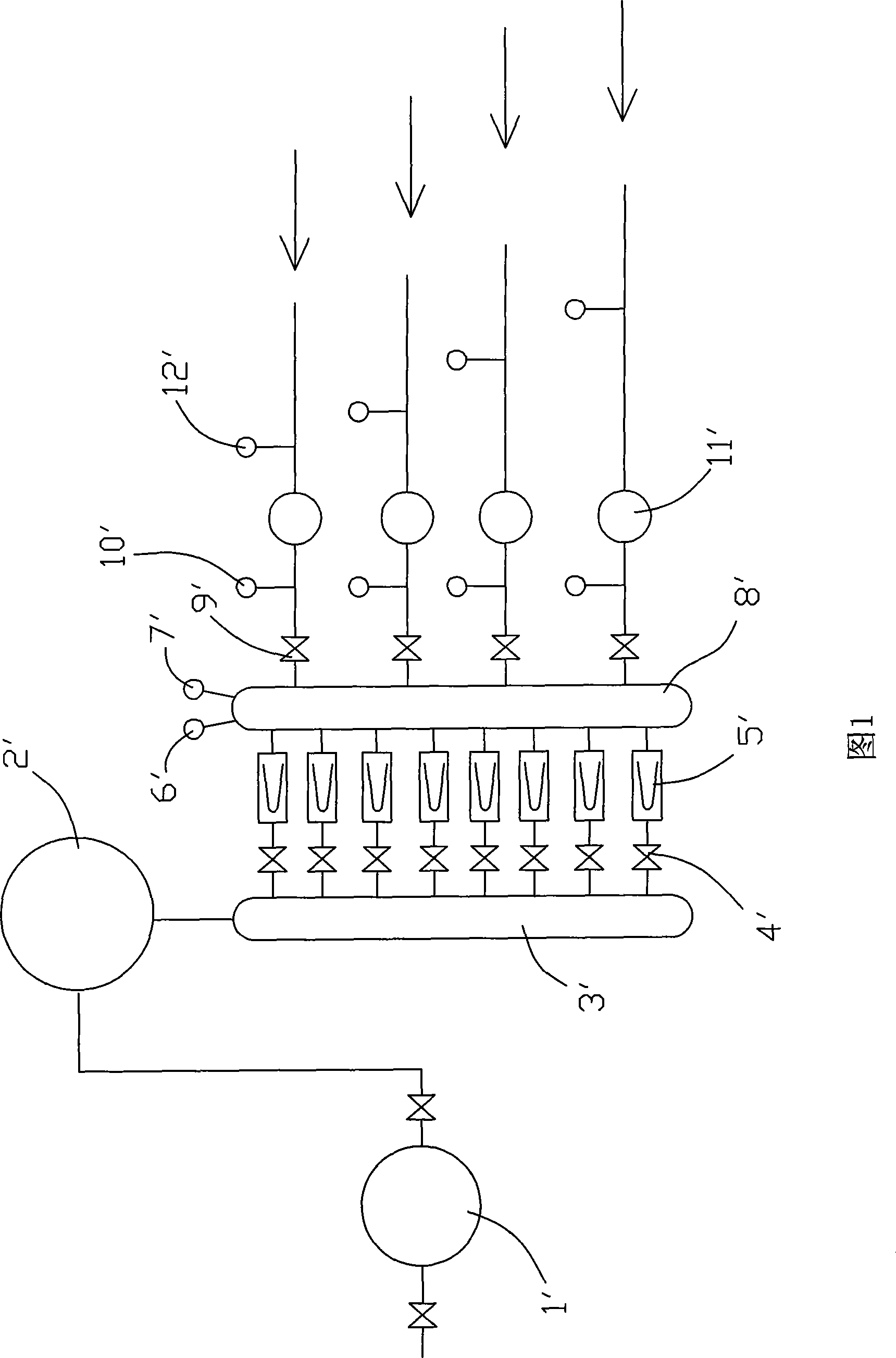

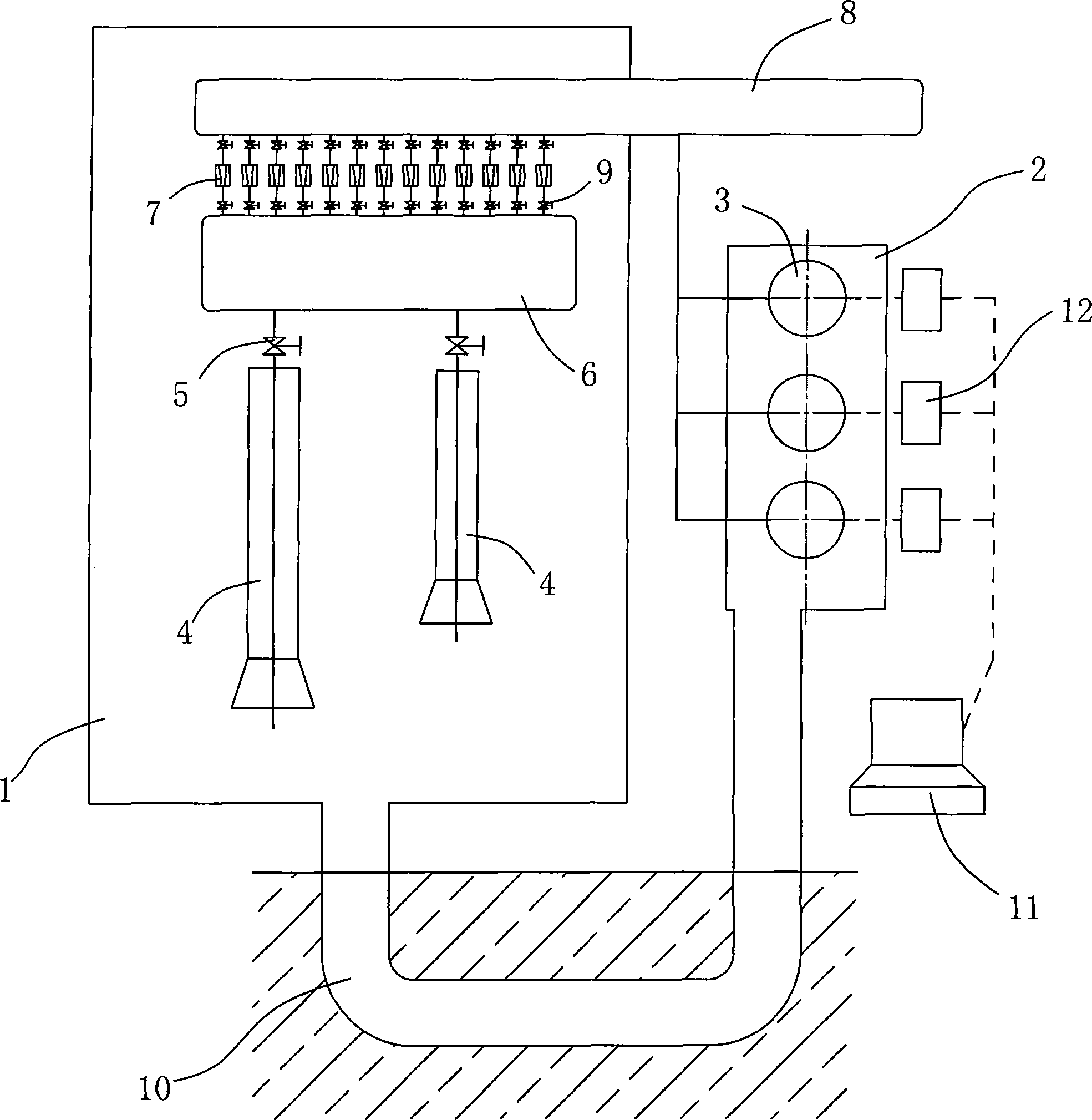

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0028] like figure 2 As shown, the gas instrument verification device of the present invention includes a sealable verification chamber 1 and a sealable soundproof chamber 2, and three Roots vacuum pumps 3 are arranged in the soundproof chamber 2, and two The verification station 4 where the flowmeter to be tested is placed, the verification station 4 is sequentially connected with a flow regulating valve 5, a stagnation container 6, a row of sonic nozzles 7, and a negative pressure pipeline 8. Both ends of the sonic nozzle 7 are equipped with There is an on-off valve 9, and the flow regulating valve 5, the stagnation container 6, the sonic nozzle 7, and the part of the negative pressure pipeline 8 corresponding to the sonic nozzle 7 are all arranged in the test chamber 1, and the negative pressure pipeline The rest of 8 protrudes out of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com