Rotation control device and working machine therewith

A technology for rotating control devices and operating machinery, applied in control systems, motor controls, electric controllers, etc., can solve the problems of not being able to control smoothly, not reflecting the working state, and discontinuous changes in torque, so as to suppress the occurrence of shocks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings.

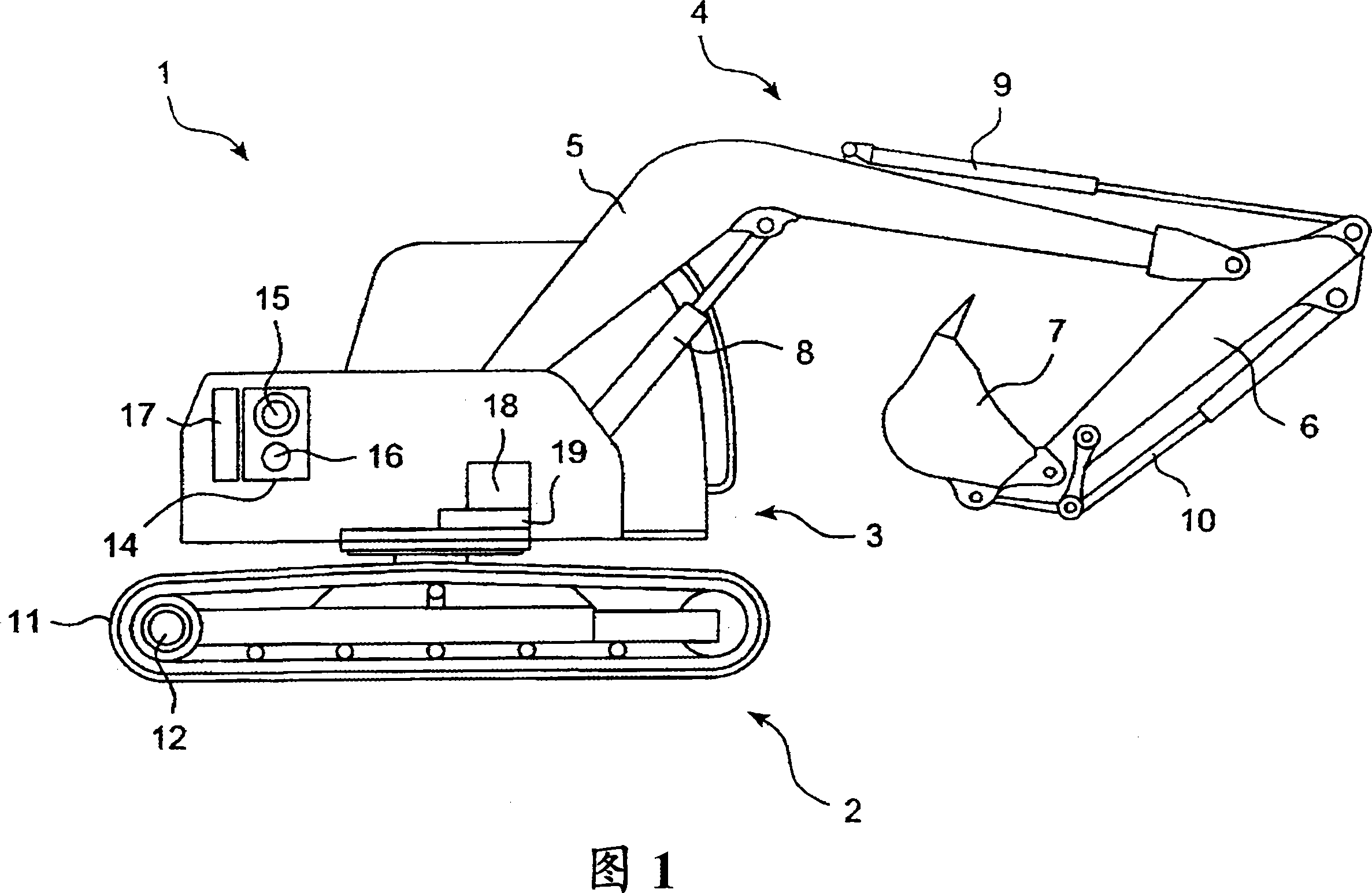

[0050] Fig. 1 shows a side view showing the overall structure of an excavator according to an embodiment of the present invention. Fig. 2 is a block diagram showing the structure of the drive and control system of the shovel of Fig. 1.

[0051] 1 and 2, an excavator 1 as an example of a working machine is provided with a crawler-type lower moving body 2 (main body), and an upper rotating body 3 rotatably mounted on the lower moving body 2 (main body) And a work attachment 4 mounted on the front part of the upper rotating body 3.

[0052] The work attachment 4 is provided with a boom 5 mounted on the upper rotating body 3 so as to be raised and lowered, a rocker arm 6 connected to the front end of the boom 5, a bucket 7 connected to the front end of the rocker arm 6, and The upper rotating body 3 drives the boom cylinder 8 of the boom 5, the rocker arm cylinder 9 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com