Sedimentation support for bridge

A technology of bearings and bridges, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of increased maintenance costs, many supporting machines, and long operating cycles, achieving significant economic and social benefits, and timely road surface smoothness indicators , the effect of simple disposal method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

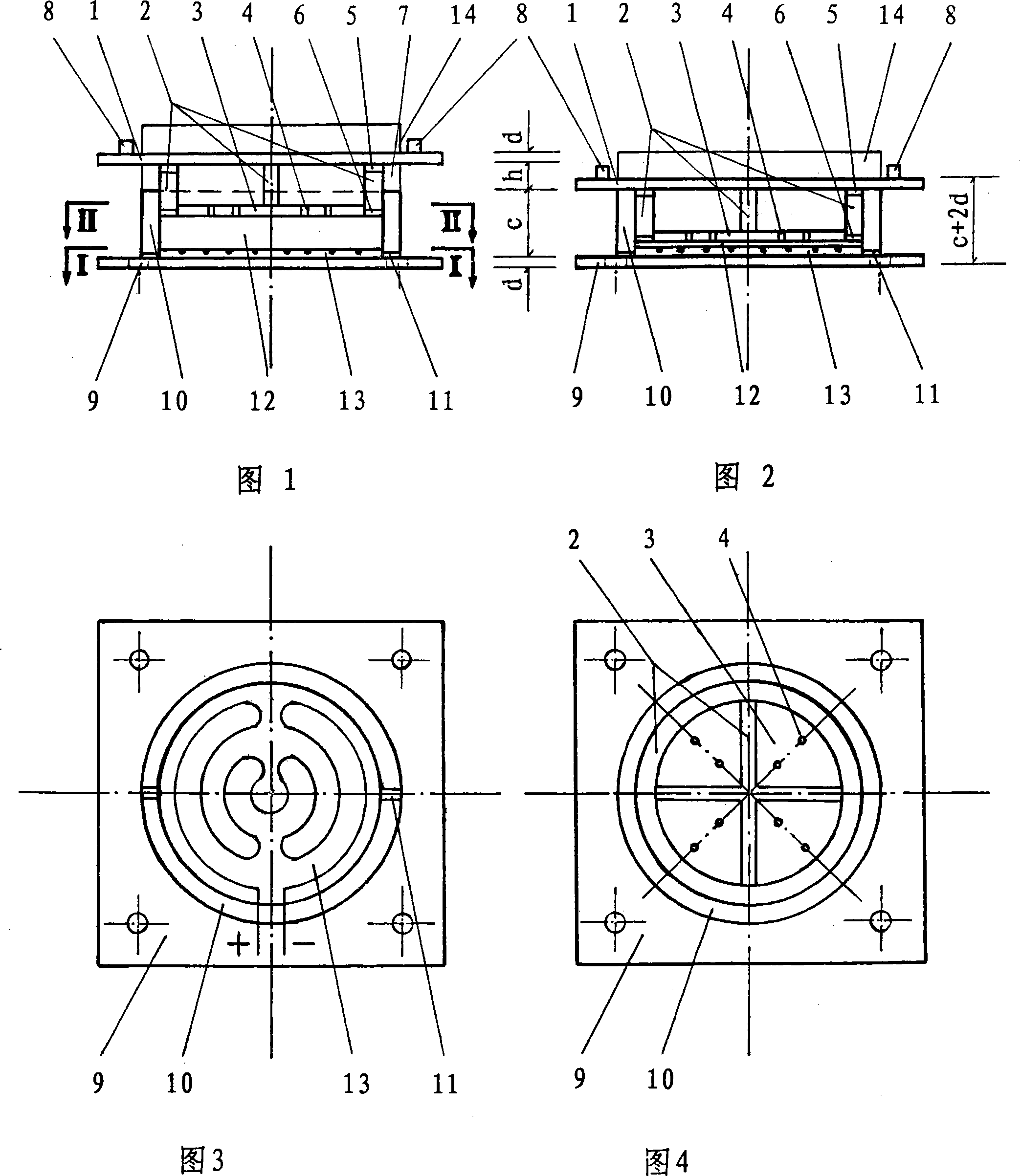

[0025] Accompanying drawing is a kind of specific embodiment of the present invention.

[0026] Bridge settlement support of the present invention comprises finished support 14 and is positioned at the bottom of finished support 14 and is positioned at the bottom of finished support and replaces the lower settlement compression device of bearing pad stone, and this device comprises upper settlement body and lower bottom basin; Upper settlement body consists of roof 1, inner The support plate 2 and the middle bearing plate 3 are composed of the top plate in the horizontal direction. Two side limit blocks 8 are arranged on the left and right sides above the top plate to position and protect the finished bearing. The middle bearing plate is fixed under the top plate through the inner support plate and The top plates are parallel, and there are four cavities between the two parallel plates. The middle support plate is circular and has 8 rheological channels 4. The inner support pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com