Yarn nozzle telescopic oscillating control mechanism for applique shuttle box

A telescopic control and yarn feeder technology, which is applied in textiles and papermaking, weft knitting, knitting, etc., can solve the problems of inconvenient installation of the return pressure spring, complex structure of the yarn feeder assembly, and increased production costs, etc., and achieves simple structure, Easy installation and debugging, not easy to distort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with embodiment.

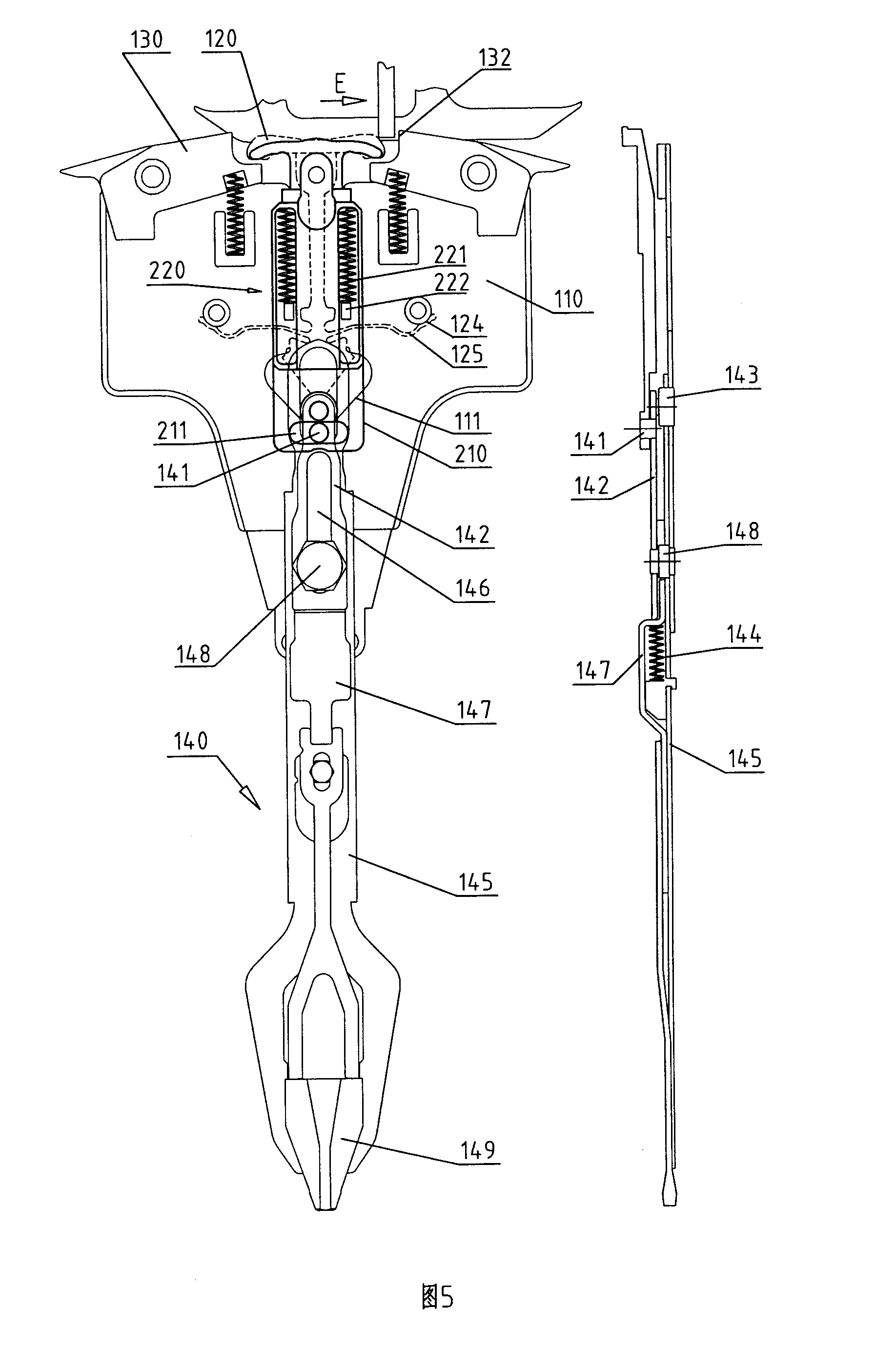

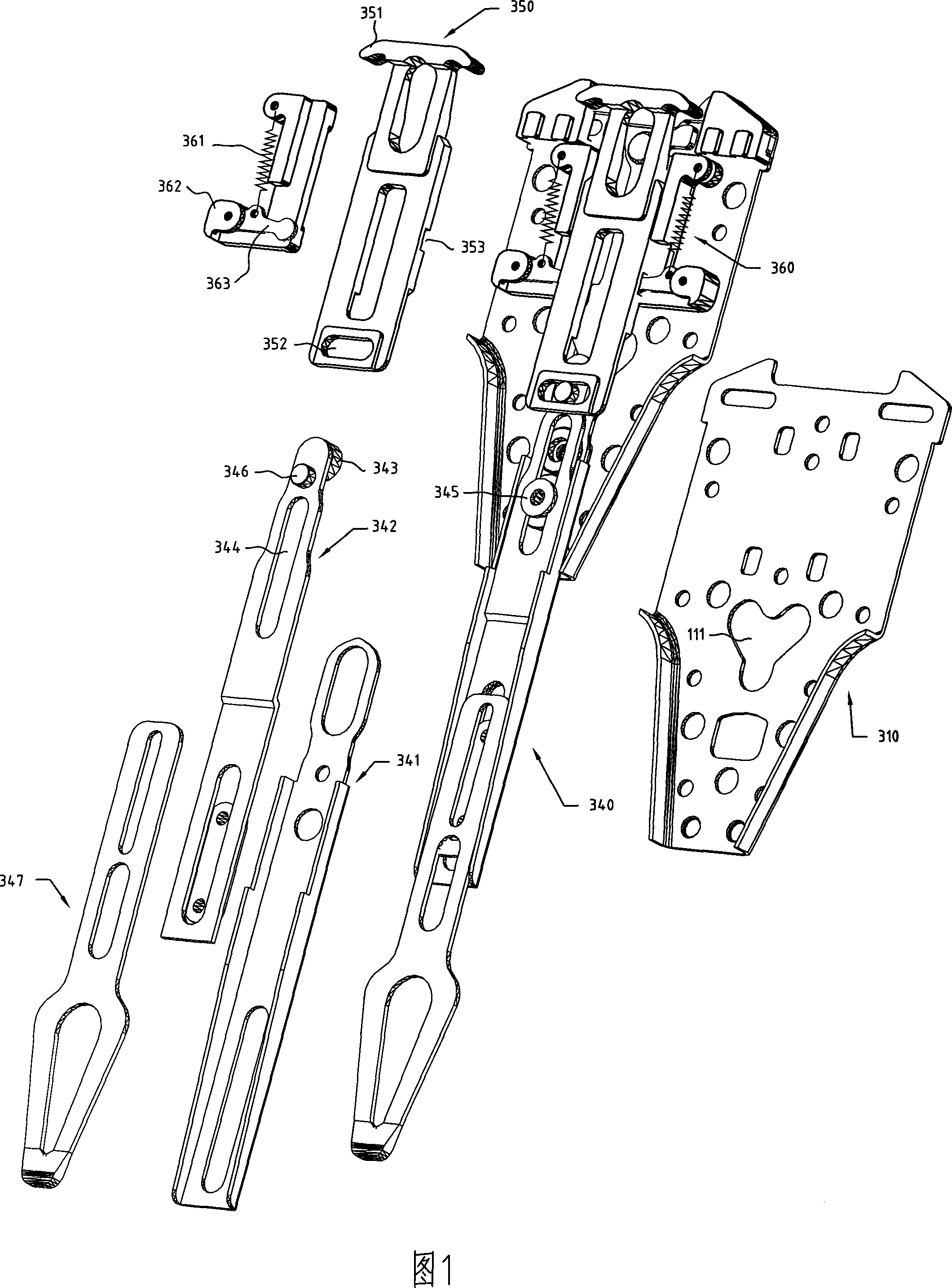

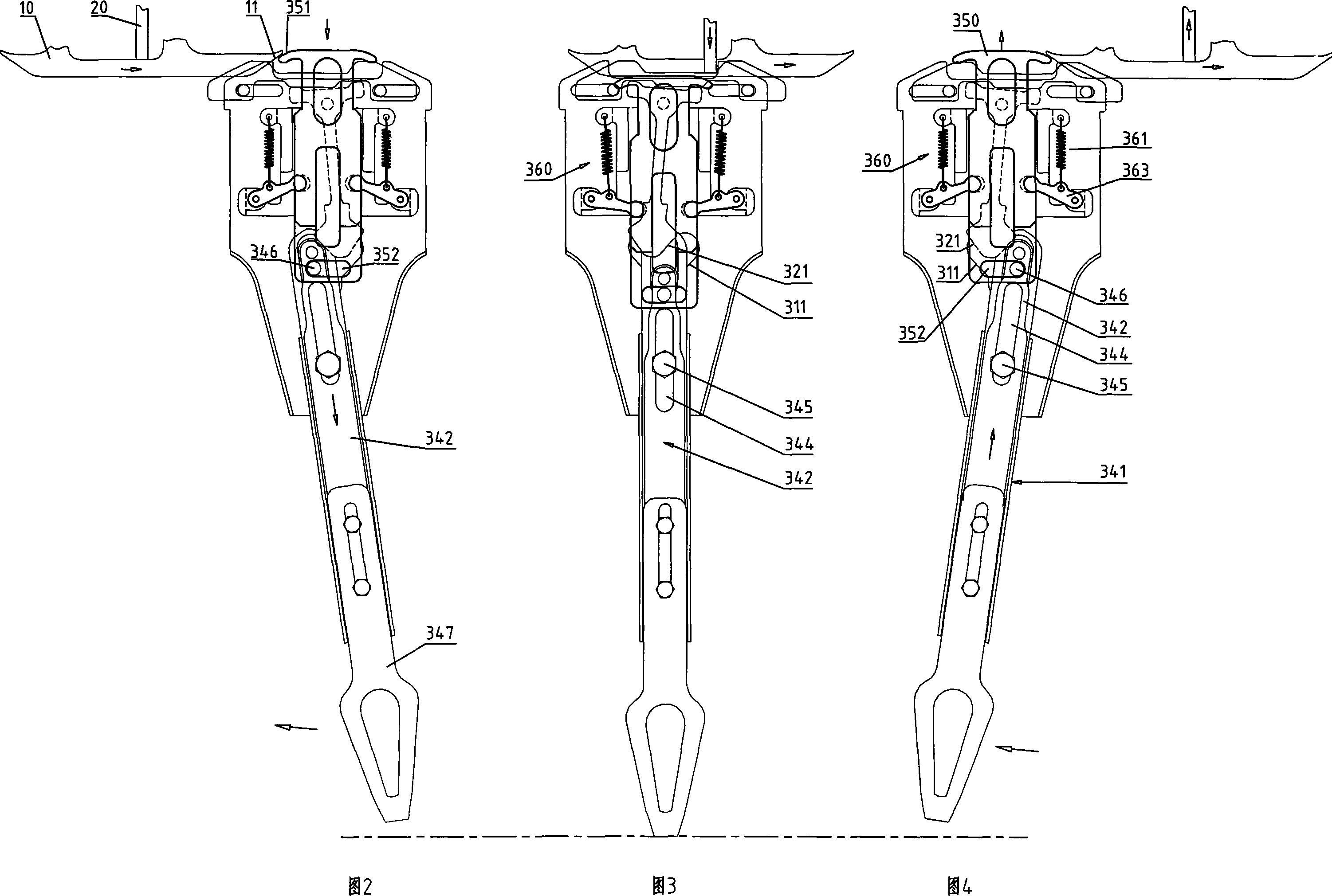

[0019] 1 and 2, the drive plate return assembly 360 composed of spring seat 362, return lever 363 and return tension spring 361 is installed on the symmetrical two sides of the upper drive plate 350 of the bottom plate 310, and one end of the return lever 363 It is hinged on the spring seat 362 (or the bottom plate 310), and its other end is embedded in the groove 353 on the rear side of the drive plate. One end of the return tension spring 361 is connected to the spring seat 362 , and the other end is connected to the return driving rod 363 . The transmission plate 350 can slide between the two spring seats 362 , and one end of the return lever 363 is embedded in the groove 353 on the rear side of the transmission plate 350 . The yarn feeder assembly 340 is connected to the bottom of the base plate 310, and the guide plate 342 on its top is provided with a slide pin 346 on its fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com