Bundling method and system for long products

A technology for rolling stock and long product, which is applied in the processing field of long product rolling stock and can solve the problems of limiting the output of rolling stock bundles and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

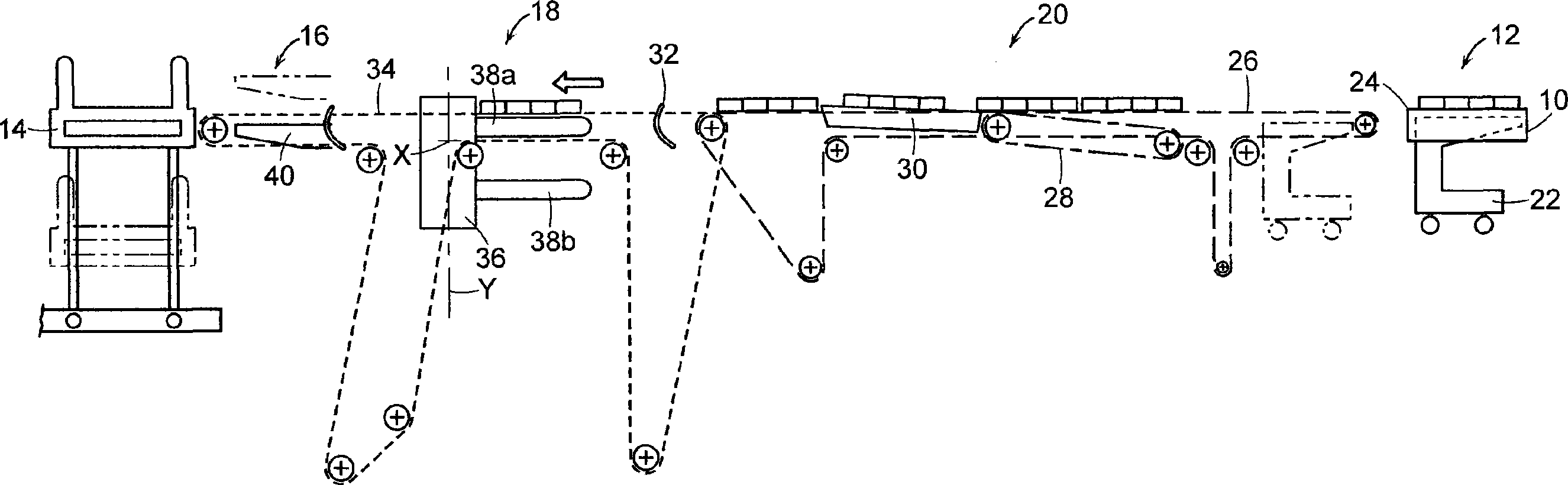

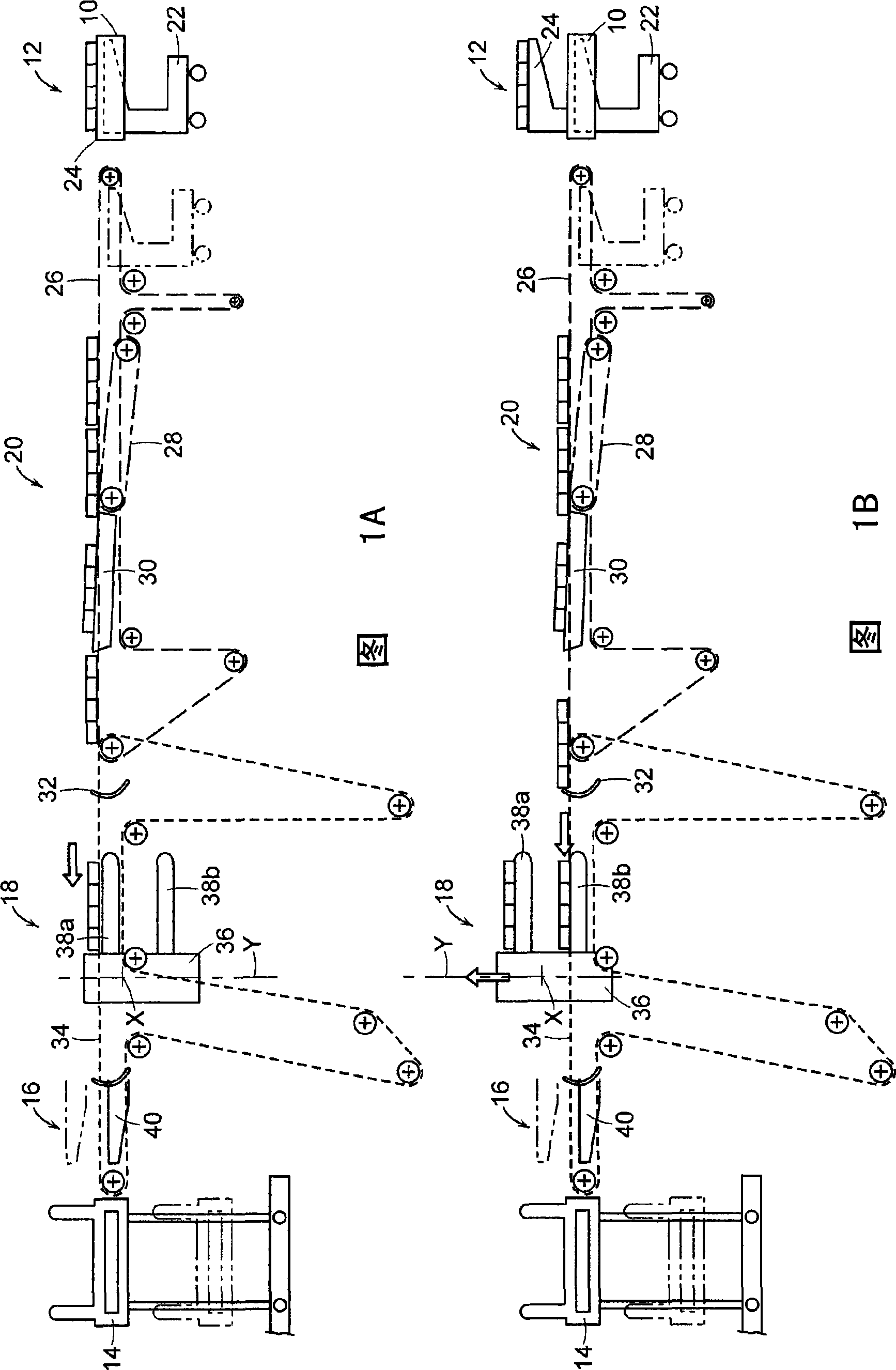

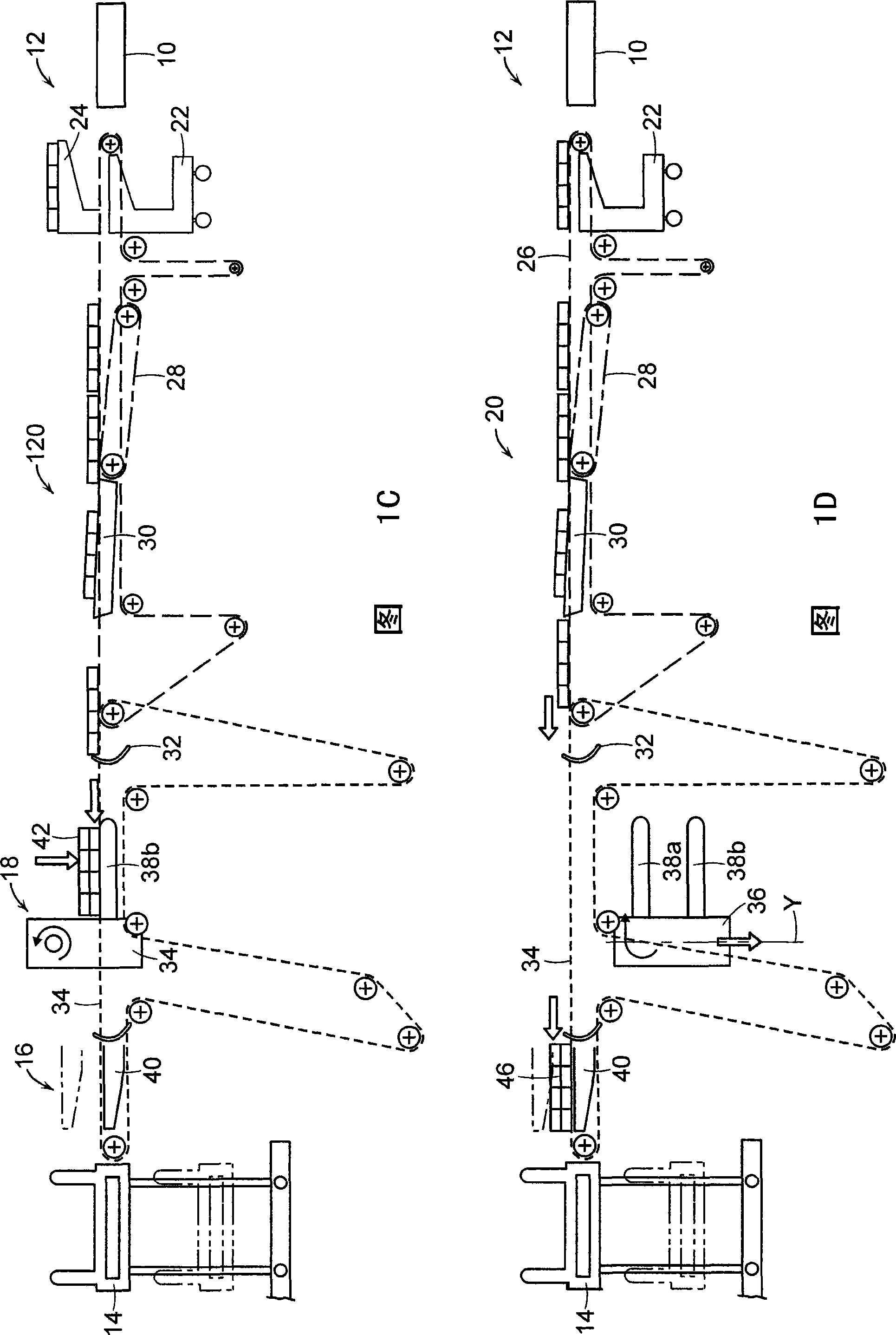

[0014] Referring initially to FIG. 1A , the stacking system according to the invention includes a roller table 10 for longitudinally conveying the long product to a receiving station 12 . The carriage 14 is spaced laterally from the receiving station 12 . The carriage is constructed and arranged in a known manner to receive and accumulate the various layers of the stock in the form of bundles.

[0015] A stacker 16 and an adjacent pre-stacker 18 are positioned between the carriage 14 and the receiving station 12 . The transport system 20 operates to advance the rolled stock laterally from the receiving station 12 to the pre-stacker 18 .

[0016] The transport system 20 comprises a transfer trolley 22 with a lifting platform whose arms 24 are vertically adjustable between the roller gaps of the roller table 10 .

[0017] As shown in FIG. 1A , the arm 24 is positioned below the long rolling stock (in this case a flat stock) on the roller table. In FIG. 1B the arms have been r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com