Connecting device for an electric motor

A connection device and motor technology, applied in the direction of motor generator connectors, electromechanical devices, conductive connections, etc., can solve the problems of space limitation, occupying space, etc., and achieve the effect of reducing the series of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

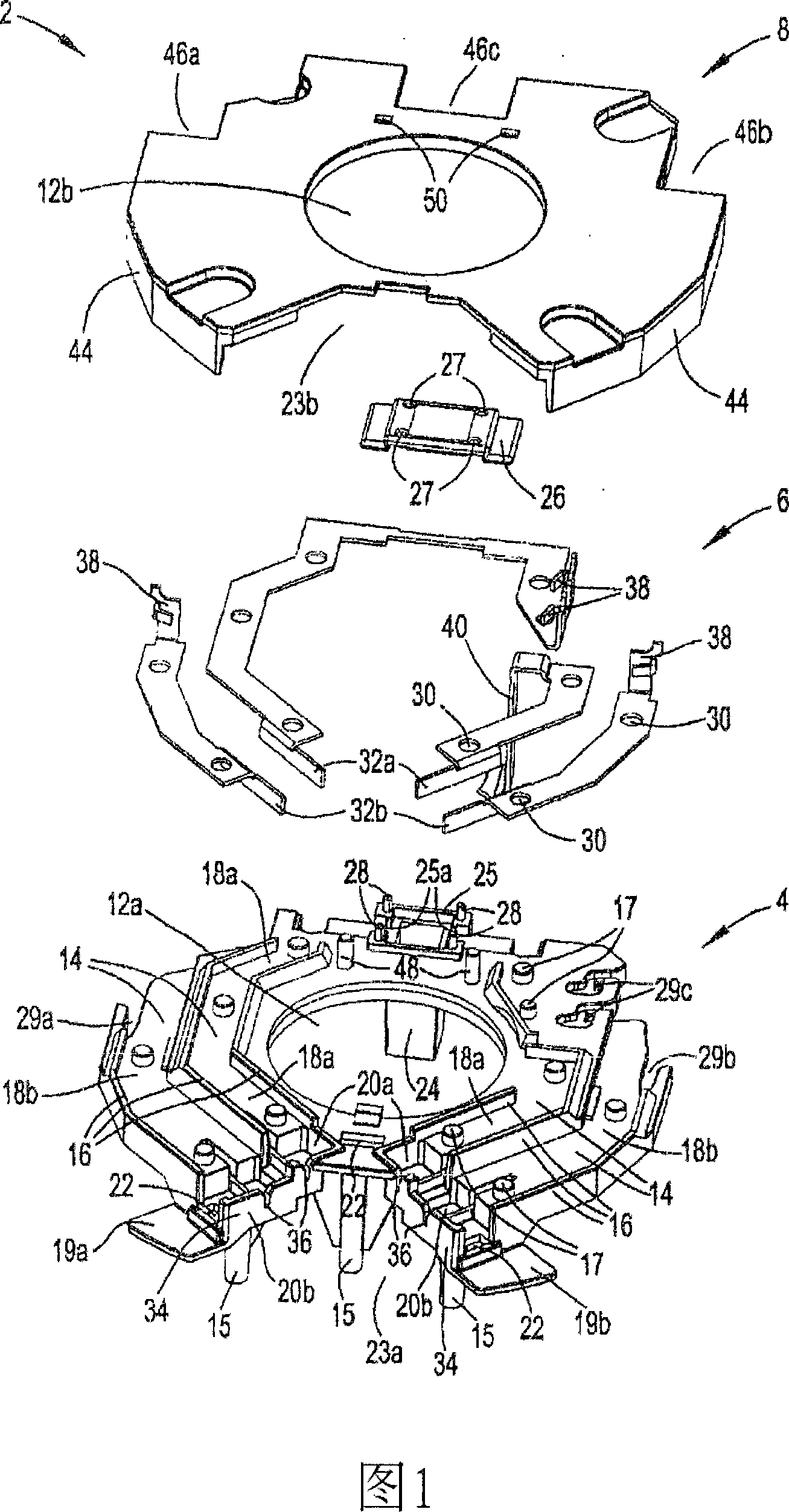

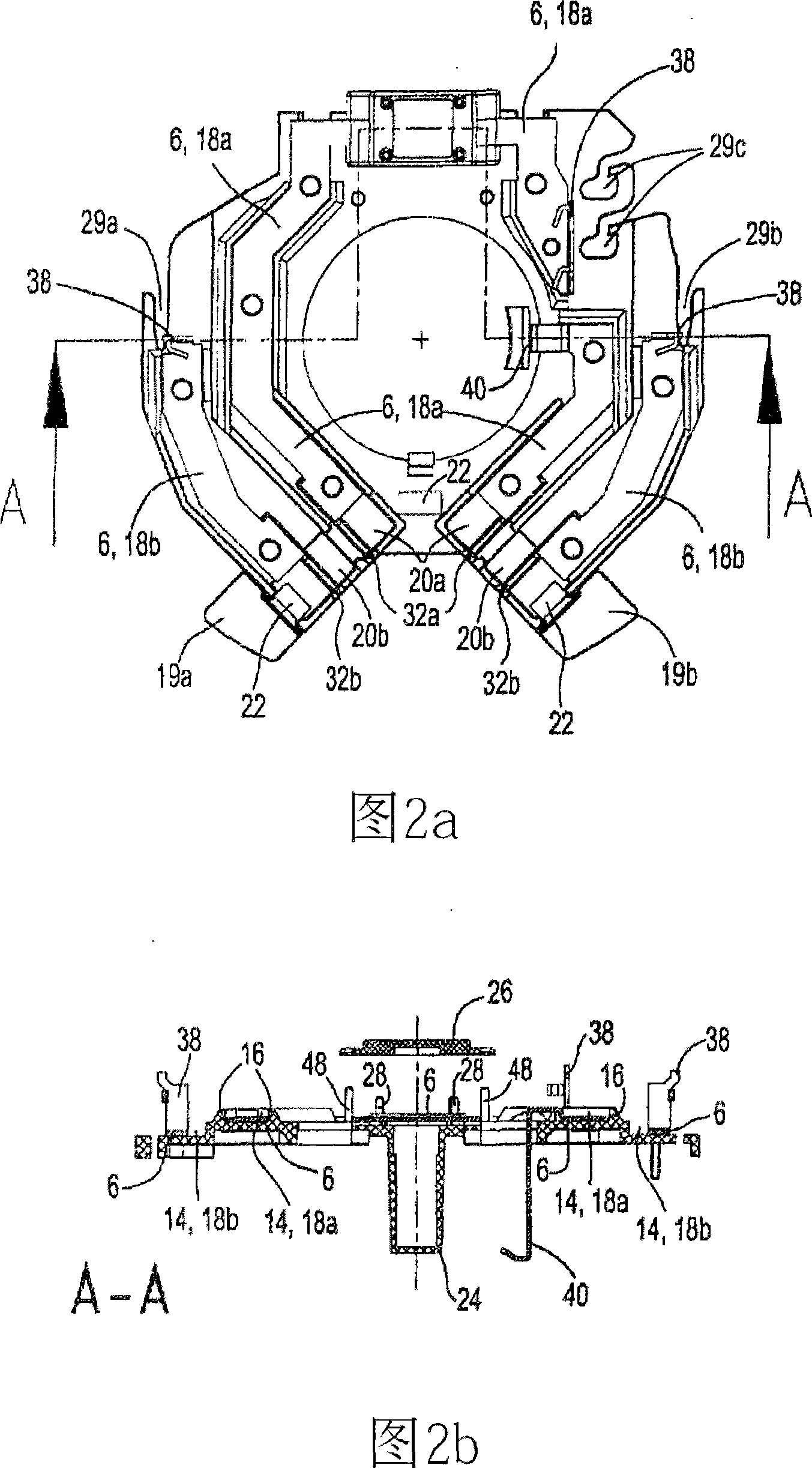

[0018] Fig. 1 is a perspective view showing a connection device 2 according to the invention as a separate component. The connecting device 2 comprises a circuit board 4 into which conductor strips 6 are inserted and sealed by a cover panel 8 . A plug element 10 associated with the connection device 2 is illustrated in FIG. 5 . The circuit board 4 has a circular receiving opening 12a for the end insulating rods of the stator and thus extends in a radial plane to the stator axis. The printed circuit board 4 is provided with a plurality of spacer pins 15 on its side facing the stator for position fixing and support purposes. On the side facing away from the stator, a conductor bar guide 14 bounded by an edge bar 16 is formed. At the base of the conductor bar guide groove 14, a plurality of positioning pins 17 protruding in the axial direction are integrally formed. The conductor bar guide grooves 14 extend substantially circumferentially in a higher inner polygonal train 18a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com