Optical fiber adapter of single-fiber bidirectional device and cubic metalwork assembly technology

A fiber optic adapter, single-fiber bidirectional technology, which is applied in the field of assembly technology of fiber optic adapters and square metal parts, can solve the problems of increasing processing costs, increasing the complexity and difficulty of metal parts, and the inability to accurately position 45-degree light filters, etc., to achieve The effect of reducing complexity and difficulty and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

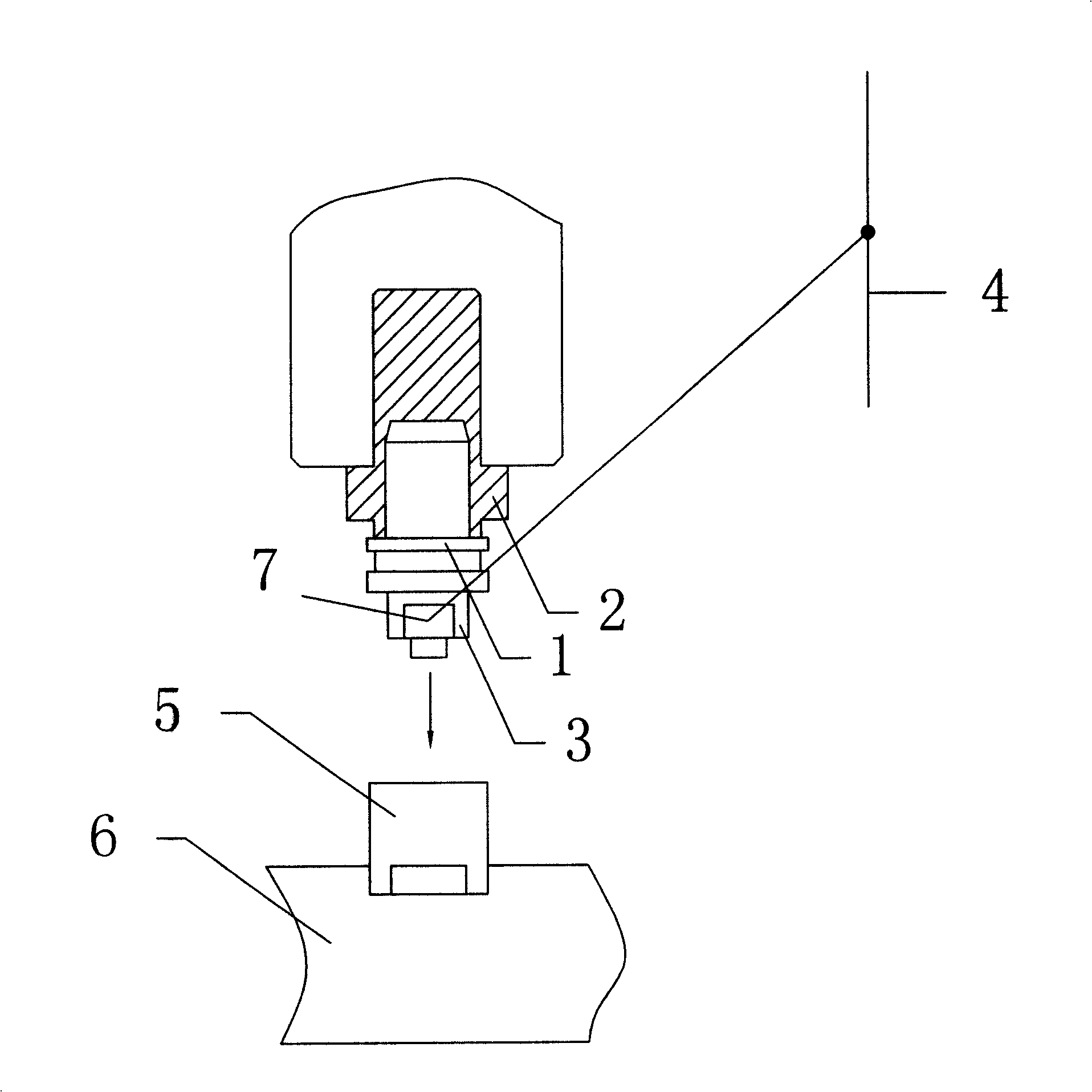

[0016] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

[0017] 1. This method uses a 650nm laser as the indicator light. This kind of laser is cheap, visible, and has good light directionality, and the light spot formed on the reflective screen is small, which can ensure the accuracy.

[0018] 2. This method uses the tight fit process to carry out the assembly process of the adapter and the square metal parts:

[0019] 1) Initial position calibration: In this method, first fix the position of the square metal part 5 and the coaxial center of the down-pressing jig 2 of the hand plate on the lower mold 6, lay it flat, and place a four-sided and square metal part 5 on the square metal part 5. A metal piece parallel to the metal piece 5, paste a small mirror surface on one of the outer surfaces of the metal piece, so that the side with the mirror is in the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com