Bidirectional ratchet mechanism

A ratchet mechanism and ratchet technology, applied in mechanical equipment, belts/chains/gears, wrenches, etc., can solve the problems of large elastic pressure resistance of ratchets and the inability of ratchet mechanisms to work, and achieve the effect of simple mechanism, large torque and few parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

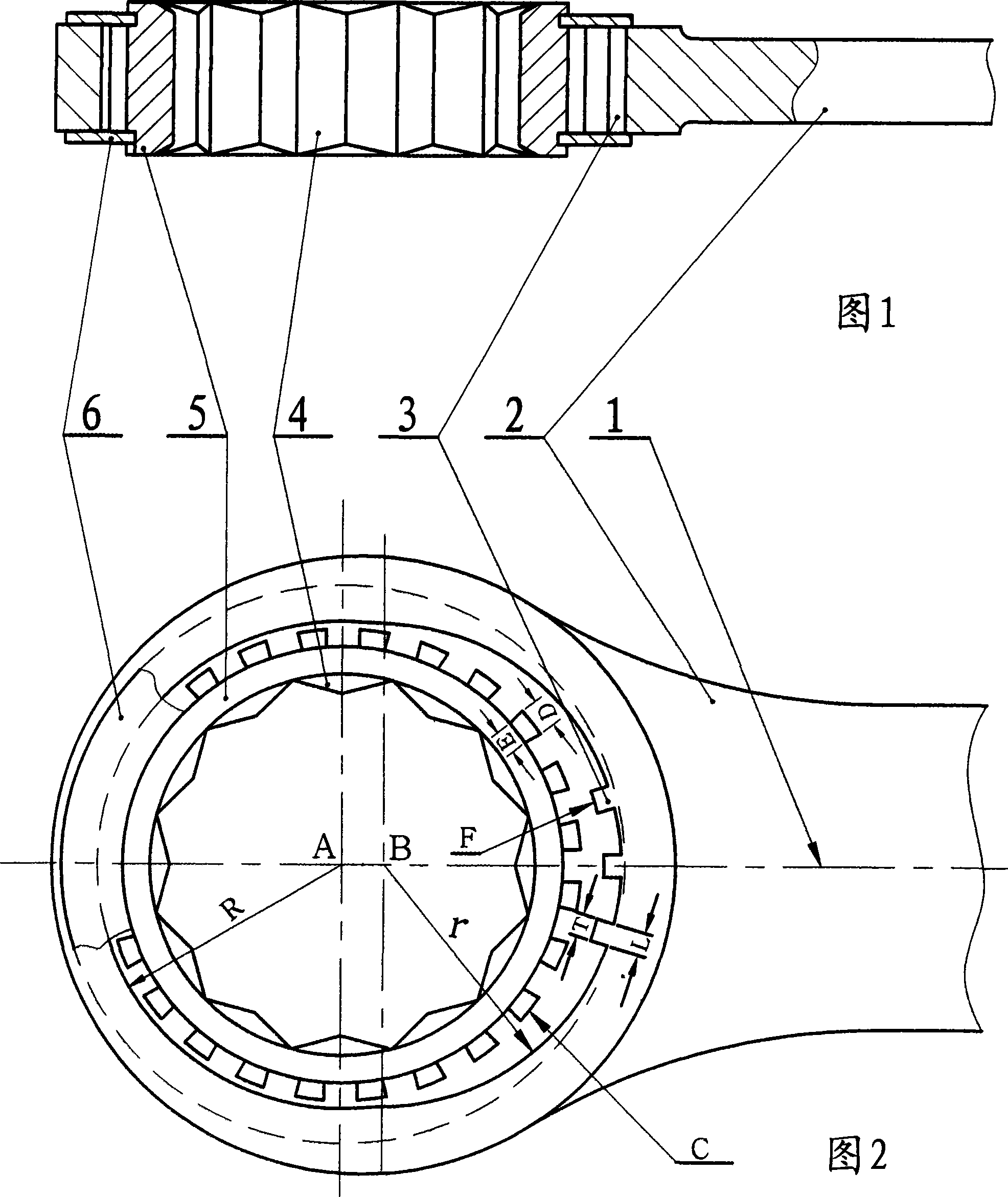

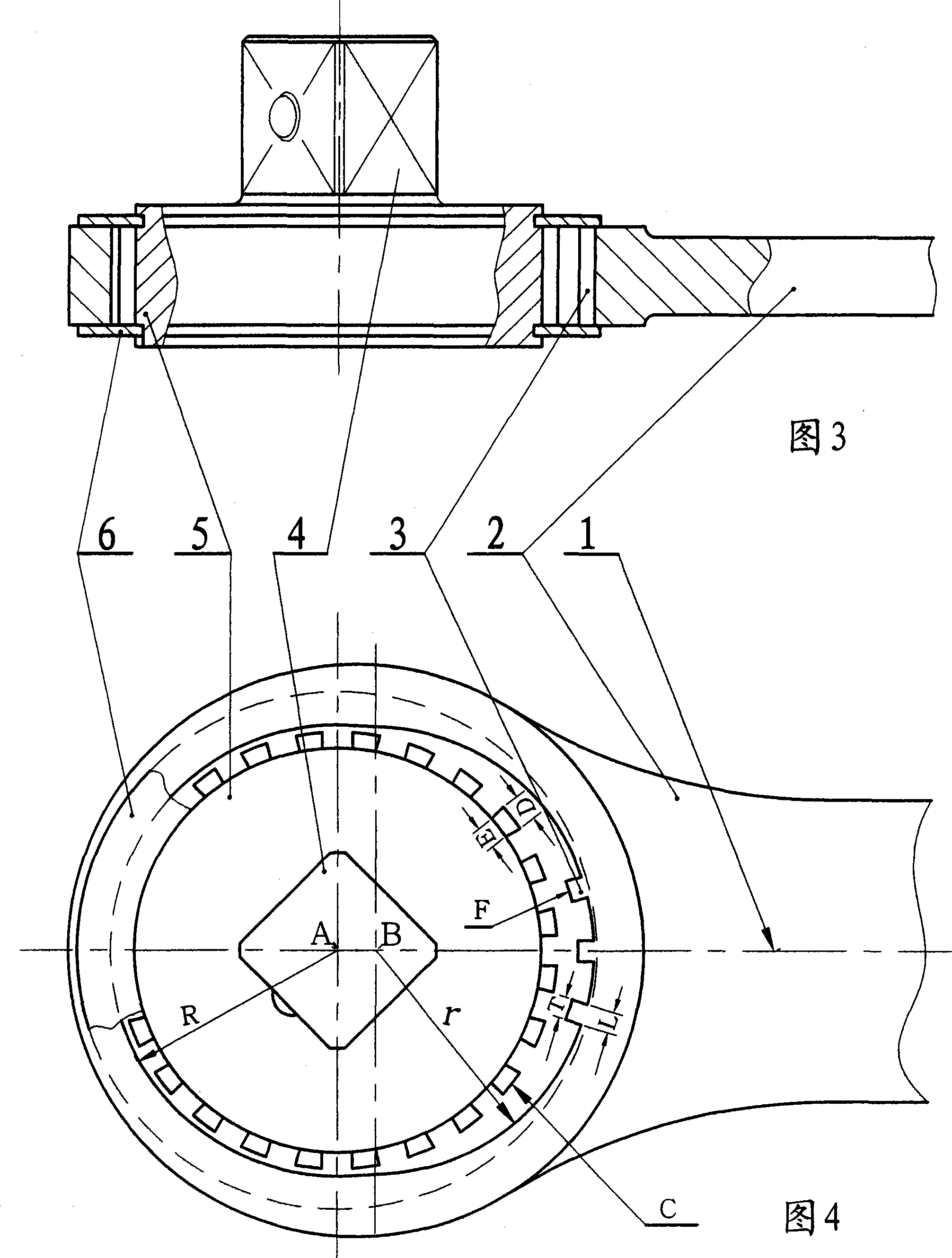

[0011] As shown in Figures 1 and 2 and Figures 3 and 4, on a plane with equal thickness, there is a through hole with two centers A and B, and the extension line connecting the centers A and B intersects at one end of the through hole R or r hole The wall is set as a center, and one to twenty internal teeth 3 are radially arranged on the hole wall, and a ratchet 5 with a ring of teeth is provided on the outer wall in the through hole, and the ratchet 5 can radially move along the direction of the circle center A and B. Moving back and forth, the teeth on the ratchet 5 can mesh with each tooth of the inner tooth 3, and can rotate radially together or reversely and separate to rotate independently. The radial outer wall of the through hole is connected with a handle 2, the middle line of the handle 2 is the handle center line 1, and the extension ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com