Three-electric motor self-synchronizing elliptical vibrating screen based on movement composition principle

A technology of elliptical vibration and motion synthesis, applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of difficult to meet the requirements of screening process, design difficulty, design and installation problems have not been improved, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

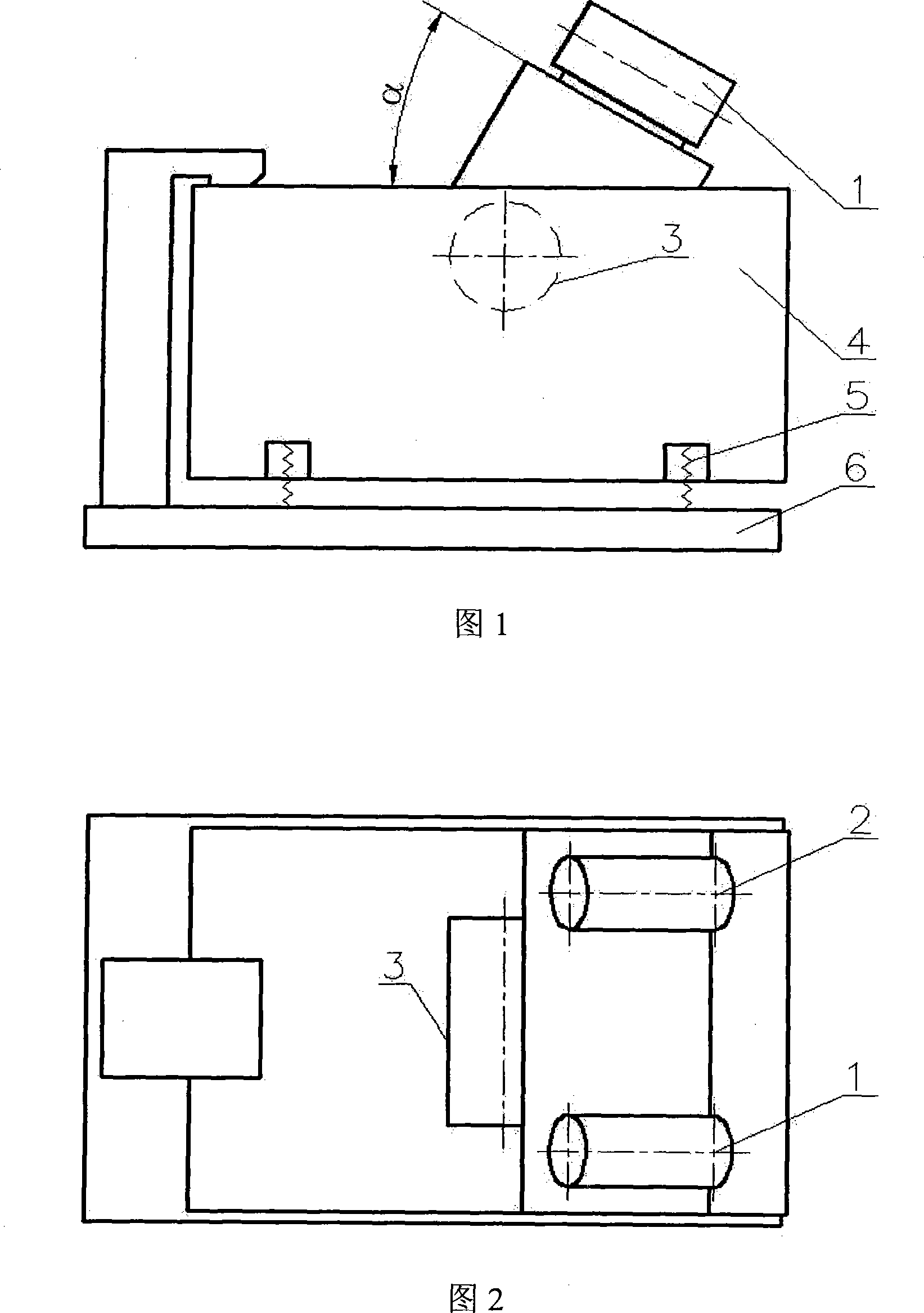

[0011] Further illustrate the present invention below in conjunction with accompanying drawing.

[0012] The three-motor self-synchronizing elliptical vibrating screen based on the principle of motion synthesis is mainly composed of vibration excitation motor 1, vibration excitation motor 2, vibration excitation motor 3, screen box 4, vibration damping spring 5, base 6, etc. It is characterized in that the vibration excitation The eccentric mass-diameter product of motor 1 and excitation motor 2 is equal, and the axes are installed on the motor base in parallel. There is an angle α between the motor base and the screen surface. When working, the vibration excitation motor 1 and the vibration excitation motor 2 rotate in the opposite direction at the same speed, and the excitation force generated by the two makes the screen box 4 vibrate in a straight line; the axis of the vibration excitation motor 3 and the excitation motor 1 and the vibration The axis of the motor 2 is verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com