Damping device, flat table device and exposuring device

A technology of an anti-vibration device and an exposure device, which is applied to a photo-engraving process exposure device, a microlithography exposure device, optics, etc., can solve the problem of the increase in the size of the voice coil motor and the increase in power consumption, the deterioration of the control accuracy of the exposure device, and the support object. OB deformation and other problems, to achieve the effect of small and lightweight vibration damping effect, good vibration damping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

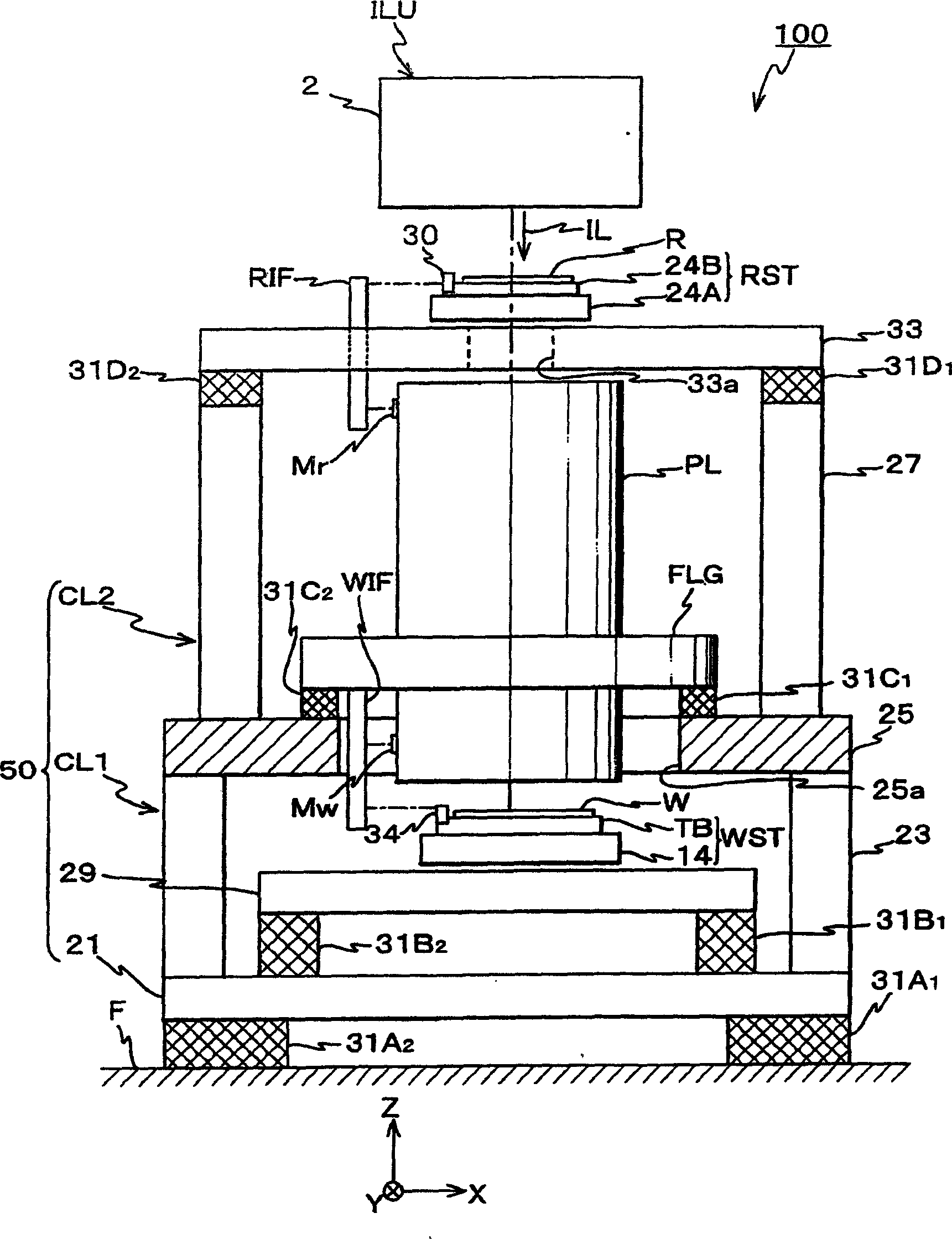

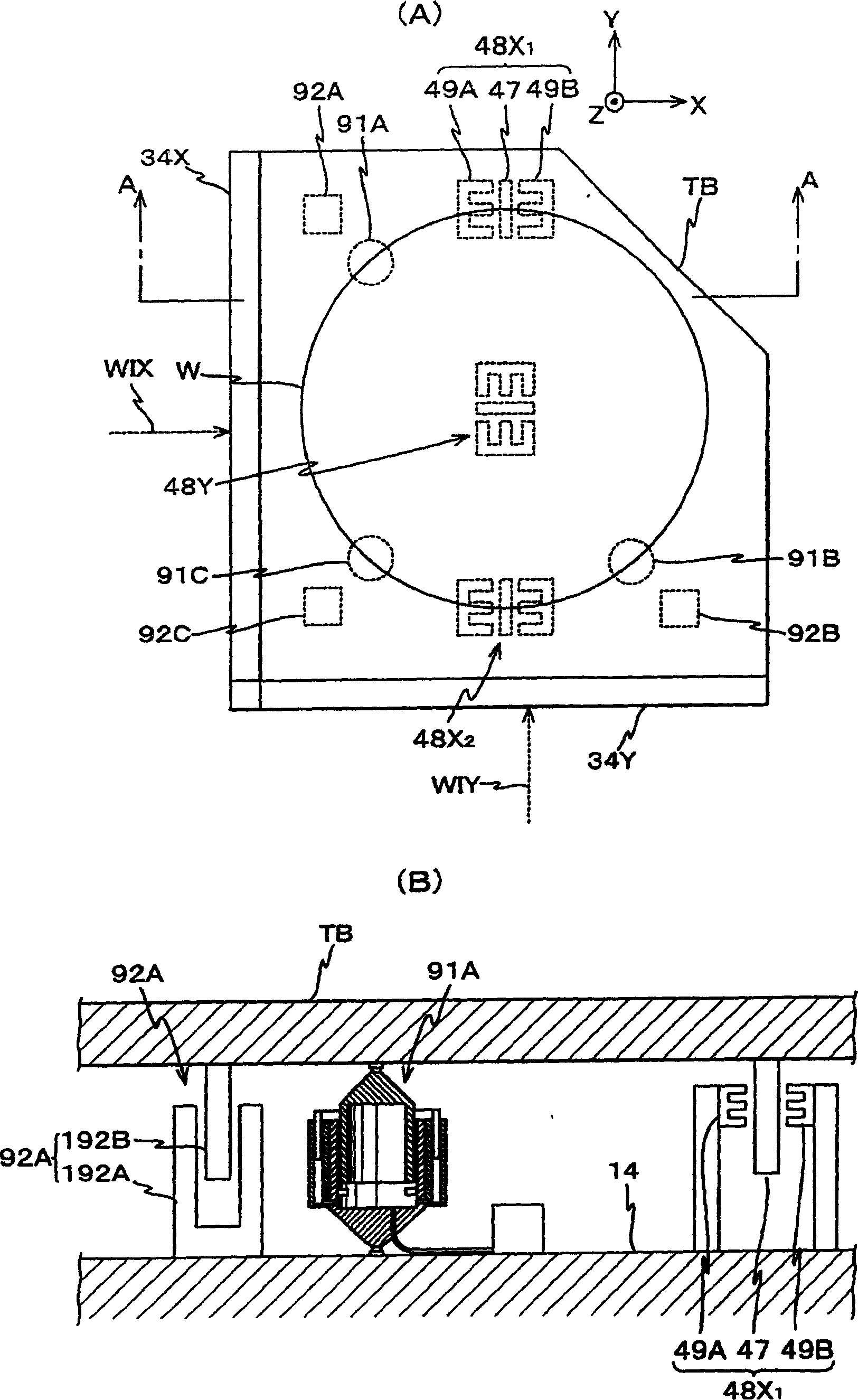

[0181] "First Embodiment"

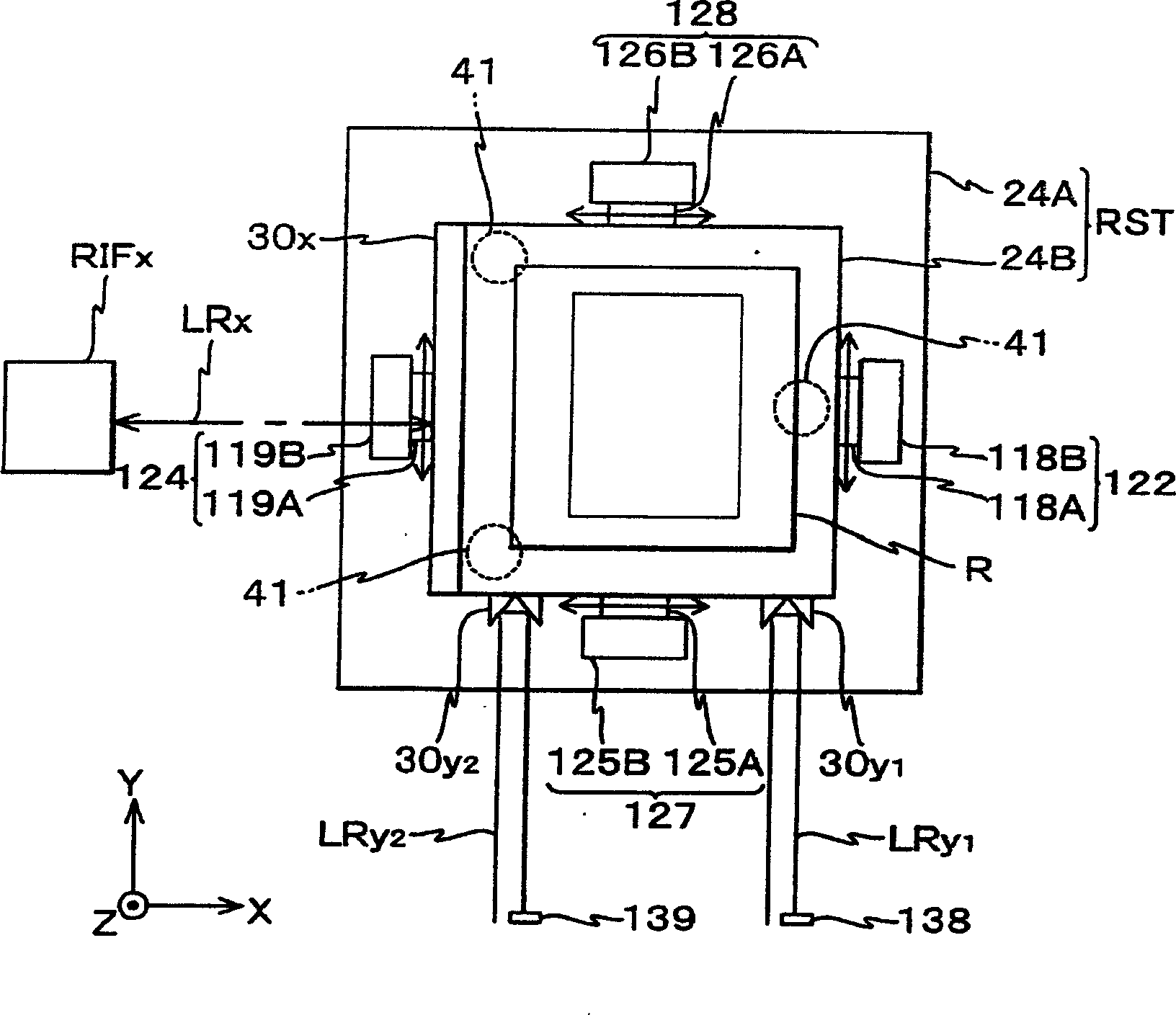

[0182] Below, according to Figure 1 to Figure 7 (B) The first embodiment of the present invention will be described. figure 1 The schematic diagram shows the overall configuration of the exposure apparatus 100 according to the first embodiment. This exposure apparatus 100 moves the grating R as a mask and the wafer W as a photosensitive object synchronously in one-dimensional direction, and transfers the circuit pattern formed on the grating R onto the wafer W through the projection optical system PL. A scanning exposure device of a step-and-scan method in an imaging area is a so-called scanning stepper exposure device.

[0183] The exposure apparatus 100 is provided with an illumination unit ILU for illuminating a rectangular slit-shaped illumination area on the grating R with uniform illuminance by means of illumination light for exposure as an energy beam (hereinafter simply referred to as "illumination light"), and as a holding grating. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com