Method for preparing cinepazid polymer emulsion adhesive without peculiar smell

A styrene-acrylic polymer, odorless technology, applied in the direction of hydrocarbon copolymer adhesives, adhesive types, etc., can solve the problems of affecting the bonding effect of adhesives to textile materials, the easy aggregation of activated carbon materials, and complex process conditions, etc. , to achieve excellent mechanical properties and water resistance, increase the storage period, and reduce the content of free monomers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

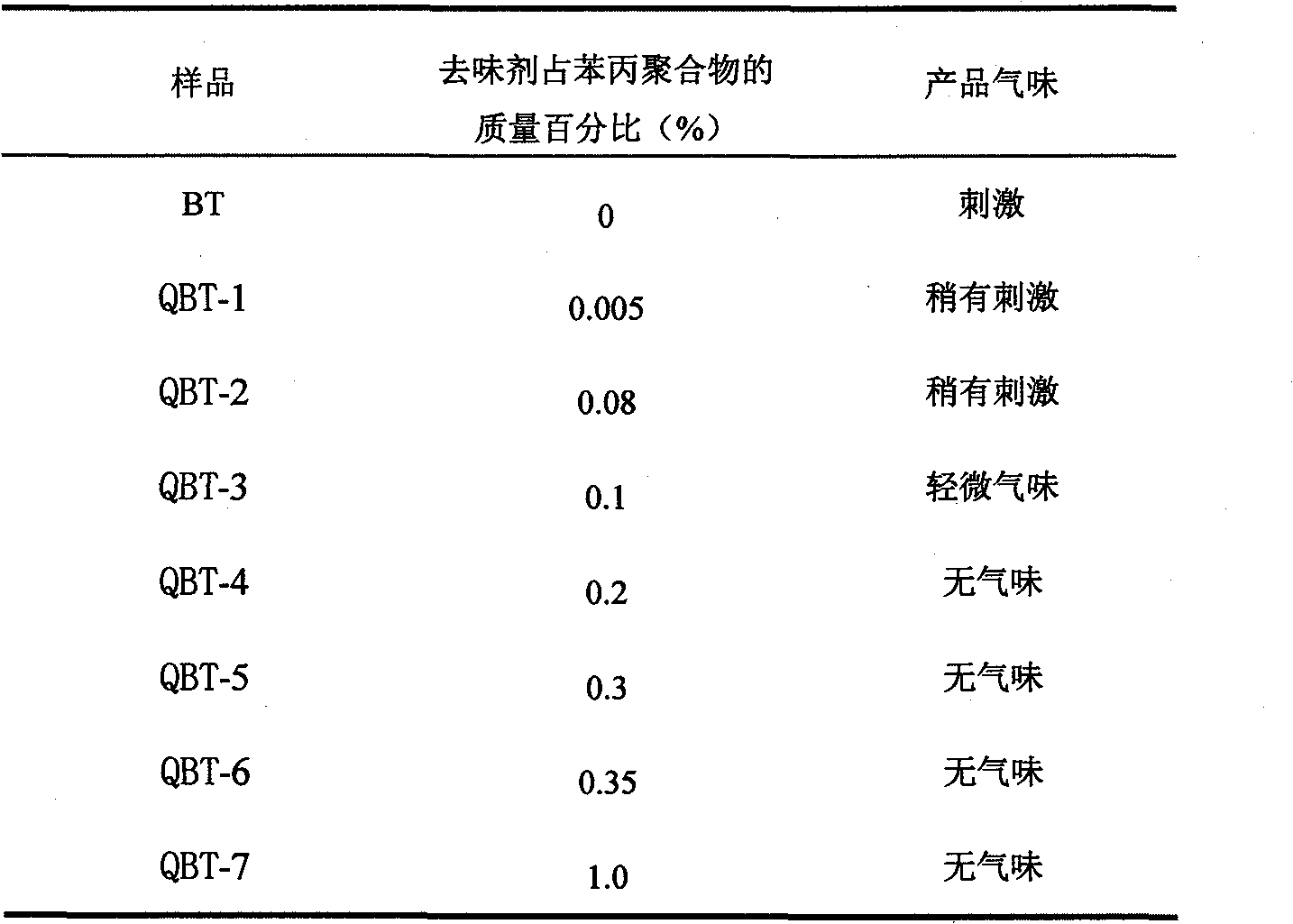

Embodiment 1

[0017] Add 0.04g of anionic emulsifier K 12 , 0.4g of non-ionic emulsifier Span and 845g of deionized water were emulsified for 10min, and under strong stirring, 0.4g of styrene and 0.04g of acrylic acid were added as seed monomers and 0.0022g of white carbon black to form a transparent seed microemulsion. Slowly raise the temperature to 40°C, add 0.04g of ammonium persulfate to initiate microemulsion polymerization, and slowly add the remaining 39.6g of styrene and 3.96g of acrylic acid dropwise after the emulsion turns blue, and finish the dripping within 4 hours, keep warm at 60°C for 6 hours, and then use 0.00055 g sodium hydroxide to adjust the pH value of the system to 6.5, continue stirring for 15 minutes, stop heating, cool and discharge, and obtain a translucent deodorant-modified styrene-acrylic polymer emulsion QBT-1 with a solid content of 5%.

Embodiment 2

[0019] Add 5.68g of anionic emulsifier POS, 1.14g of nonionic emulsifier Tween, and 33.8g of deionized water into a 250mL four-neck flask equipped with a stirrer, reflux condenser, thermometer, and feeding device for emulsification for 3 hours, and add 2g of benzene under vigorous stirring. Ethylene and 20g of methyl acrylate are used as seed monomers and 0.035g of white carbon black to form a transparent seed microemulsion. Slowly raise the temperature to 100°C, add 4.4g of azobisisobutyronitrile to initiate microemulsion polymerization, and slowly add the remaining 2g of styrene and 20g of methyl acrylate dropwise after the emulsion turns blue, and finish the dripping within 40 minutes, then keep the temperature at 110°C for 30 minutes, Then use 0.08g sodium bicarbonate to adjust the pH value of the system to 10.5, continue stirring for 15min, stop heating, cool and discharge, and obtain a translucent deodorant-modified styrene-acrylic polymer emulsion QBT-2 with a solid cont...

Embodiment 3

[0021] Add 6g of anionic emulsifier SDS, 2g of nonionic emulsifier Tween, and 179g of deionized water into a 500mL four-necked bottle equipped with a stirrer, reflux condenser, thermometer, and feeding device for emulsification for 1 hour, and add 9g of styrene and 6g of Methyl methacrylate was used as a seed monomer and 0.1 g of white activated carbon to prepare a transparent seed microemulsion. Slowly raise the temperature to 82°C, add 1.8g of potassium persulfate to initiate microemulsion polymerization, and slowly add the remaining 51g of styrene and 34g of methyl methacrylate dropwise after the emulsion turns blue, and finish the dripping within 2 hours, then keep the temperature at 92°C for 1.5h, Then use 3g of ammonium bicarbonate to adjust the pH value of the system to 8.9, continue stirring for 15min, stop heating, cool and discharge, and obtain a translucent deodorant-modified styrene-acrylic polymer emulsion QBT-3 with a solid content of 38%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com