Dust collecting container for electric vacuum cleaner

A technology for vacuum cleaners and containers, applied in the directions of vacuum cleaners, suction filters, applications, etc., can solve problems such as spilling and soiling of the ground, and achieve the effect of suppressing the reduction of attractive force and improving the dust collection ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0101] Next, specific embodiments of the present invention will be described with reference to the drawings.

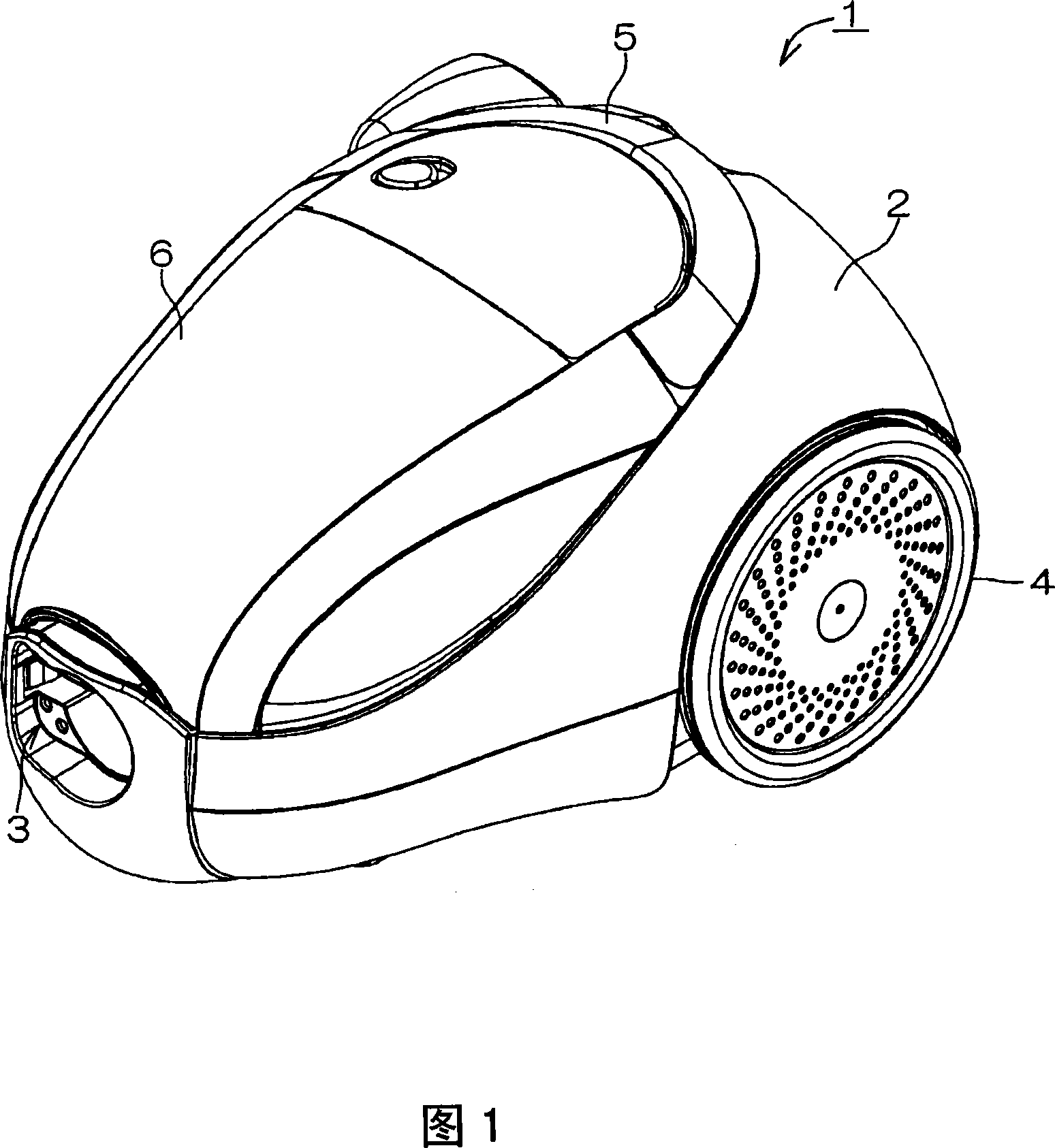

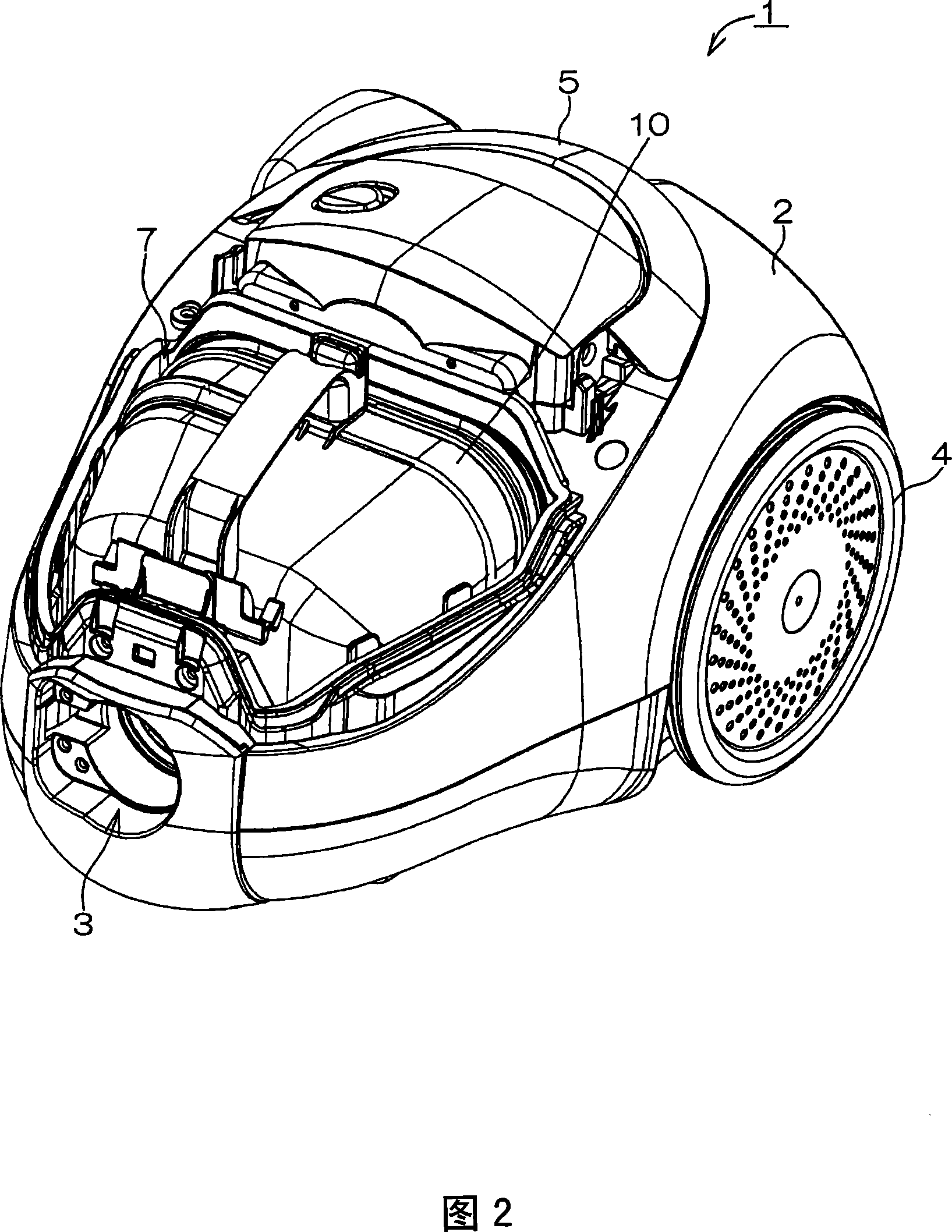

[0102] Fig. 1 is a perspective view of a vacuum cleaner main body 1 according to an embodiment of the present invention. In the electric vacuum cleaner main body 1 shown in FIG. 1 , the left obliquely lower side is referred to as the front, and the right obliquely upper side is referred to as the rear. Up and down are also specified according to this direction.

[0103] The main body 1 is defined by, for example, a case 2 formed of resin, and a suction hose attachment hole 3 is formed in the front of the case 2 . In addition, wheels 4 with relatively large diameters are installed on the left and right sides near the rear of the casing 2 . In addition, a handle 5 that can be erected from the illustrated folded state to an erected state is provided on the upper surface of the housing 2 . An openable and closable cover 6 is disposed on the front side of the handle 5 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com