Composition for polyurethane foam, polyurethane foam obtained from the composition, and use thereof

A technology of polyurethane foam and composition, applied in the field of composition for polyurethane foam, can solve the problems of inability to obtain, increase in hardness, etc., and achieve the effects of reducing environmental load, excellent resilience, and excellent low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0151] [Example]

[0152] Hereinafter, although an Example demonstrates this invention in more detail, this invention is not limited to these Examples. "Parts" and "%" in the examples represent "parts by mass" and "% by mass", respectively. Analysis and measurement in Examples and Comparative Examples were performed by the following methods.

[0153] (1) core density (in the table of embodiment, core density is abbreviated as " Dco ")

[0154] The measurement was carried out in accordance with the measuring method of apparent density described in JIS K-6400. In the present invention, the skin of the foam sample is removed to form a cuboid foam sample, and the core density is measured.

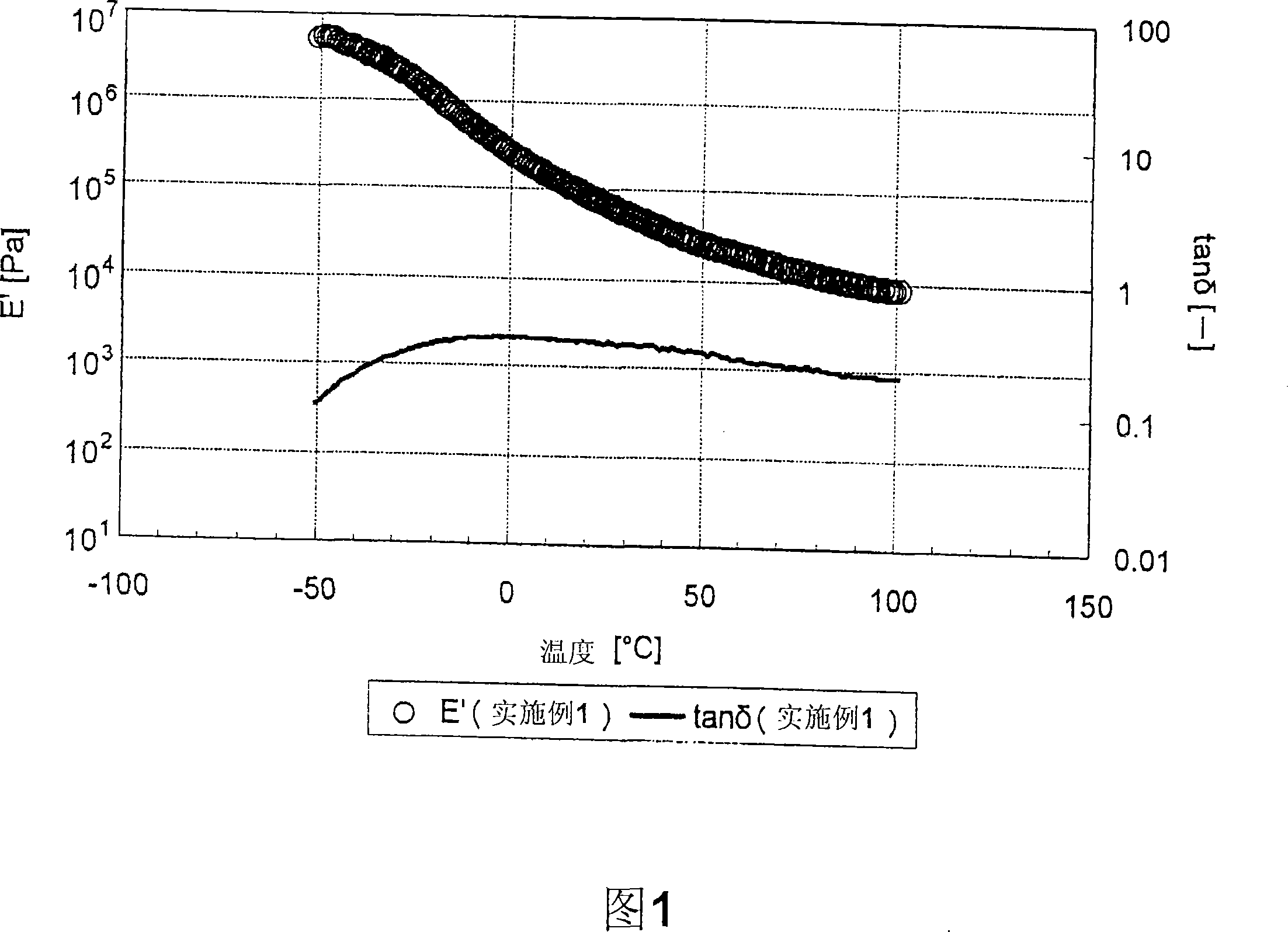

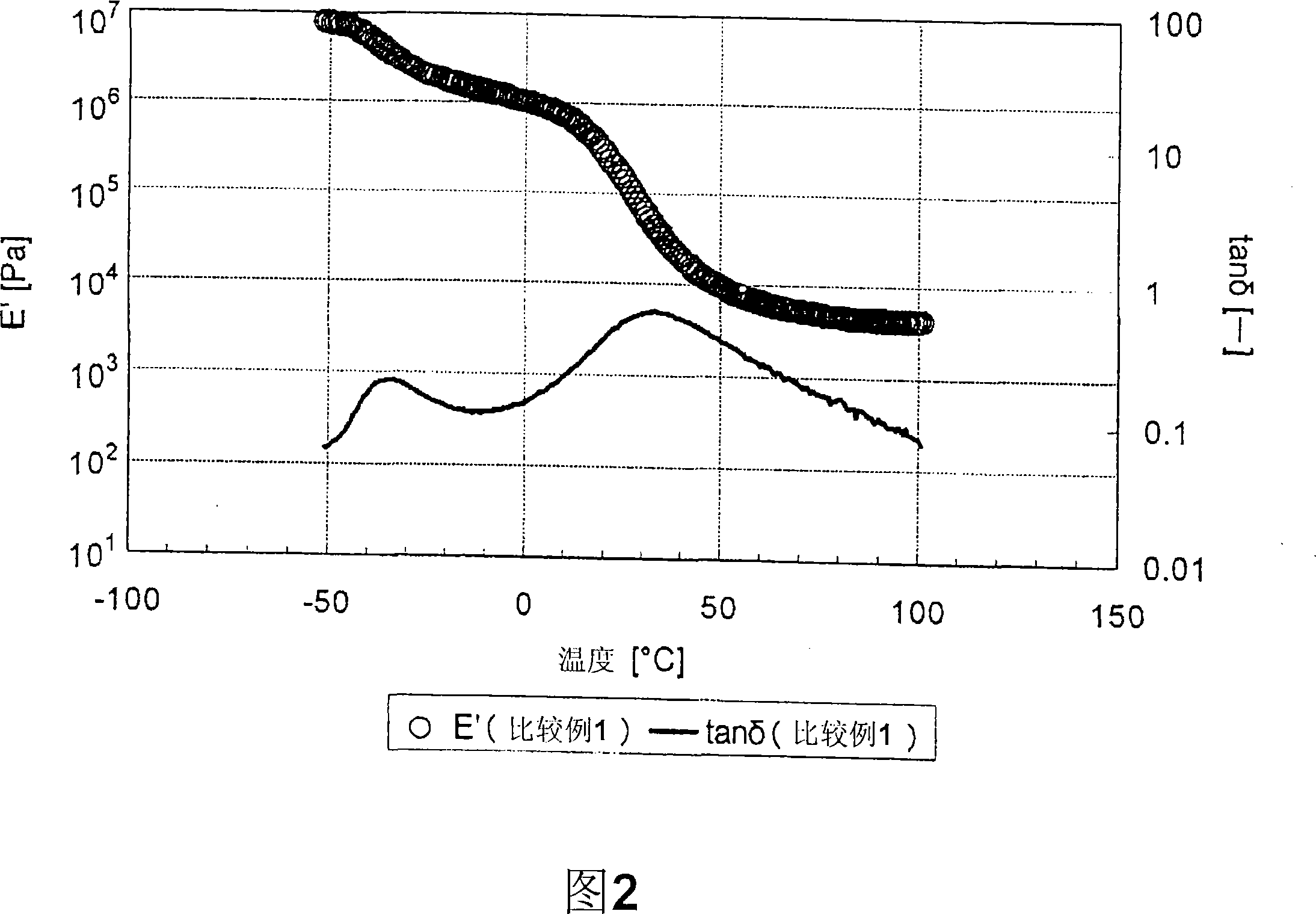

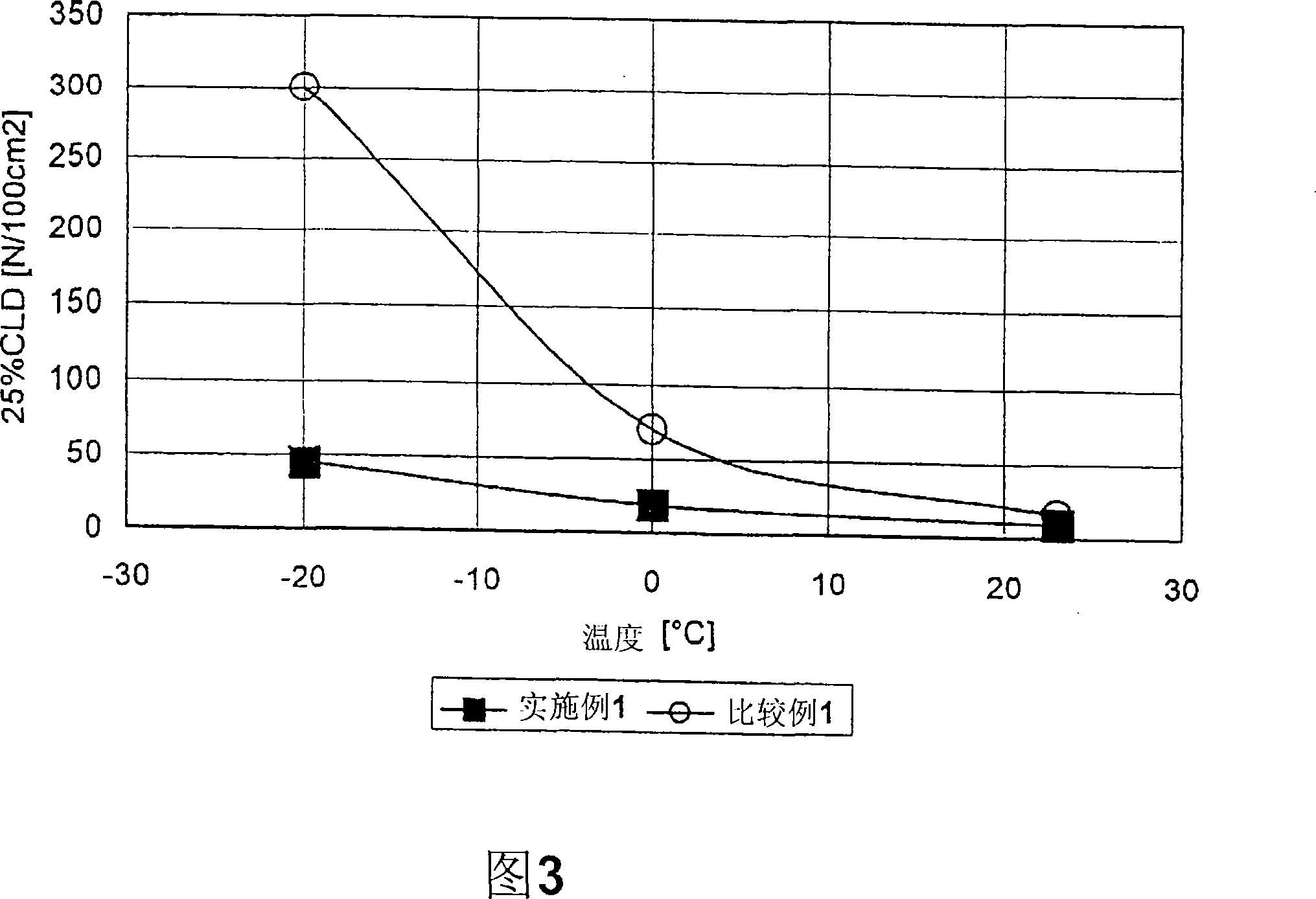

[0155] (2) hardness of foam (in the table of embodiment, abbreviation is done " 25%CLD ")

[0156] The measurement was carried out according to method A described in JIS K-6400. However, the measurement was performed on a foam having a thickness of 50 mm. In the hardness measurement, pre-...

Synthetic example 1

[0169] In a reactor with a stirrer, a thermometer, a nitrogen introduction pipe, and a reflux condenser, 1192 g (4 mole ) and 1200 g (4 mol) of hydrogenated castor oil fatty acid having an acid value of 187 mgKOH / g were subjected to a condensation reaction at a temperature in the range of 180 to 230° C. for 2 hours under a nitrogen atmosphere. During this condensation reaction, generated water was distilled off to the outside of the system. Thus, a hydroxycarboxylic acid oligomer having an acid value of 70 mgKOH / g was obtained. The hydroxycarboxylic acid oligomer corresponds to a 2.7-mer of an equimolar mixture of castor oil fatty acid and hydrogenated castor oil fatty acid.

[0170] Next, in the above-mentioned reactor, 92 g (1 mole) of glycerin was added as a polyhydric alcohol, and titanium lactate [(HO) was added as a catalyst. 2 Ti(C 3 h 5 o 3 ) 2 ] 2.6 g (0.01 mol), and carried out the condensation reaction at a temperature in the range of 180 to 230° C. for 8 hour...

Synthetic example 2

[0172] To 1 mole (2340 g) of the plant-derived polyol (B5-1) obtained in Synthesis Example 1 with a hydroxyl value of 60 mgKOH / g, tetrakis[tris(dimethylamino)phosphinoideneamino]phosphonium hydroxide was added Tetrakis[tris(dimethylamino)phosphoranilidenamino]phosphonium hydroxide) 0.01 mole (7.6g), dehydration under reduced pressure at 100°C for 6 hours. Thereafter, at a reaction temperature of 80°C and a maximum reaction pressure of 3.8kg / cm 2 Propylene oxide is subjected to addition polymerization under certain conditions. Next, at a reaction temperature of 100°C and a maximum reaction pressure of 3.8kg / cm 2 Under the conditions, the addition polymerization of ethylene oxide is carried out to obtain the plant-derived polyol (B6-1). The polyol (B6-1) contains 8 C 6 h 13 The side chain represented by (hexyl) had a hydroxyl value of 49 mgKOH / g, an average number of functional groups of 2.5, and a terminal oxyethylene group content of 15% by mass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com