Method for testing fluid bed reactor distributing plate

A technology of a fluidized bed reactor and a detection method, which is applied in the direction of using sound waves/ultrasonic waves/infrasonic waves to analyze fluids, etc., which can solve problems such as system flow and reaction influence, human injury, and differential pressure gauge blockage, and meet the requirements of low measurement conditions. Easy and convenient installation, small measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

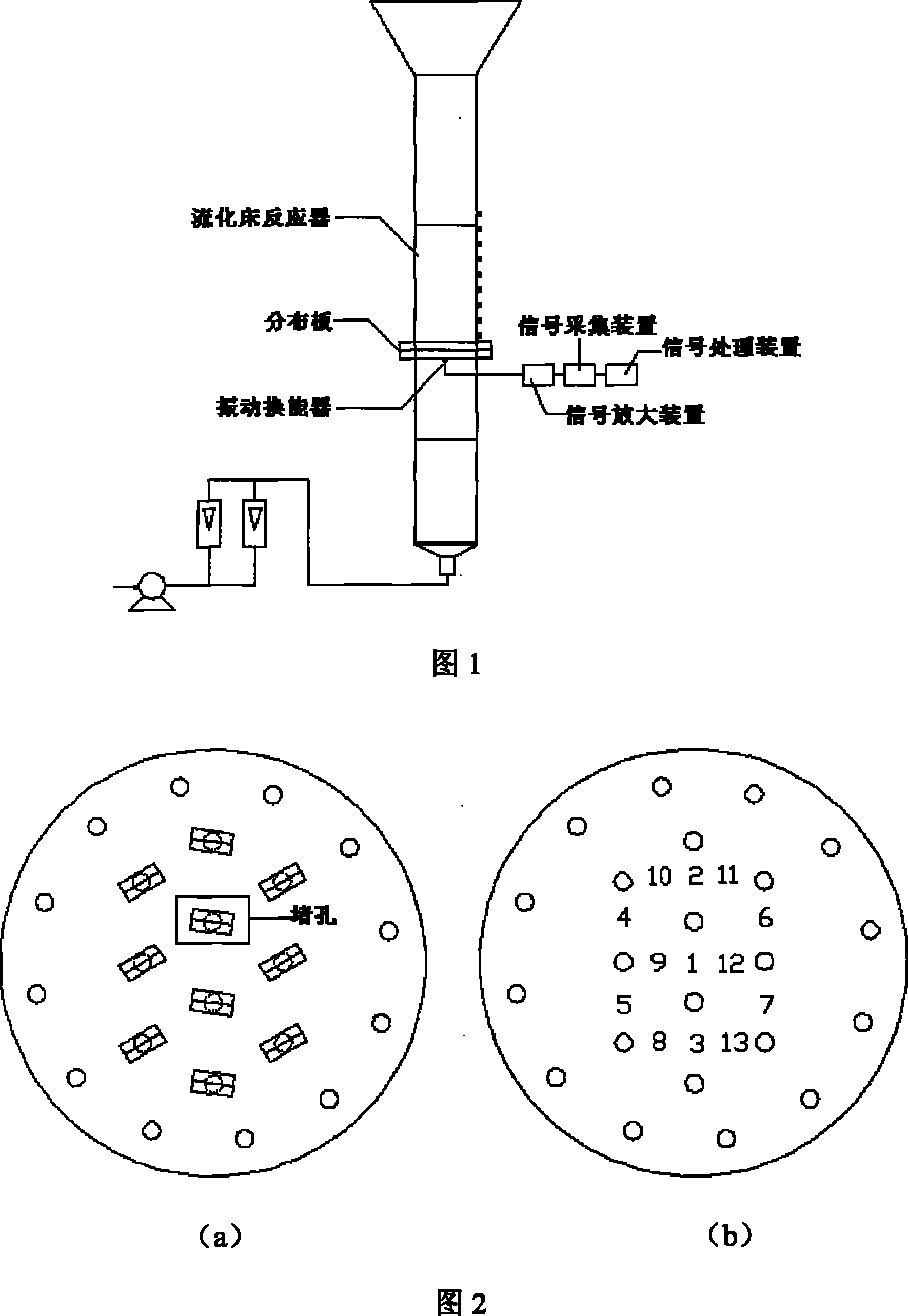

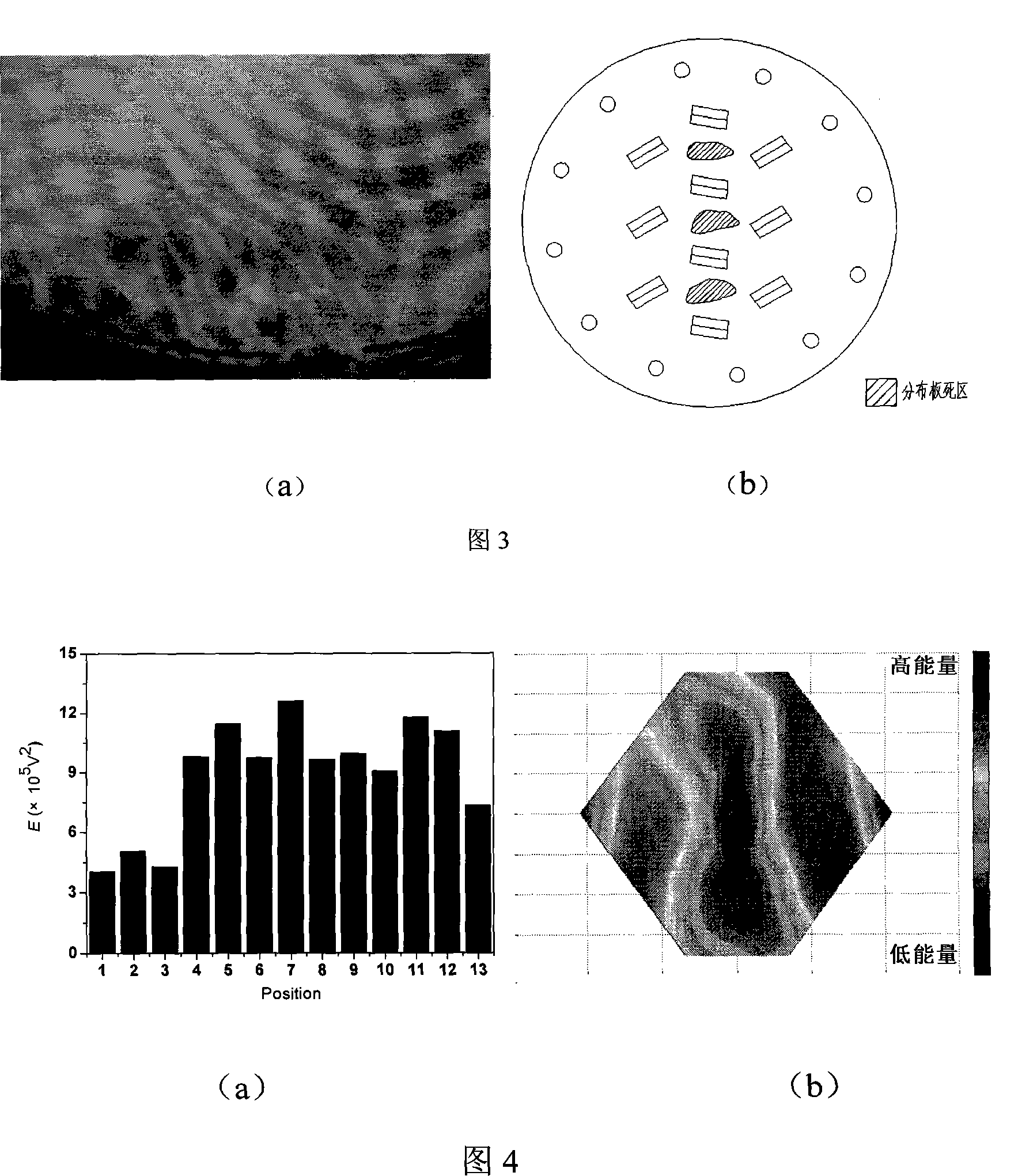

[0052] use as figure 1 Device diagram, in a gas-solid fluidized bed made of plexiglass with a height of 1000mm and an inner diameter of 150mm, with figure 2 The distribution plate shown is the experimental object, the hole diameter is 2.0mm, and the opening ratio is 2.6%. Attached to the distribution plate as image 3 Polyethylene particles distributed as shown on the right to create dead zones and agglomerates. Air is used as the fluidizing gas, the superficial gas velocity is 0.65m / s, and the static bed height is 500mm. Passive acoustic emission sensors are attached to different positions under the distribution board (such as figure 2 ), and the distances from the inlet holes of the adjacent distribution plates are 0.15L, 0.25L, and 0.5L respectively, where L is the minimum hole spacing of the distribution plate. The sampling frequency is 200kHz, and the sampling time is 5s.

[0053] The energy analysis of the acoustic emission signal is obtained as Figure 4 The ene...

Embodiment 2

[0055] use as figure 1 Device diagram, in a gas-solid fluidized bed made of plexiglass with a height of 1000mm and an inner diameter of 150mm, with figure 2 The distribution plate shown is the experimental object, the hole diameter is 2.0mm, and the opening ratio is 2.6%. Air is used as the fluidizing gas, the superficial gas velocity is 0.65m / s, the static bed height is 500mm, the sampling frequency is 95MHz, and the sampling time is 5s. Also first measure the acoustic emission signals at 13 points below the distribution plate when all the hoods are working normally, and then block a plate hole or hood above the center of the distribution plate (such as figure 2 ), and then measure the acoustic emission signals at the same 13 points below the distribution plate. Passive acoustic emission transducers are attached to different positions below the distribution board (such as figure 2 ), and the distances from the inlet holes of the adjacent distribution plates are 0.15L, 0...

Embodiment 3

[0059] use as figure 1 In the diagram of the device, the gas-solid fluidized bed is transparent organic glass with a height of 3000mm and an inner diameter of 250mm, and the height of the static bed is 800mm. image 3 The distribution plate shown is the experimental object, the hole diameter is 2.0mm, and the opening ratio is 2.6%. Using air as the fluidizing gas, the gas velocity changes from 0 to 0.8m·s -1 . The operating temperature is room temperature. The sampling frequency is 800kHz, and the sampling time is 10s. The passive acoustic emission transducer is attached to position 1 under the distribution board.

[0060] Measure the acoustic signal generated by the fluidization of particles with an average particle diameter of 0.64mm as the gas velocity gradually increases. The energy ratio and variance ratio of the acoustic signal are basically stable at about 1 to 2 with the change of air velocity. When the gas velocity reaches the critical fluidization velocity, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com