Top thread gripper mechanism used for embroidery machine

A clamping mechanism and technology for embroidery machines, which are applied to the mechanism of embroidery machines, embroidery machines, textiles and paper making, etc., can solve the problems of falling off the upper thread, stopping the upper thread, not effectively controlling the thread trimming, and inconsistent length of the thread trimming. , to achieve a fixed and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the drawings and embodiments:

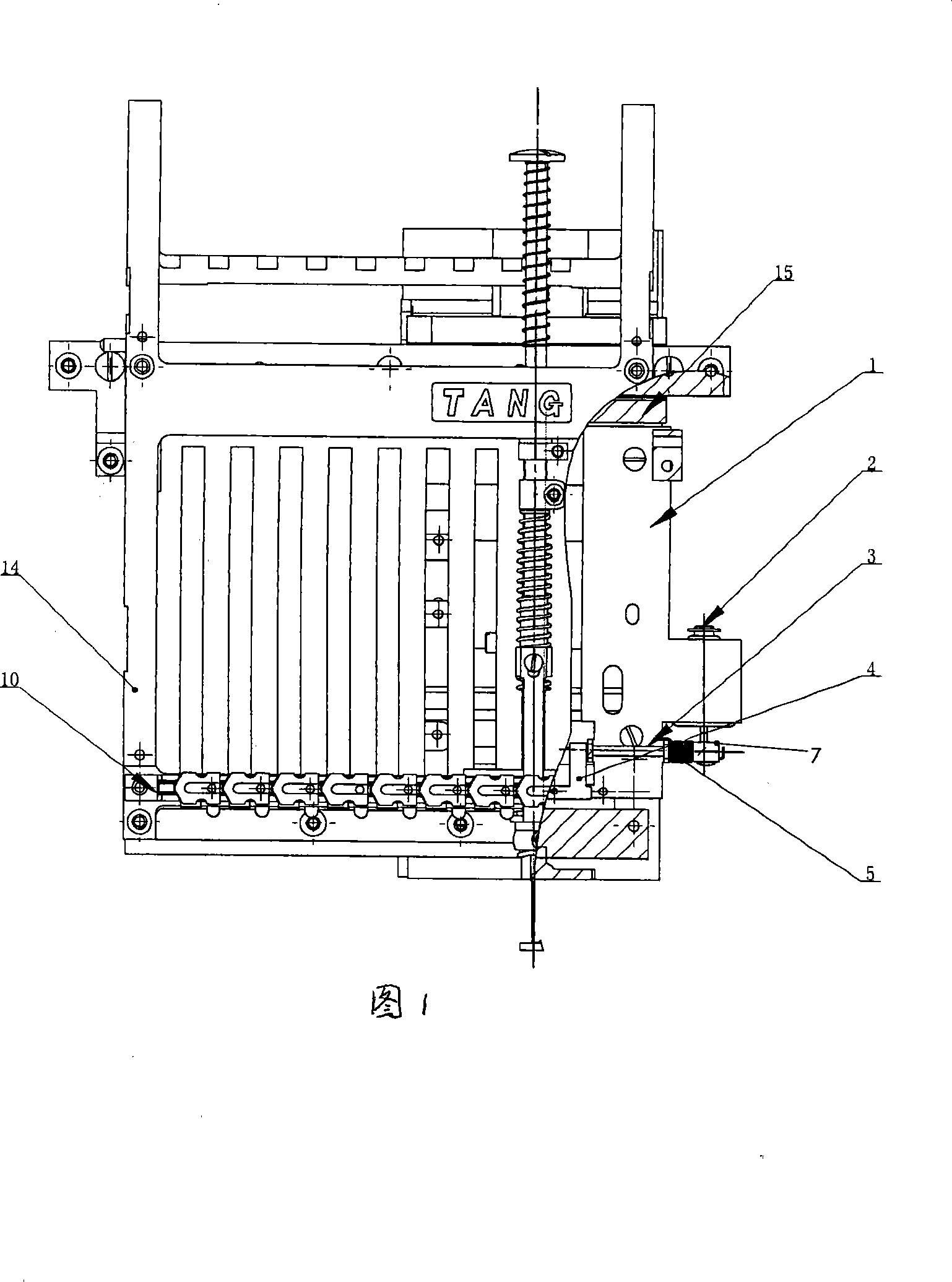

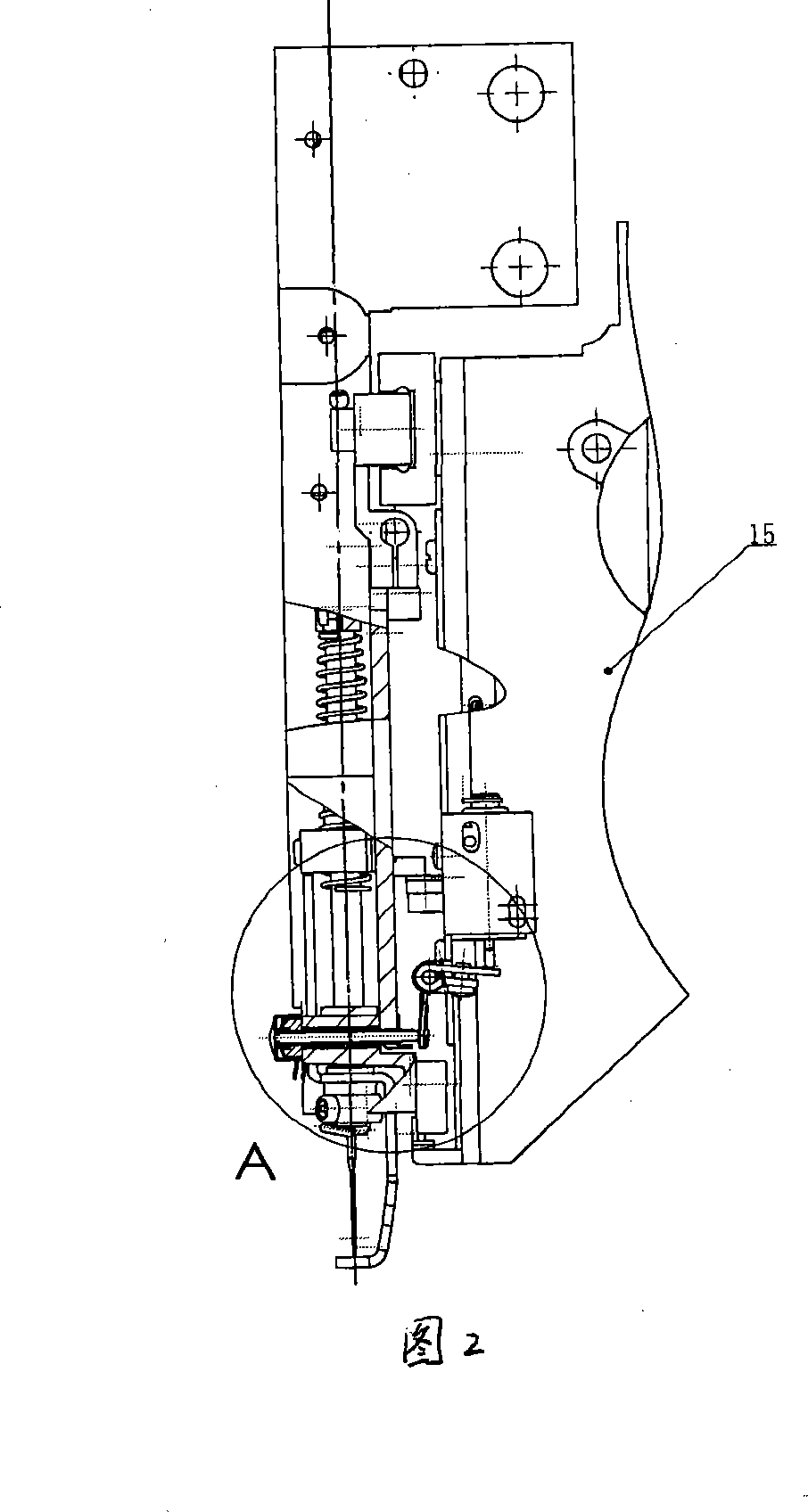

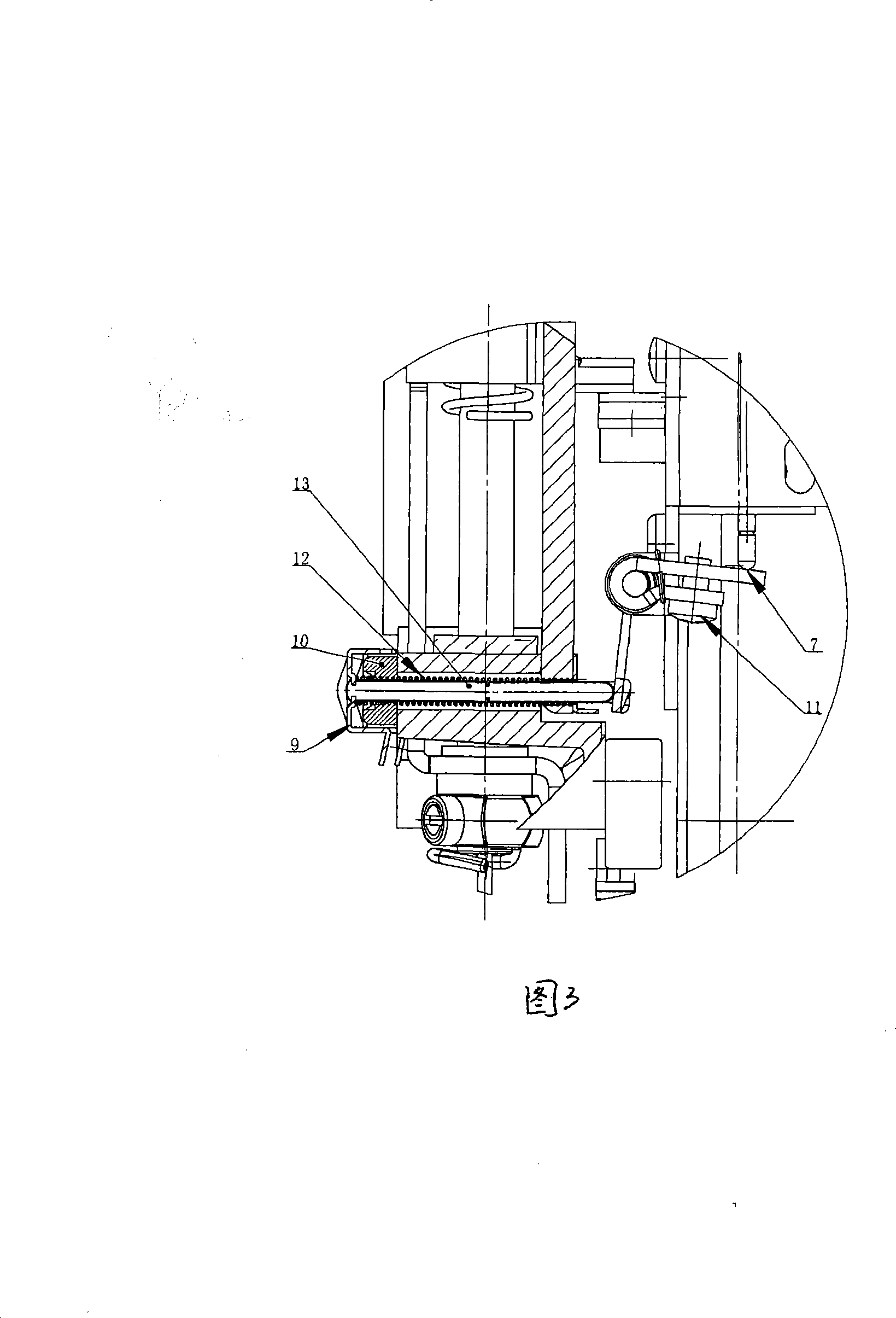

[0022] As shown in the figure, the upper thread clamping mechanism used on the embroidery machine includes a machine head 15 and a needle bar frame 14. An electromagnet seat 1 is installed on the right side of the machine head 15, and an electromagnet is installed on the electromagnet seat 1 2. The electromagnet seat 1 is also equipped with a synchronization shaft 3, one end of the synchronization shaft 3 is fixedly connected with a lever plate 4, the other end of the synchronization shaft 3 is connected with an adjustable lever plate 7, the adjustable lever plate 7 and the electromagnet core shaft 2 One end is mated and connected; the adjustable lever plate 7 is provided with a screw 11 for locking the relative position of the adjustable lever plate 7 and the synchronization shaft 3. When the adjustable lever plate 7 is adjusted to the required angle, it is locked and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com