Prefabricated combined type anaerobic tank

A prefabricated group and septic tank technology, applied in biological sludge treatment and other directions, can solve the problems of short construction period, hidden dangers, low cost, etc., and achieve the effects of good docking, stable installation and low requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

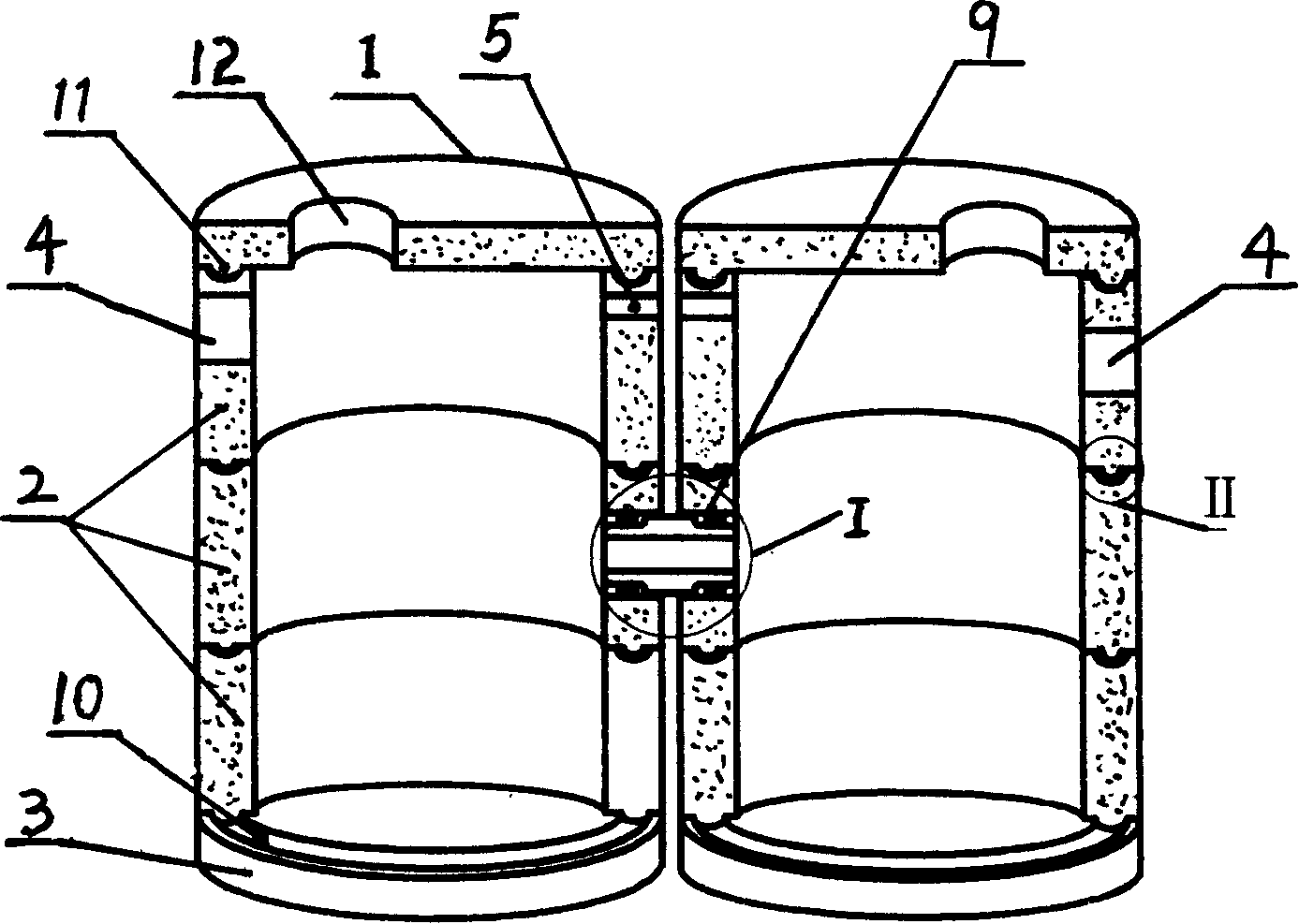

[0012] Embodiment 1: Referring to the accompanying drawings, at first, it is mainly composed of a reinforced concrete prefabricated pool cover 1, a ring pool 2 and a pool bottom 3, wherein the pool cover 1 is provided with a wellhead 12 and a convex ring 11, and the pool bottom 3 is provided with Concave ring 10, the upper end of the ring pool 2 is provided with a concave ring 10, and the lower end is provided with a convex ring 11. When connecting, the side of the pool bottom 3 with the concave ring 10 is placed horizontally upwards, and placed in the concave ring 10 of the pool bottom 3. cement slurry 8, then put the convex ring 11 of the first ring pool 2 into the concave ring 10 of the pool bottom 3, put the cement slurry 8 in the concave ring 10 on the upper end of the first ring pool 2, and then place the first The convex rings 11 of the two ring pools 2 are placed in alignment with the concave ring 10 of the first ring pool 2, and a plurality of ring pools 2 are placed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com