Crane used for maintenance of large-scale wind power equipment

A technology for wind power equipment and cranes, which is applied in the field of wind power equipment maintenance cranes, which can solve the problems of high hoisting and transportation costs, long hoisting cycle, and high cost, and achieve the effect of timely maintenance and repair and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

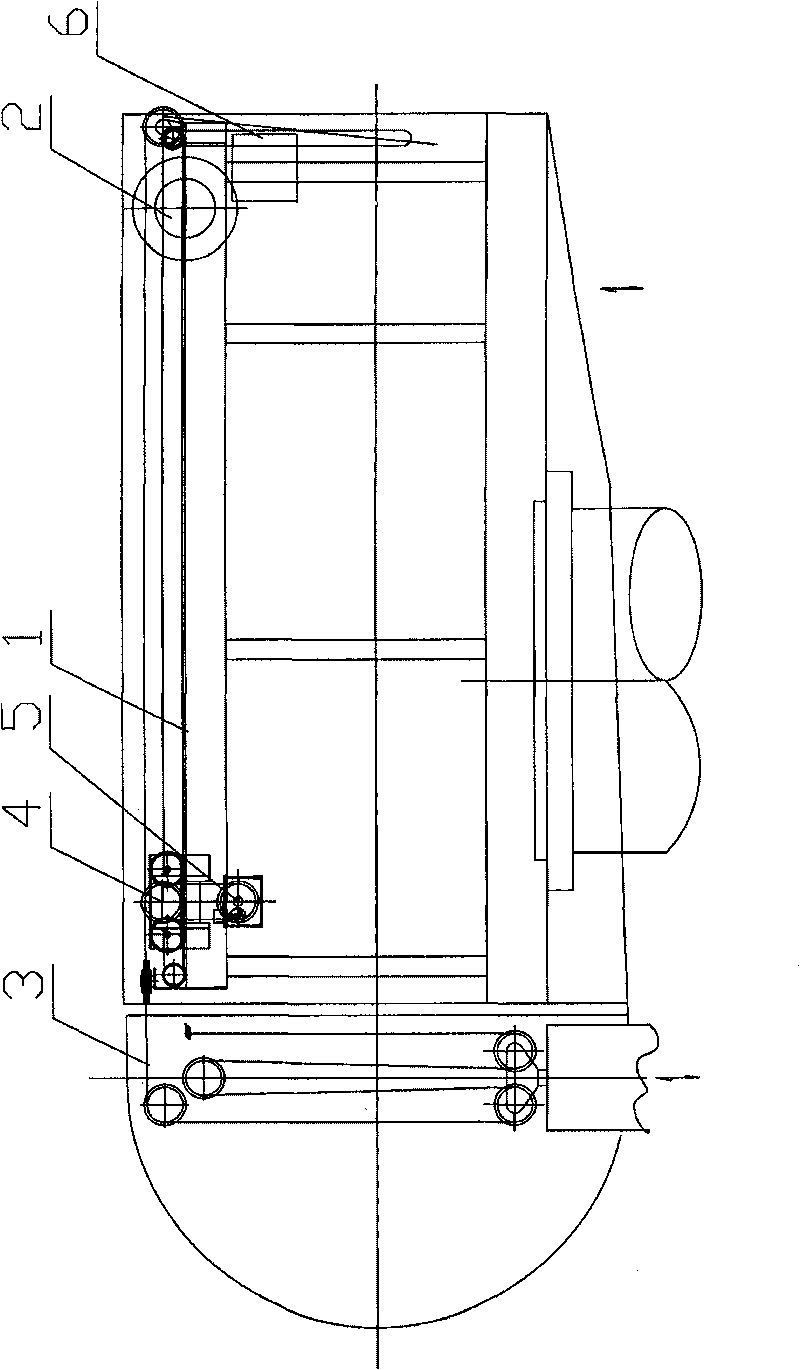

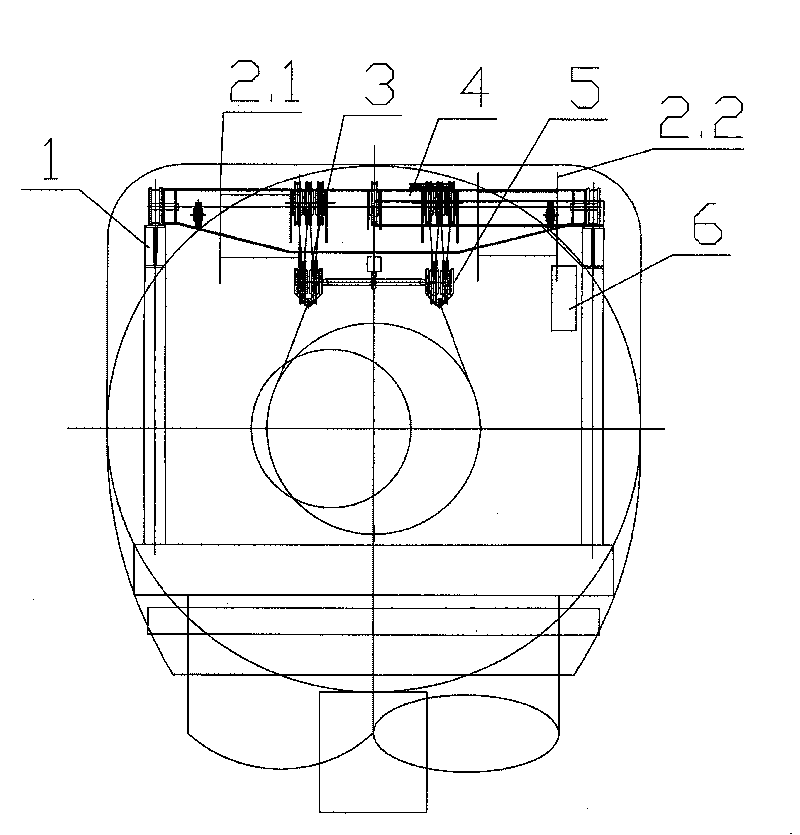

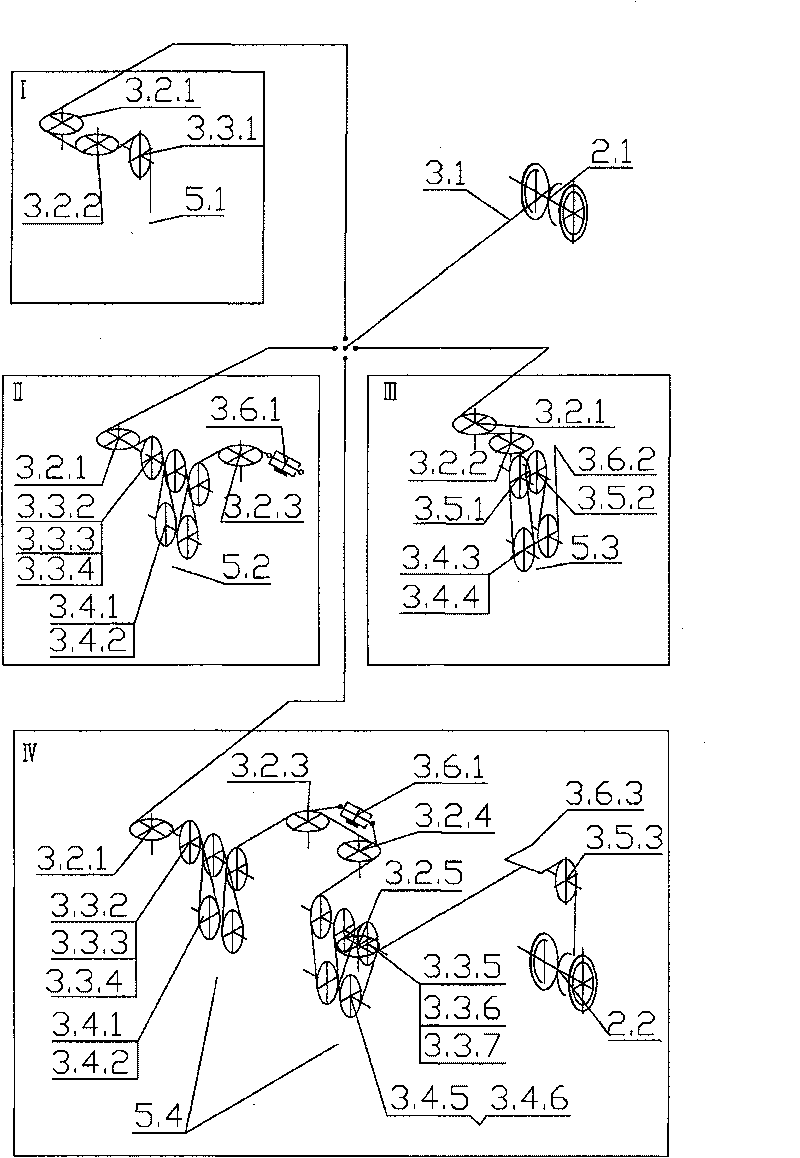

[0033] Such as Figure 1~4 The shown maintenance crane for large-scale wind power equipment includes: steel structure 1, hoisting drive mechanism 2, differential weight variable magnification hoisting rope system 3, trolley and its traction and anti-sway device 4, special spreader 5 and The electrical control system 6 is mainly based on a driving unit, that is, the lifting driving mechanism 2.1. By changing the winding mode of the ropes, that is, the paths I, II, III and IV, and using special spreaders 5.1 to 5.4, small and large lifts in the engine room can be realized. The normal lifting function of the components can meet the lifting needs during the implementation of medium and large overhauls, and can also take into account the lifting needs of the blades outside the nacelle.

[0034] The trolley in the present invention adopts a dual-drive traction device, which can not only pull the trolley to walk, effectively prevent the trolley from horizontal movement and jumping du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com