Anti-package metal drum of single rod and dual-wheels machine

A kind of mechanical and metal technology, applied in the field of mechanical drums for reverse roll rolling, can solve the problems of blind spots, residual air bubbles, and rolling impression embryos in rolling, so as to achieve the effect of no residual bubbles, shallow impressions, and ensuring molding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

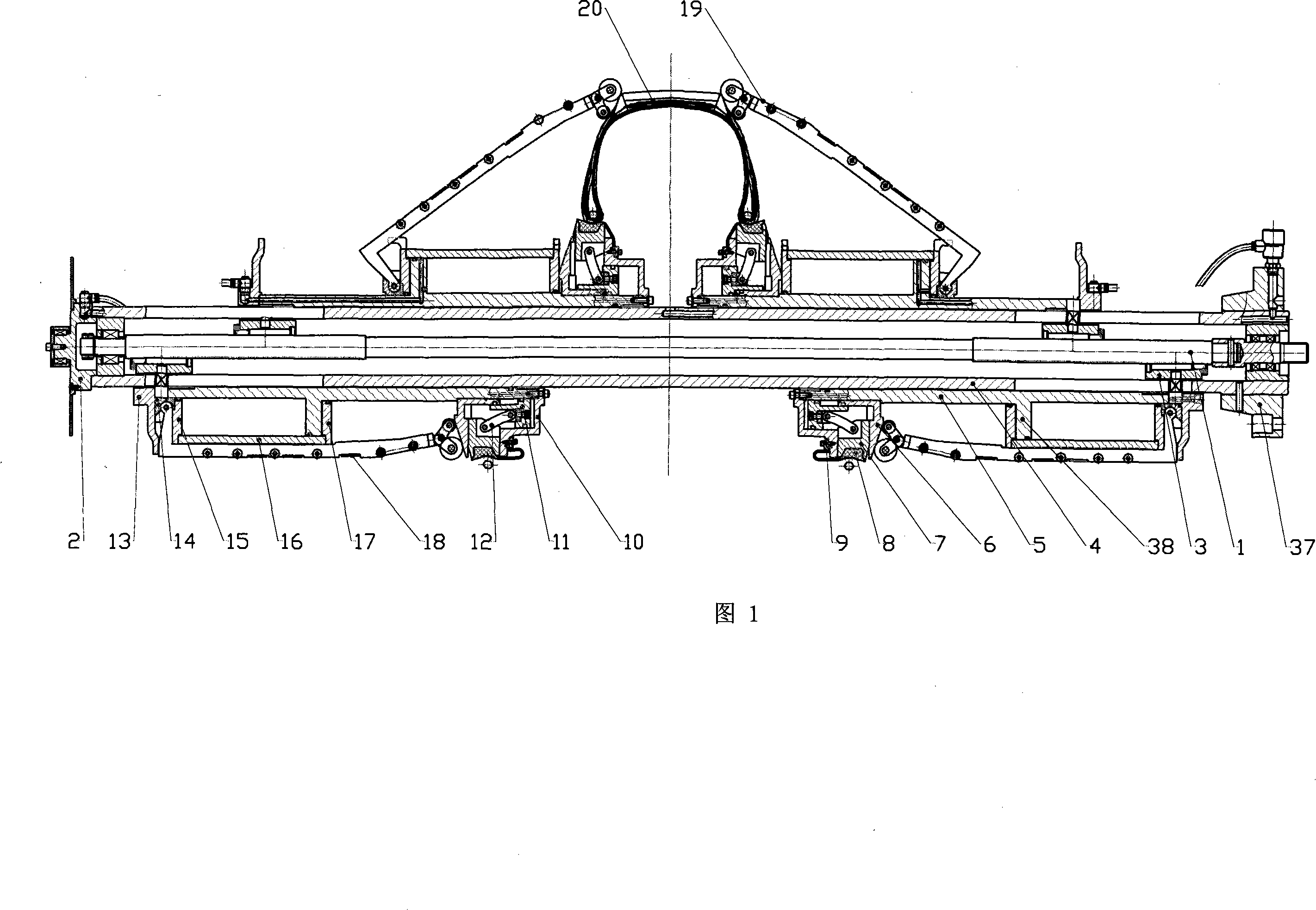

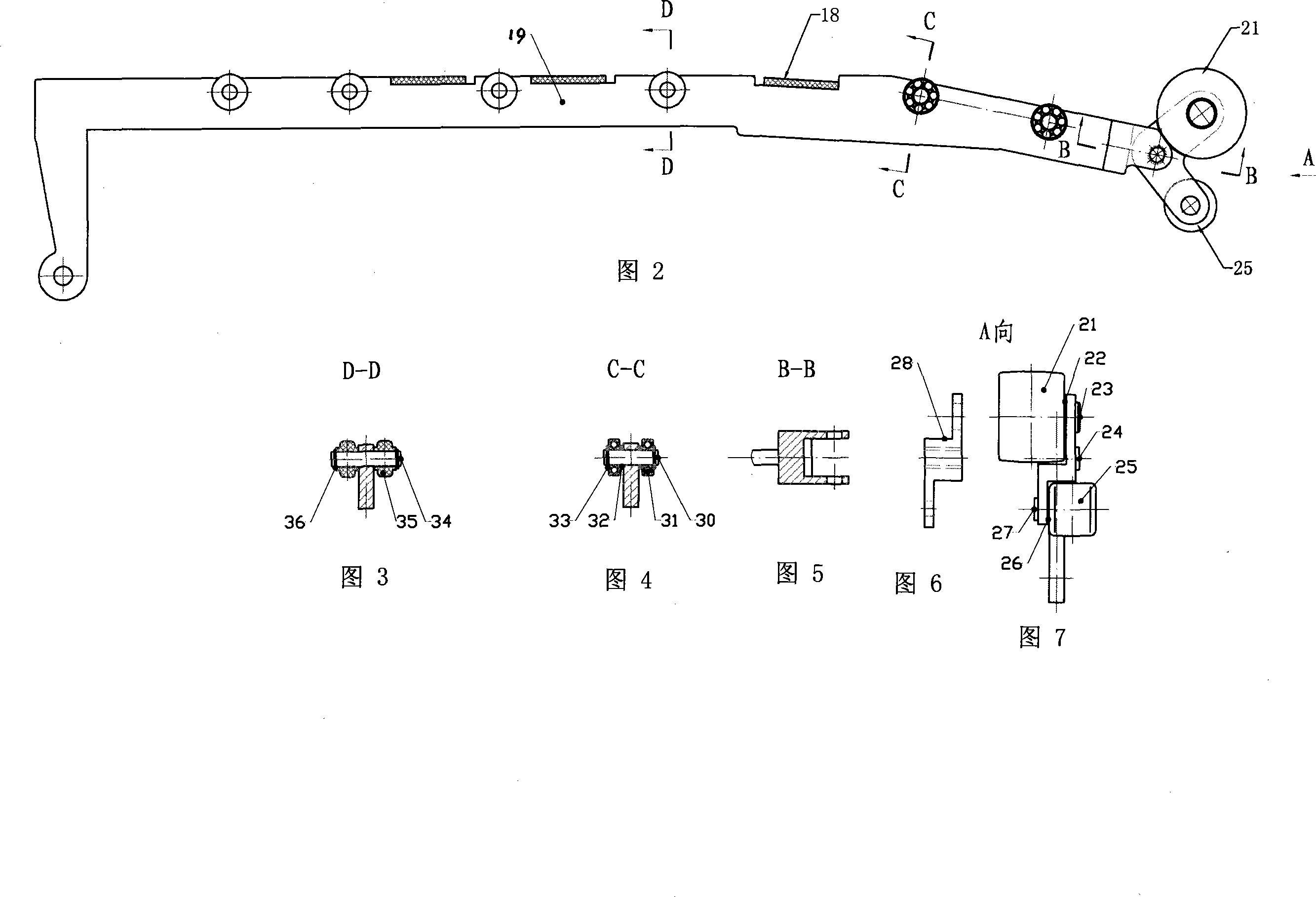

[0017] Referring to Fig. 1-Fig. 7, the single-rod double-wheel mechanical turn-up metal drum is mainly composed of a main shaft device and two side drums symmetrically arranged left and right on the main shaft. The main shaft device includes a hollow main shaft 4, a flange 37 and an end cover 2. Inside the hollow main shaft, there are left and right helical screw transmission pairs 1, and two nut sleeves 3 are arranged symmetrically on the left and right helical screws. Each nut The sleeve 3 passes through the chute on the hollow main shaft 4 and is connected with the corresponding side drum through a pin key. Each side drum includes an axle sleeve 5 sleeved on the hollow main shaft 4 and a group (for example, 30-40 pieces, which can be increased or decreased depending on the tire specification) evenly radially distributed turn-up rods 19, on the turn-up rods 19 The waist of the waist is provided with 3 elastic rubber rings 18, and the elastic rubber rings 18 are looped on all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com