Method and apparatus for controlling rotary machines

A technology of rotating parts and controllers, used in mechanical equipment, control of mechanical energy, control of generators, etc., can solve problems such as air gap size reduction, unbalance, rotor deflection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

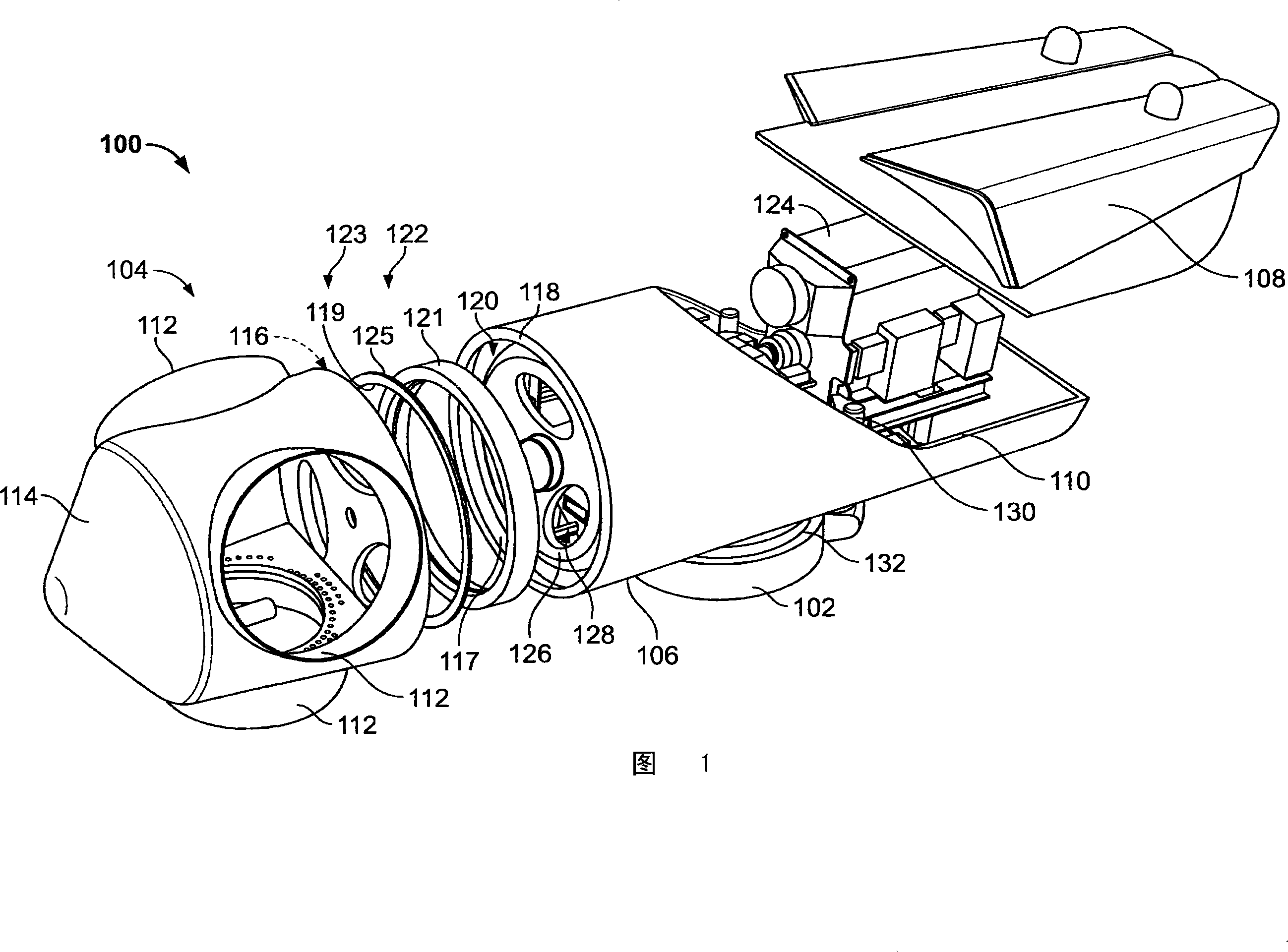

[0012] FIG. 1 is a simplified exploded view of an exemplary wind turbine generator 100 . In the exemplary embodiment, wind turbine generator 100 is a wind turbine having a horizontal axis. Alternatively, wind turbine 100 may be a wind turbine having a vertical axis. Also, alternatively, wind turbine 100 may be a 1.5 megawatt (MW) series or a 2.5 MW series wind turbine commercially available from General Electric Company of Schenectady, New York. dynamo. Alternatively, wind turbine 100 may be any wind turbine generator incorporating the invention described herein. Wind turbine 100 includes a fixture 102 extending from a tower or support surface (neither shown in FIG. 1 ). Where a tower is used, the height of the tower should be selected according to factors and conditions known in the art. Wind turbine 100 also includes hub assembly 104 , housing 106 , cover assembly 108 , and main frame 110 . Housing 106 is fixedly attached (also referred to herein as coupled or coupled) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com