8k line scanning lens

A scanning lens and k-line technology, applied in the field of online scanning lens, can solve the problems of low image precision, large color difference, easy image distortion, etc., and achieve the effect of improving the detection quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

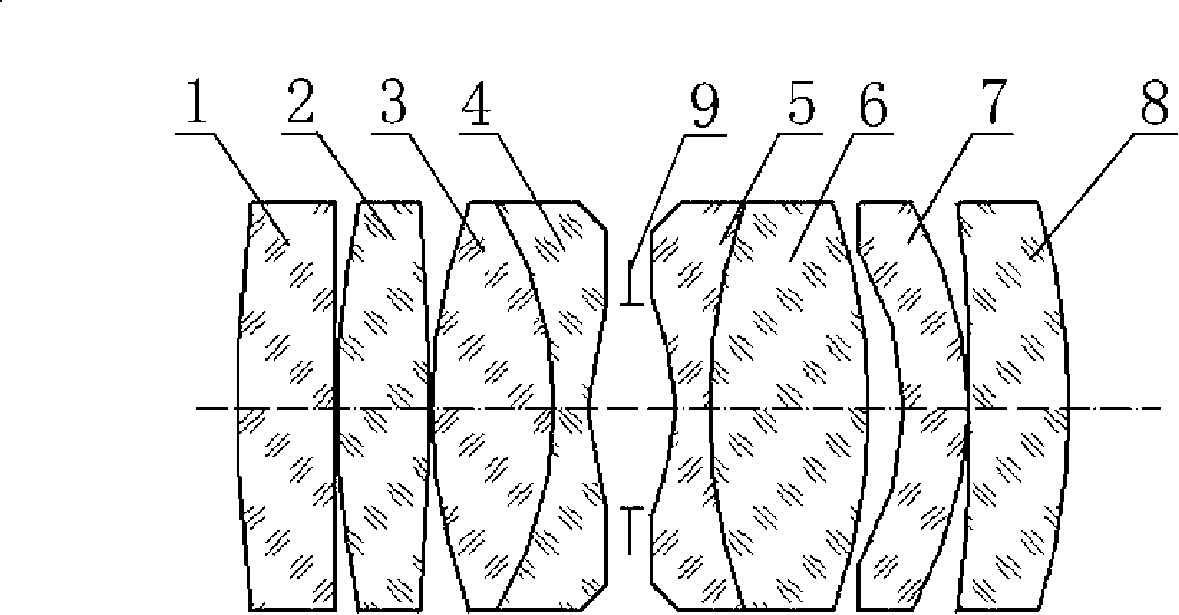

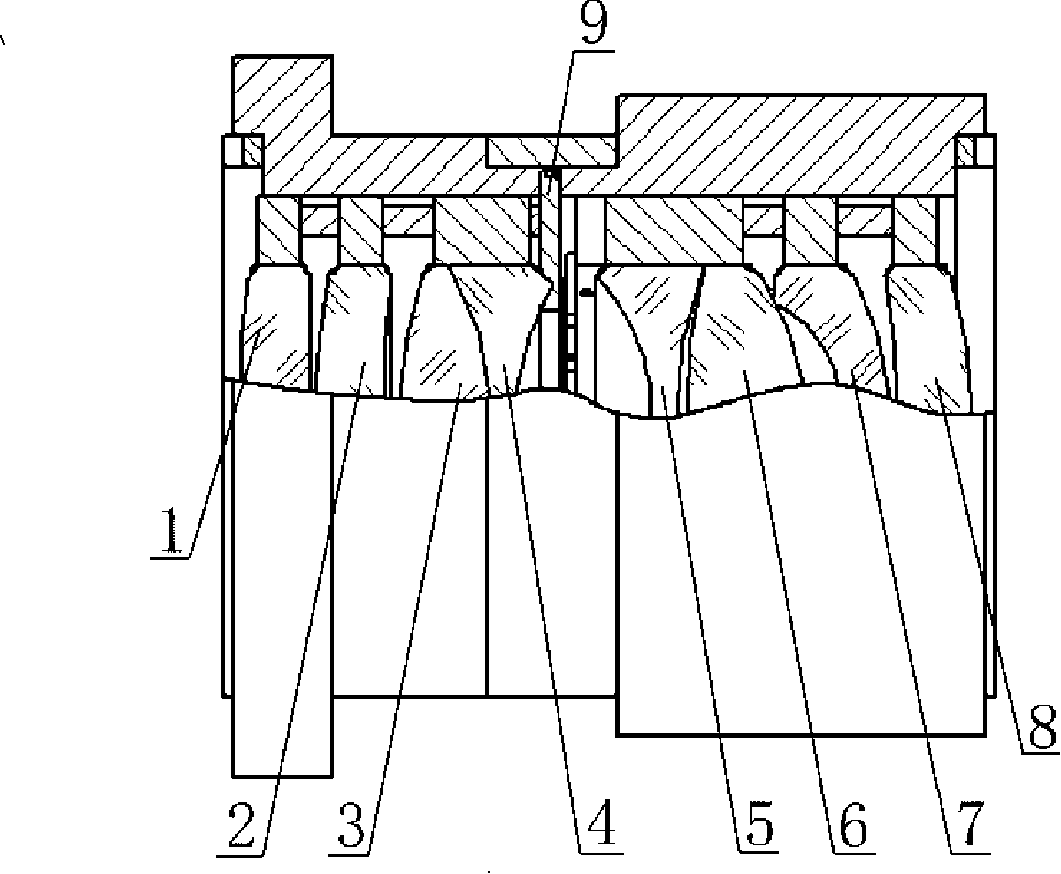

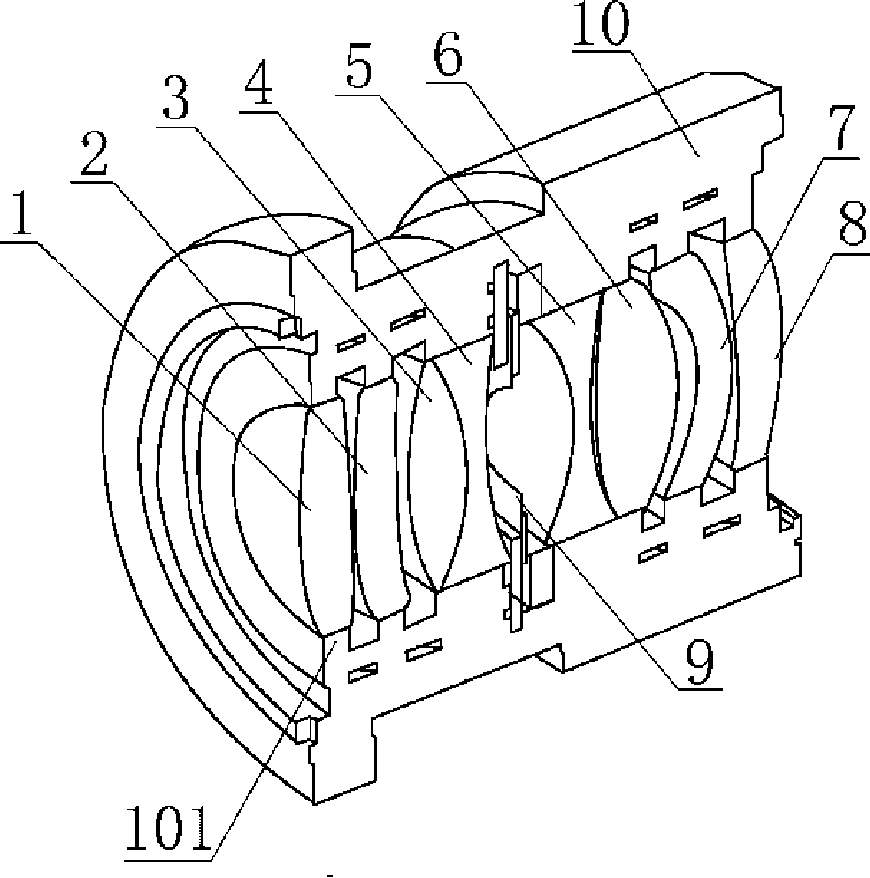

[0023] Examples see figure 1 , figure 2 , image 3 As shown, this 8k line scan lens includes a lens barrel 10 and a variable diaphragm 9 and a plurality of mirrors that are linearly combined in the lens barrel 10, and is characterized in that: from the object space to the image space, the lens barrel In 10, the first convex-concave lens 1, the second convex-concave lens 2, the first biconvex lens 3 and the glued part of the first biconcave lens 4, the variable diaphragm 9, the second biconcave lens 5 and the second biconcave lens 5 are fixed in sequence. A glued piece of convex lens 6 , a first concave-convex lens 7 , and a second concave-convex lens 8 .

[0024] A plurality of annular bosses 101 for fixing the lenses are distributed on the inner wall of the lens barrel 10 .

[0025] The working process of the present invention: the present invention is used in the visible spectrum range, and the chromatic aberration needs to be strictly corrected. At the same time, in vie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com