Linkage wood clapper structure

A stepping plate and linkage technology, which is applied to the arrangement of steps or ladders, fire rescue, transportation and packaging, etc., can solve the problems of excessive time-consuming, time-wasting, unreasonable, etc., and achieve the effect of saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

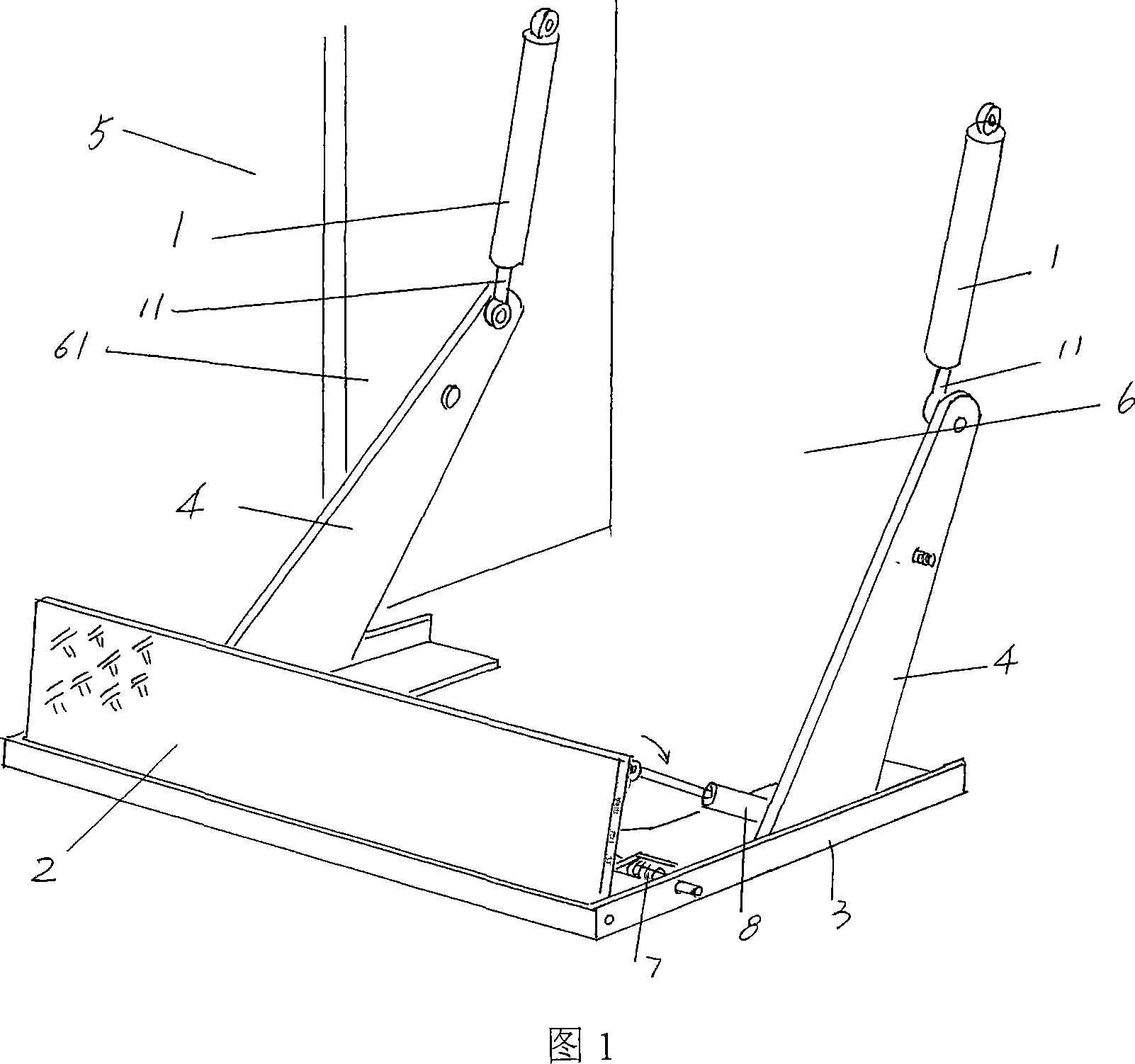

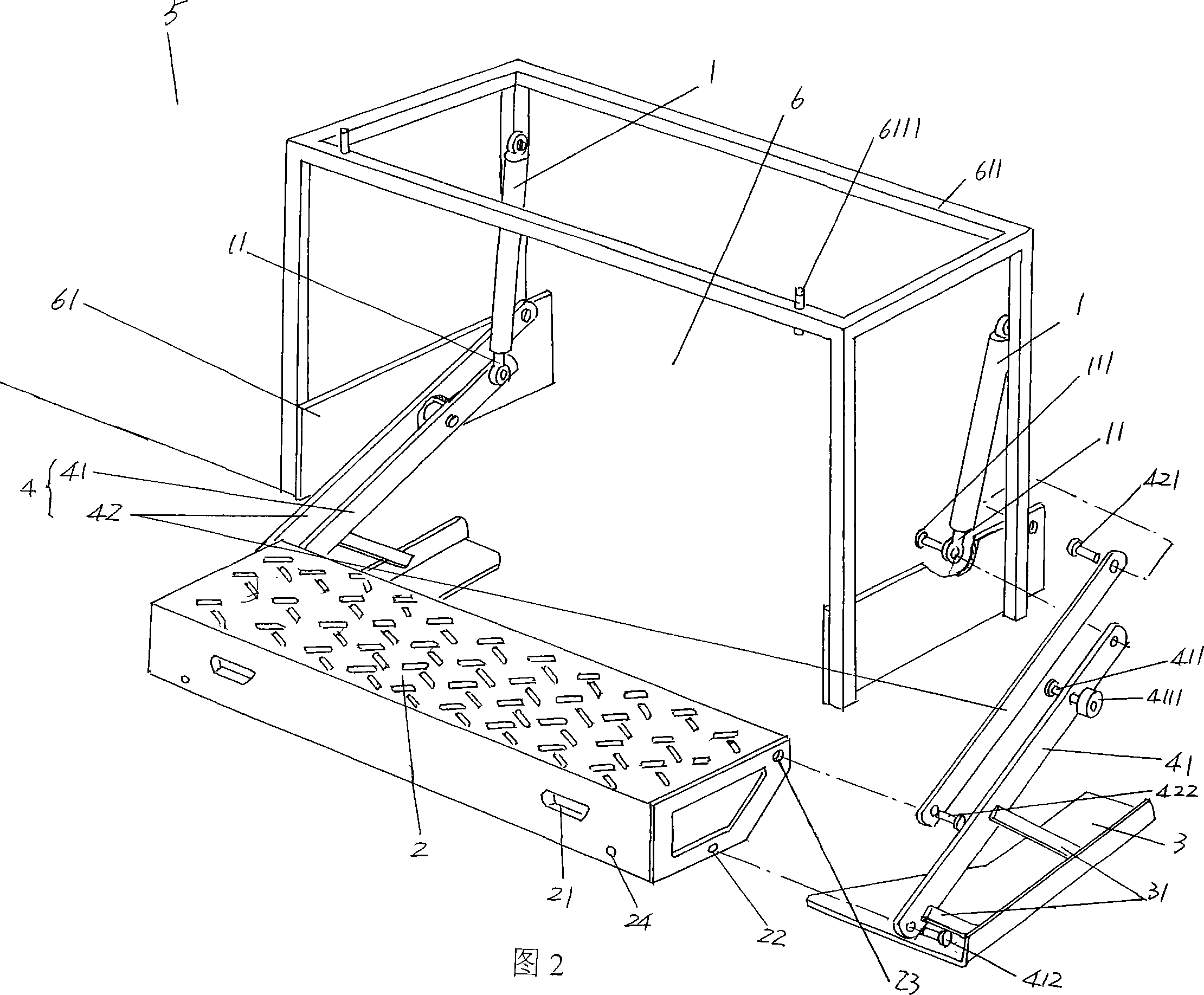

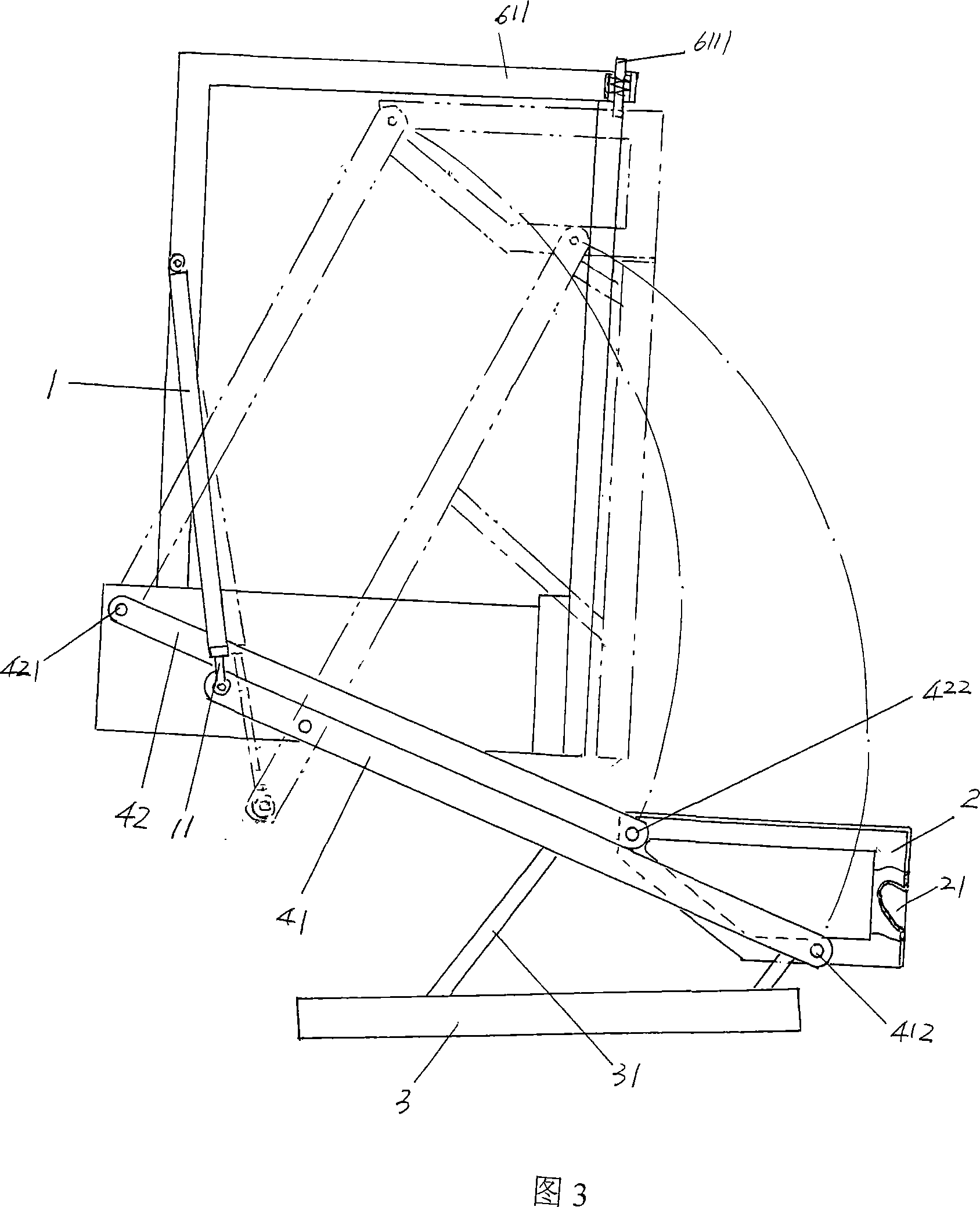

[0013] Referring to Fig. 2, a pair of wall plates 61 corresponding to the two sides of the rear wheel cavity 6 of the fire engine are provided, and the wall plates 61 are fixed on the bracket 611. It goes without saying that the space formed by the bracket 611 is Room for the rear wheels of the fire truck. The cylinder bodies of a pair of gas spring cylinders 1 are respectively connected to the upper parts of the two ends of the rear side of the bracket 611, and the cylinder posts 11 of a pair of gas spring cylinders 1 are respectively connected by pin shafts 111 to the first pins of the corresponding group of linkages 4. The front end of a connecting rod 41 is the upper end shown in the figure and is hingedly connected, and the rear end of the first connecting rod 41 is the lower end shown in the figure. hinged. In order to prevent any mutual interference between the first and second connecting rods 41, 42, a rotating shaft 411 is arranged at the front end of the first conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com