Multiheaded full-automatic wire winder

A fully automatic winding machine and winding mechanism technology, which is applied in coil manufacturing and other directions, can solve the problems of low winding speed, low degree of automation, and low efficiency, and achieve improved response time, stable control system, and accurate positioning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

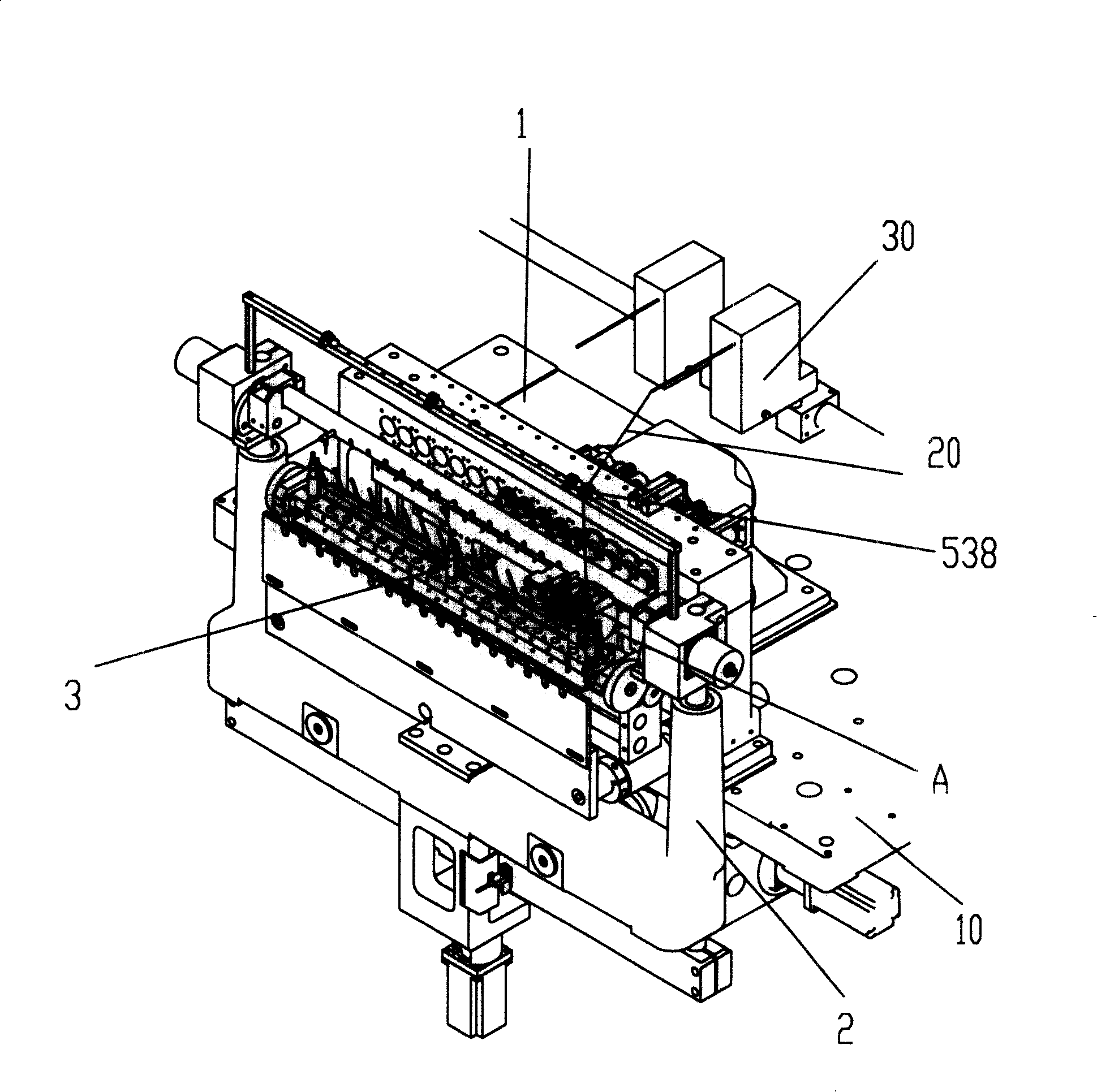

[0027] Such as figure 1 , figure 2 Shown, a kind of multi-head automatic winding machine of the present invention comprises:

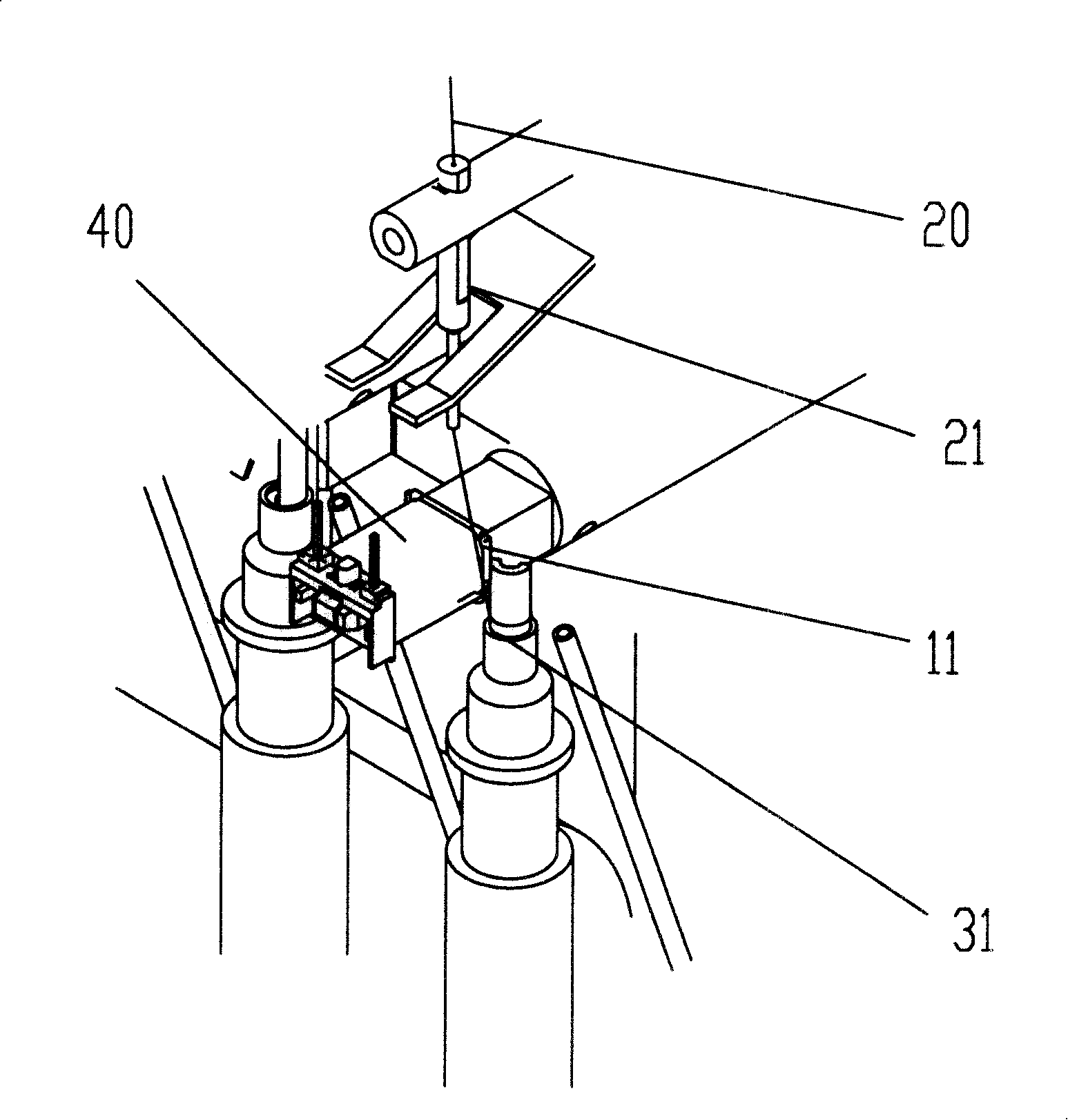

[0028] A seat body 10 for installing various mechanisms, on which a plurality of tensioners 30 for introducing enameled wire 20 are arranged side by side along the transverse direction;

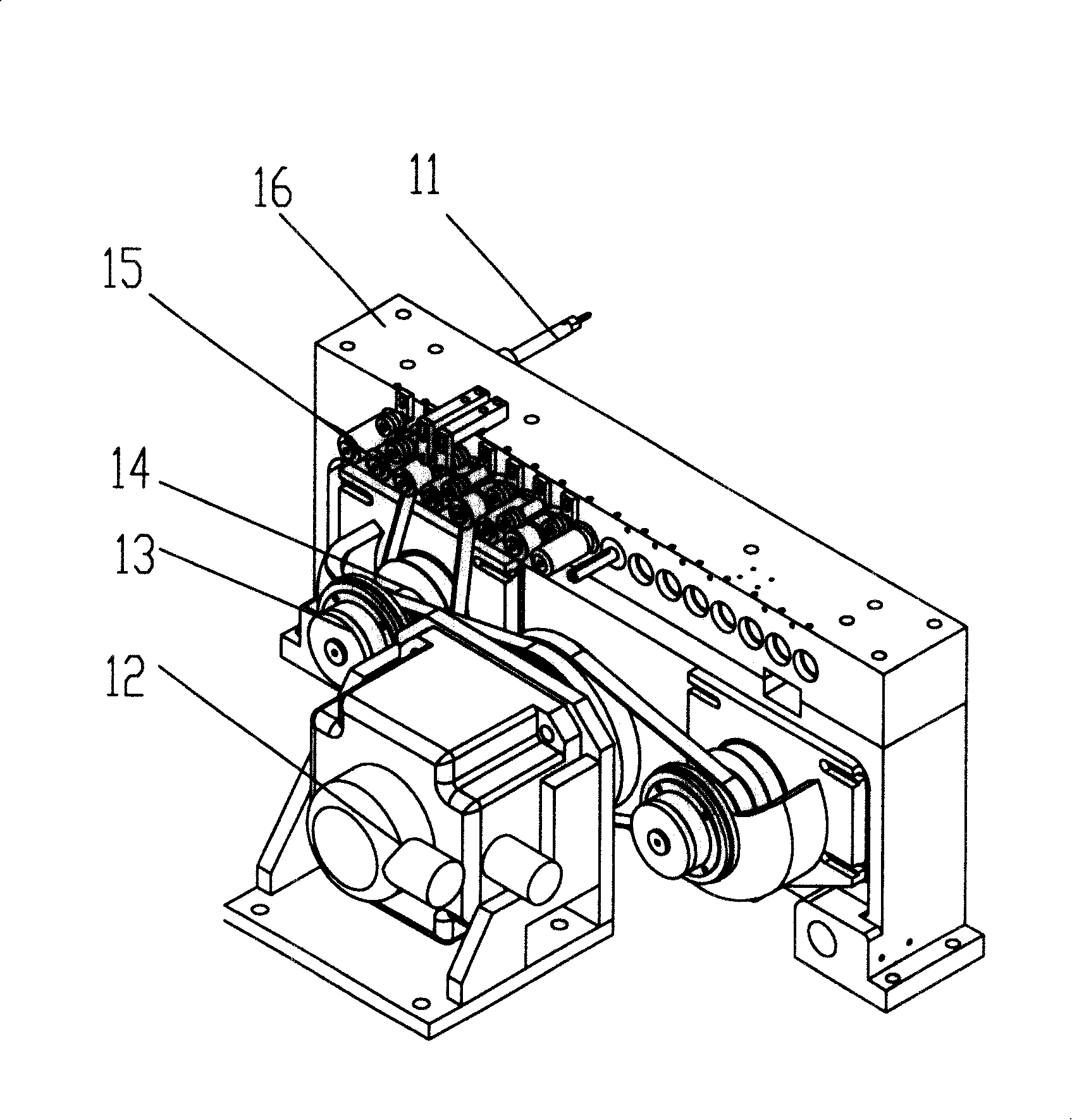

[0029] A main shaft winding mechanism 1 for driving the bobbin 40 to rotate to achieve winding is fixedly connected to the base 10. The main shaft winding mechanism 1 is provided with a plurality of main shafts 11 arranged side by side and driven synchronously by a main servo motor , the front end of the main shaft 11 is provided with a socket portion that can be loaded into the coil frame 40 in the longitudinal direction so that the coil frame rotates with the main shaft;

[0030]One can freely move horizontally, vertically and vertically to realize the X, Y, Z three-axis automatic winding mechanism 2 of the bobbin 40, which is fixed on the seat body 10 at the mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com