Electric actuator connected to a gearbox selector shaft by stepdown gearing

A technology of transmission mechanism and electric transmission, which is applied in the direction of electromechanical transmission, synchronous motor with rotating armature and stationary magnet, transmission control, etc. It can solve the problems of impact and vibration sensitivity, achieve high rotational torque and reduce clearance , the effect of reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

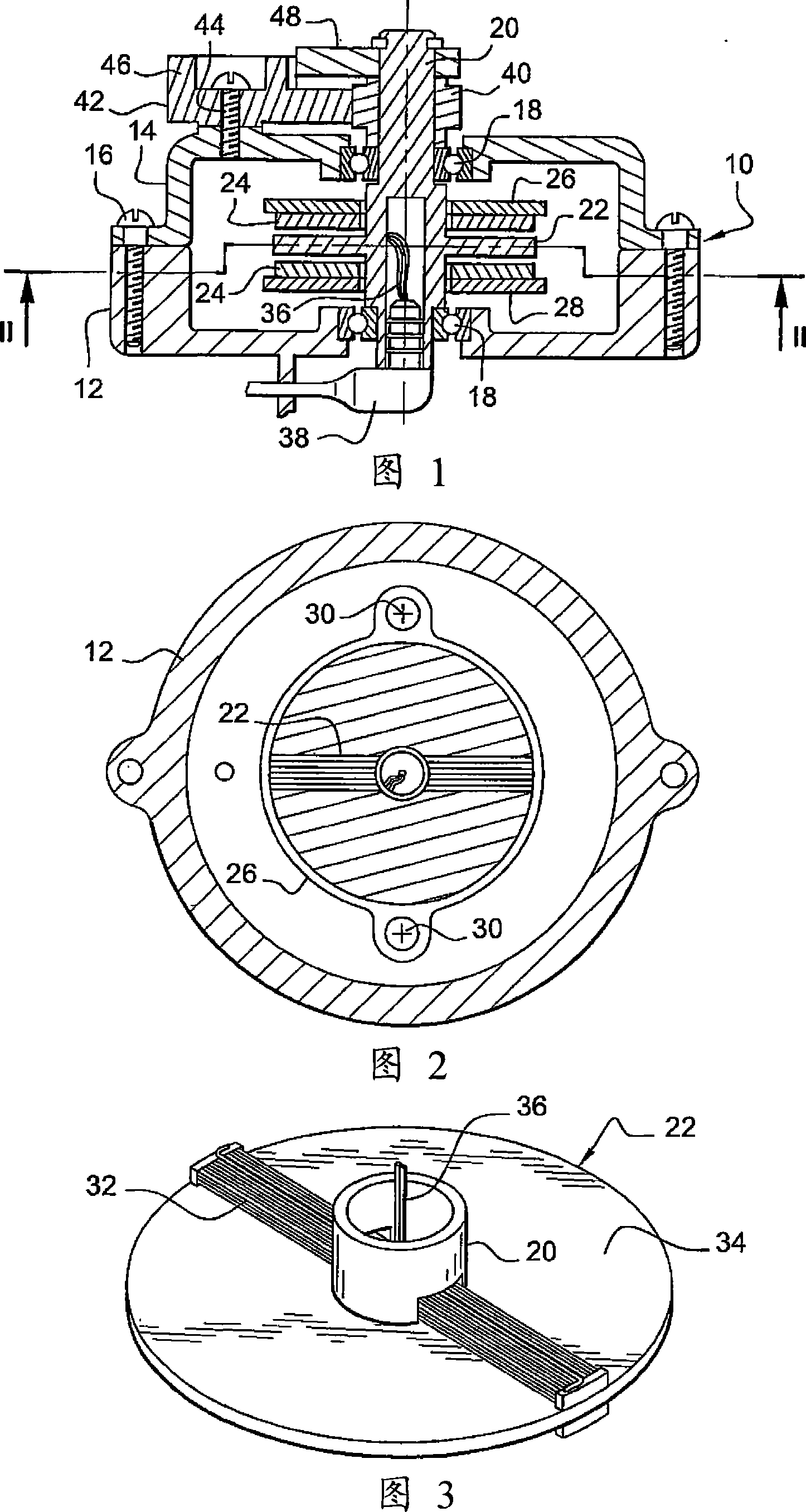

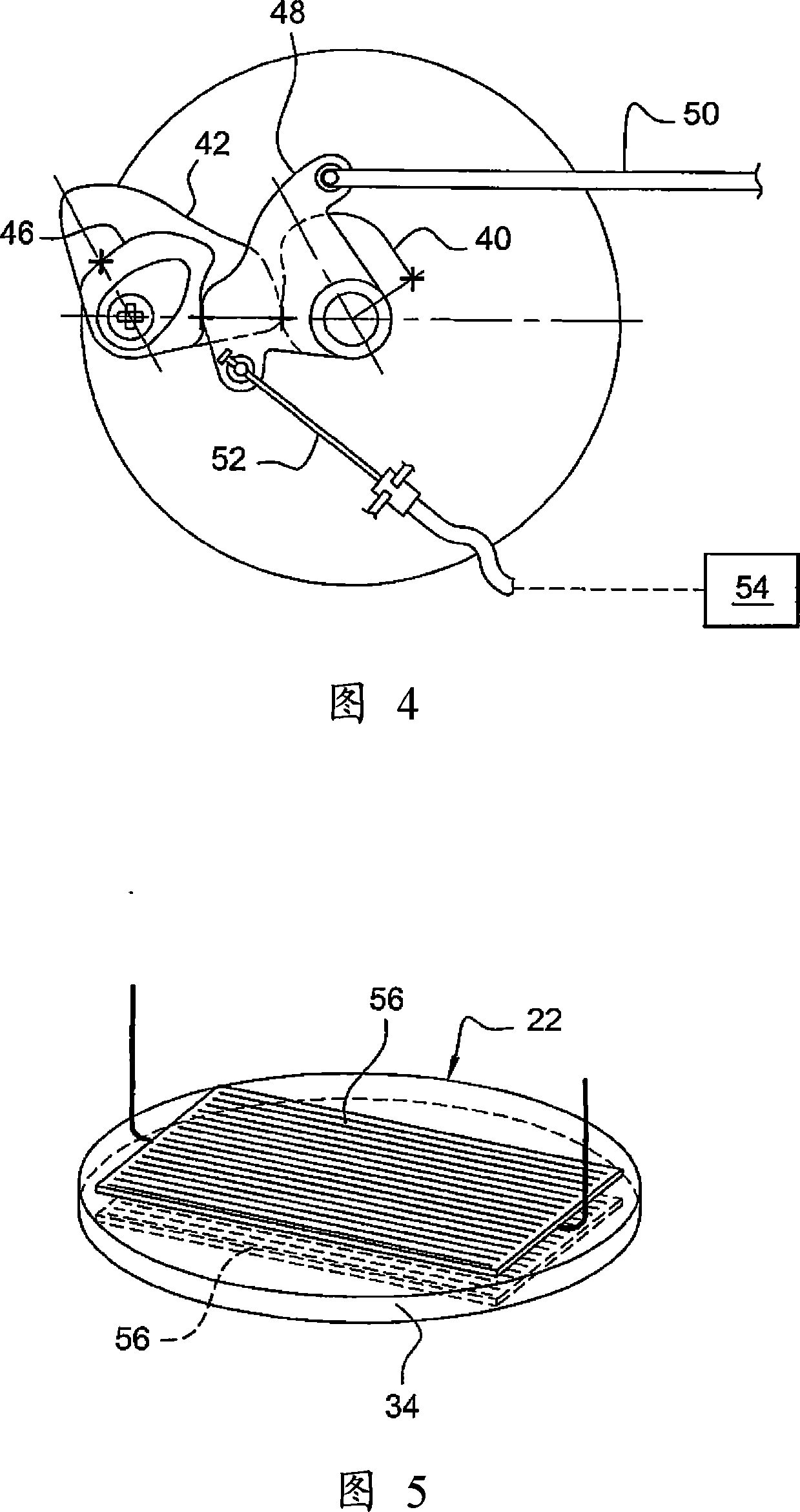

[0030] The electric transmission mechanism shown in FIG. 1 mainly includes a housing 10 composed of a base 12 . The base 12 has a cover 14 positioned thereon and fastened with screws 16 . The base 12 and the cover 14 respectively have central holes for mounting bearings such as ball bearings 18 . The bearings serve to center the shaft 20 and guide its rotation. The rotating shaft 20 constitutes a support for the coil 22 and an output member of the transmission mechanism.

[0031] The coil 22 carried by the rotating shaft 20 is introduced to rotate between two flat permanent magnets 24, one of which is fastened to the inner surface of the top plate 26 of the magnetic yoke, and the other flat permanent magnet is fastened to the inner surface of the magnetic yoke. the upper surface of the bottom plate 28 .

[0032] The two plates 26, 28 and the flat permanent magnet 24 are disc-shaped, each having a central hole for the shaft 20 to pass through. Two plates 26, 28 and the flat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com