Rib board pulling method

A rib and penetration technology, applied in the field of rib pull-in method, can solve the problems of increasing the welding workload, reducing the fatigue life of the hull structure, and reducing the material utilization rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0040] A rib drawing-in method, which comprises the following steps:

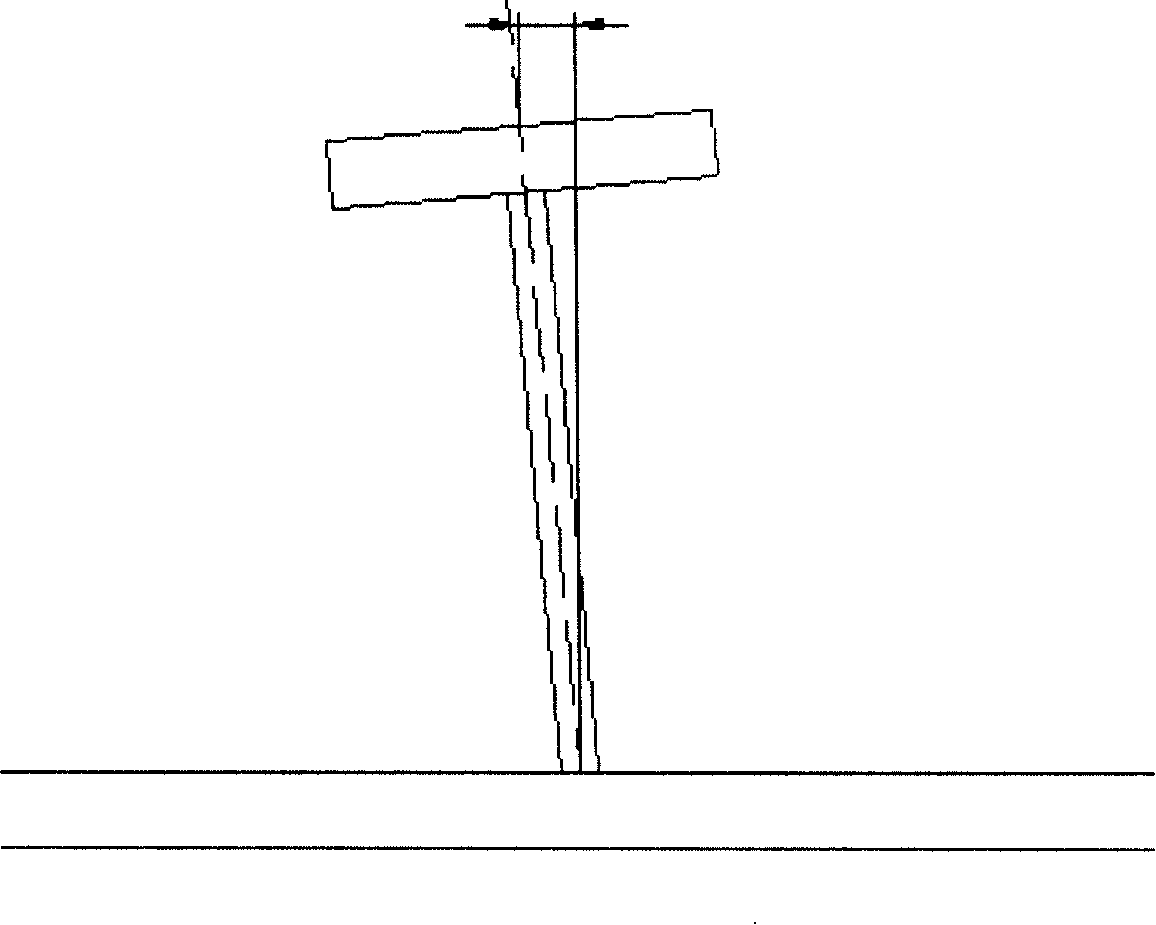

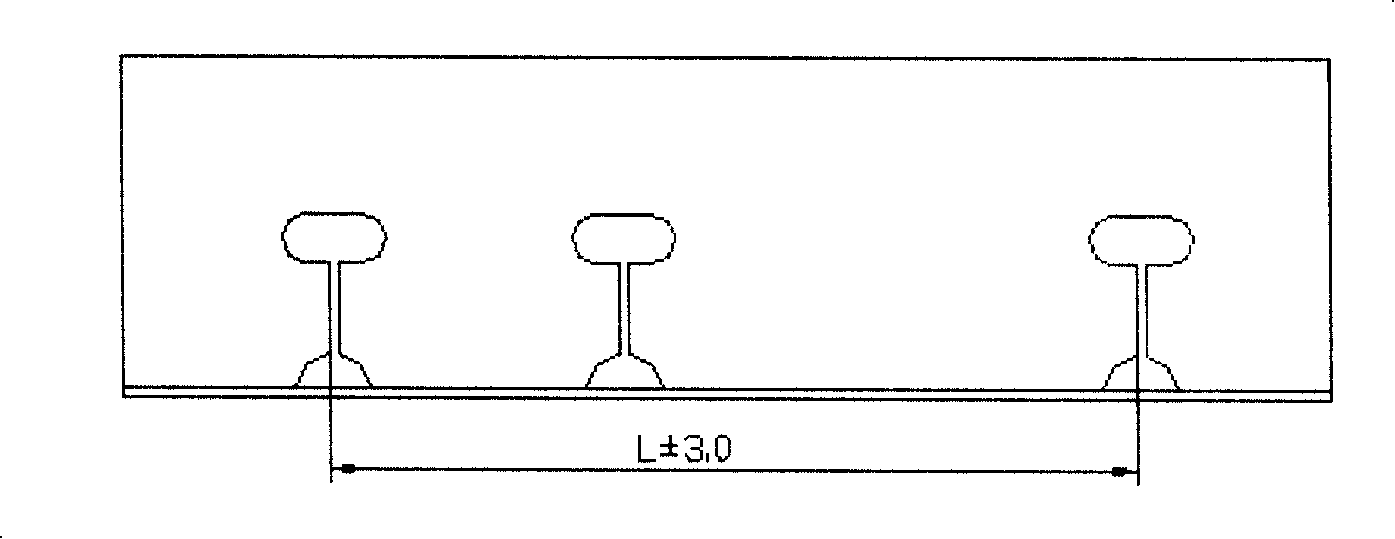

[0041] Cutting and fabrication of longitudinals; checking the installation line of longitudinals; checking the installation accuracy of longitudinals; checking the cutting accuracy of ribs; installing channel steel at the lower opening of ribs; inserting ribs into longitudinals;

[0042] The operation method and process requirements in each step are described in detail below.

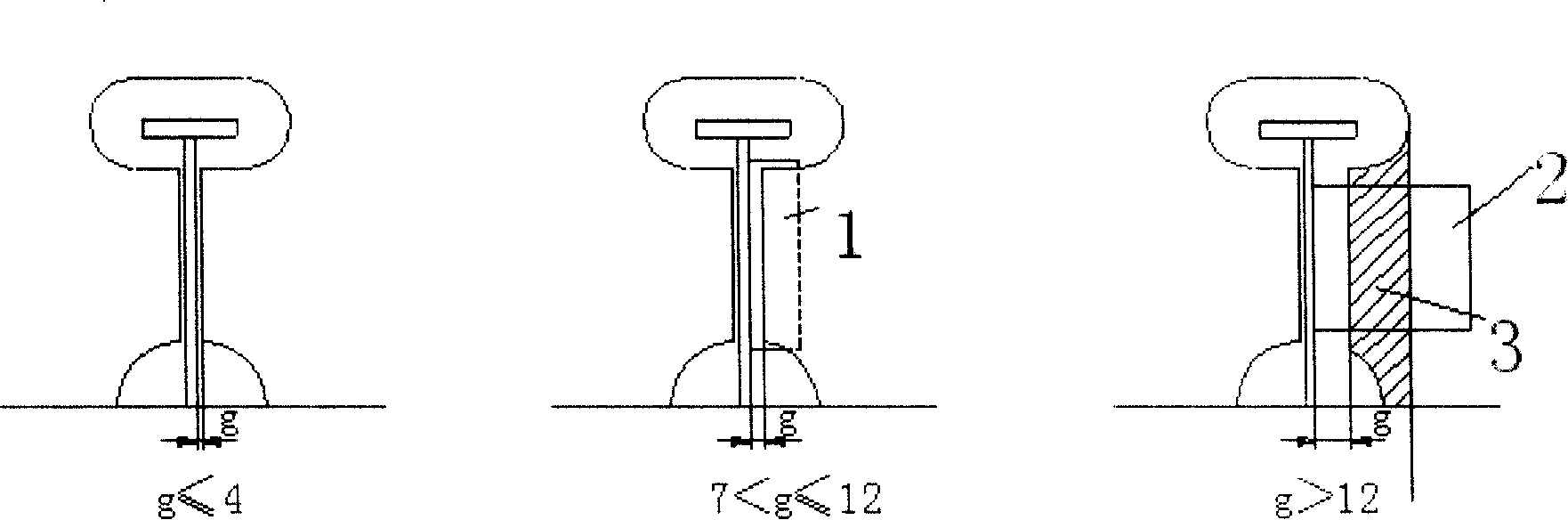

[0043] 1. Firstly, during the blanking and manufacturing process of the longitudinals, after the blanking of the web and face plate is completed, the free edge and end face of the face plate should be polished smooth. The precision criteria in this process are as follows:

[0044] Verticality between web and panel: ≤±2.0mm( Figure 5 shown) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Verticality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com