Electrodialysis reversal and electrochemical wastewater treatment method of compound containing nitrogen

A technology of reverse electrodialysis and wastewater treatment, applied in the direction of osmosis/dialysis water/sewage treatment, chemical instruments and methods, neutralization water/sewage treatment, etc., can solve the problems that are not suitable for removing ionic substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

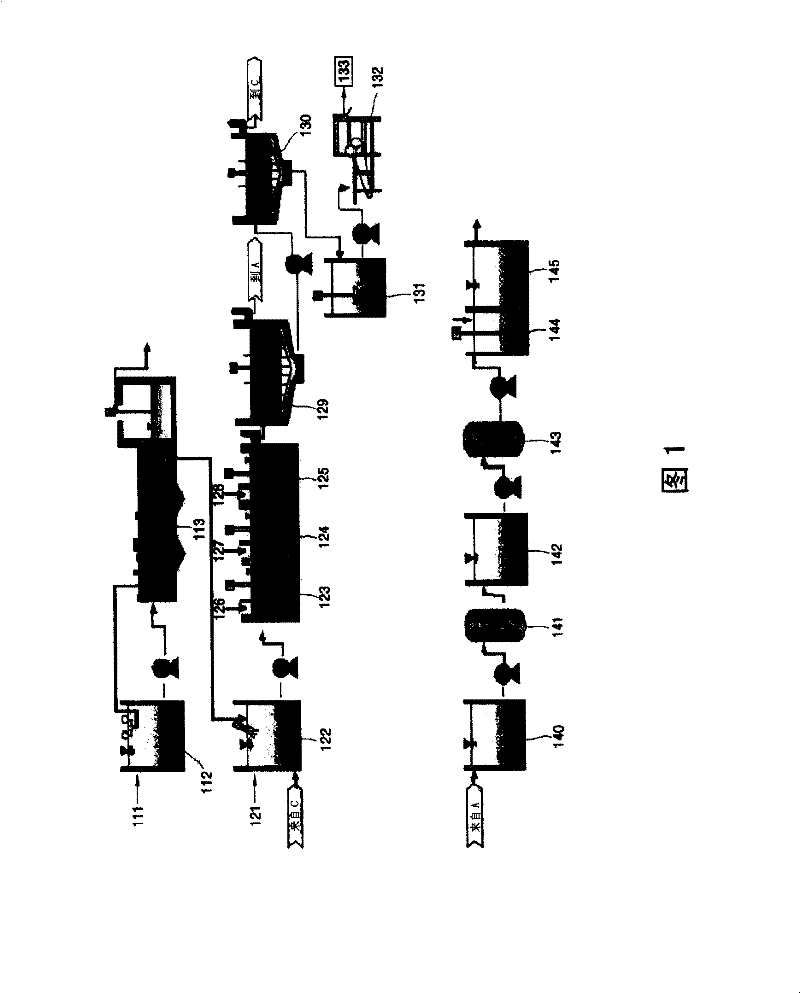

[0033] According to an embodiment of the present invention, the influent may have chemical oxygen demand (COD) and total nitrogen (T-N) derived from ethanolamine (ETA).

[0034] The reverse electrodialysis (EDR) process can be performed in the pH range of 4 to 7.

[0035] The EDR process may include reuse of product water discharged from the EDR device as industrial water.

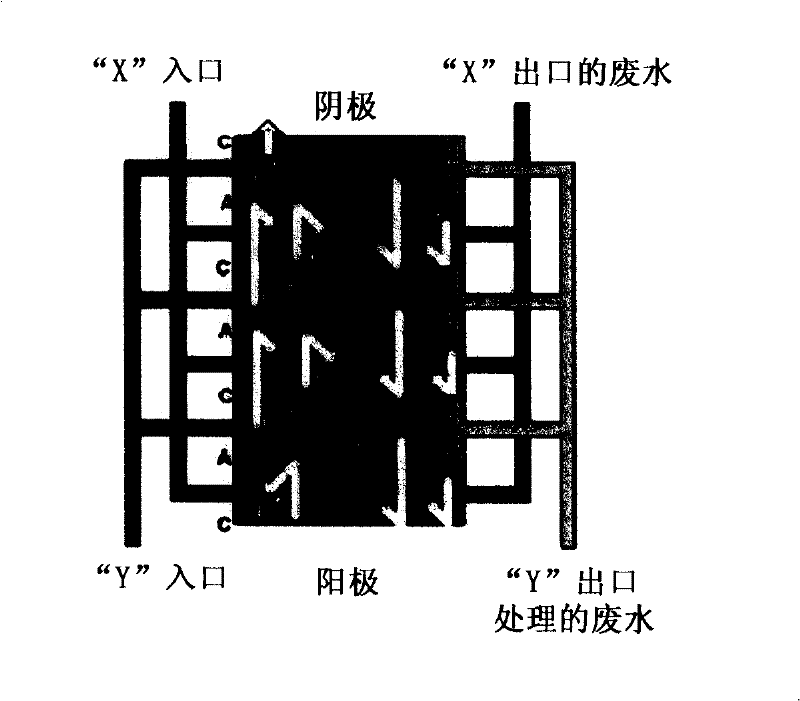

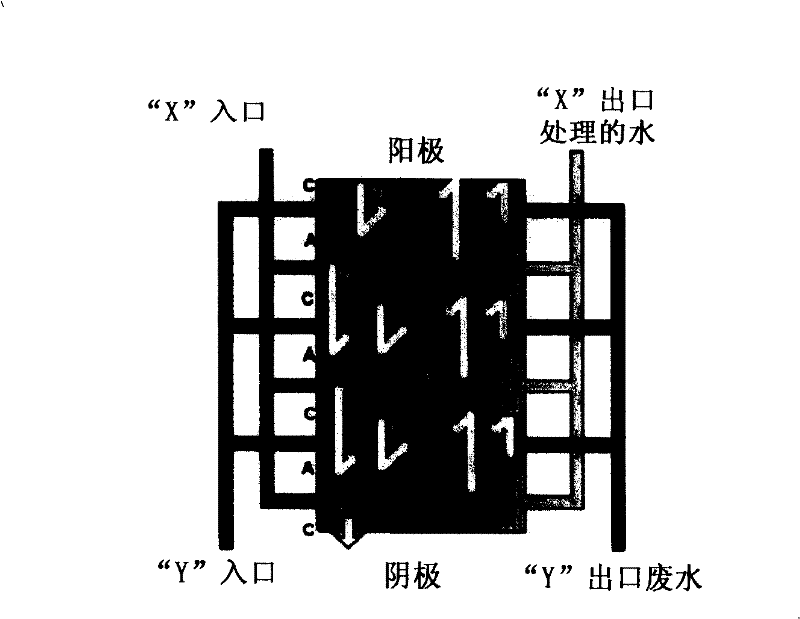

[0036] The EDR process can be operated by inversion.

[0037] The EDR process can be operated by out-of-specification product recycling (OSPR).

[0038] The EDR device can be equipped with a device for controlling the hydrogen ion concentration and / or the conductivity of the concentrated water.

[0039] The EDR process may include: after adding Cl-containing salt or seawater, the concentrated water flows into the EWT equipment.

[0040] The bipolar reactor can be used as the reactor of the EWT plant.

[0041] The spacing between the electrodes in the bipolar reactor can be 10 to 30 mm.

[0042] The current density of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com