Method and device for detecting pollution degree of lubricating oil

A technology of pollution degree and lubricating oil, applied in measuring devices, material inspection products, image data processing, etc., can solve the problems of difficulty in accurately measuring diameter and area, poor measurement accuracy, inconvenient management, etc., to save cumbersome The effect of working, high measurement accuracy and fast processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings.

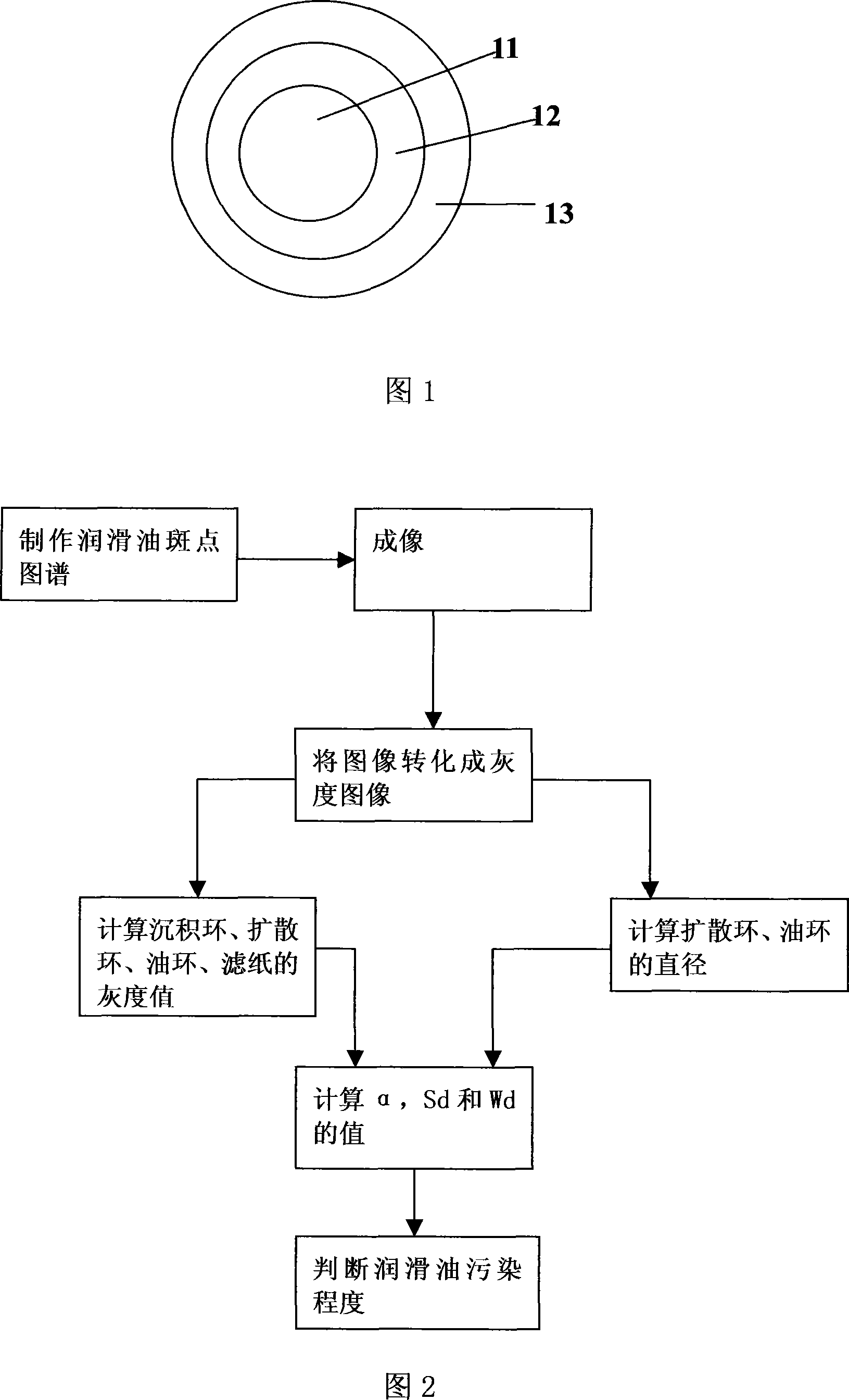

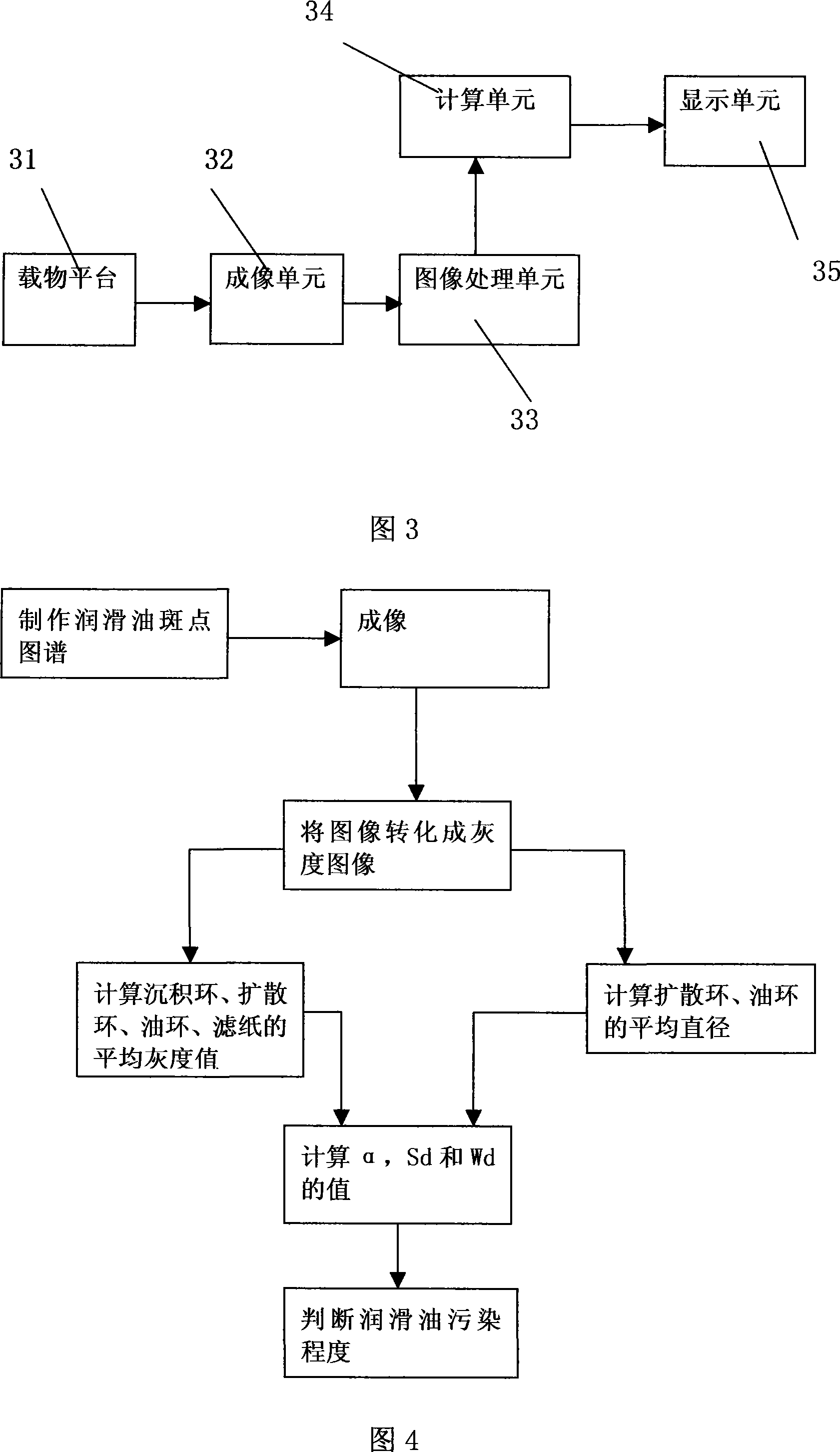

[0036] As shown in FIG. 2 , FIG. 3 , and FIG. 4 , the lubricating oil pollution degree detection device of the present invention includes an object loading platform 31 , an imaging unit 32 , an image processing unit 33 , a computing unit 34 and a display unit 35 . Place the prepared lubricating oil spots on the loading platform 31 , and turn on the transmission surface light source on the loading platform 31 . The imaging unit 32 uses a CCD camera to image the lubricating oil spots to obtain a lubricating oil spot map. The atlas is processed by the image processing unit 33, converted into a grayscale image, and the average grayscale value of the oil ring, the average grayscale value of the diffusion ring, the average grayscale value of the deposition ring, and the oil ring in the grayscale image are detected. The average diameter of the diffusion ring. The computing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com