Dynamic pressure flexible simulation ink making machine

A technology of dynamic pressure and ink grinding machine, which is applied in the direction of ink table, printing, office supplies, etc., can solve the problems that the flexible state of dynamic pressure cannot be realized, and the artificial ink grinding cannot be simulated, so as to achieve reliable force balance, freedom of choice, Avoid the effect of tilting and tilting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

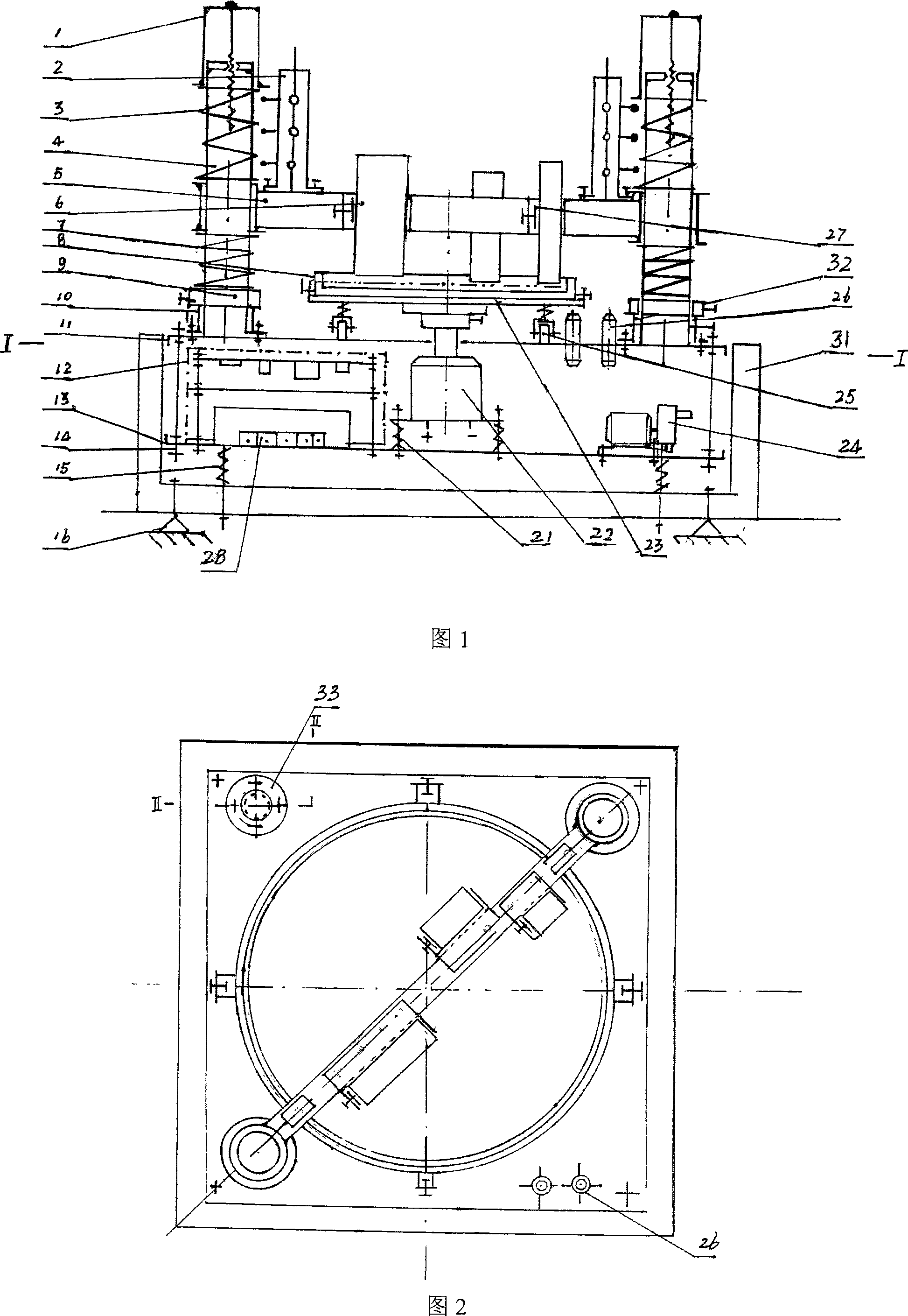

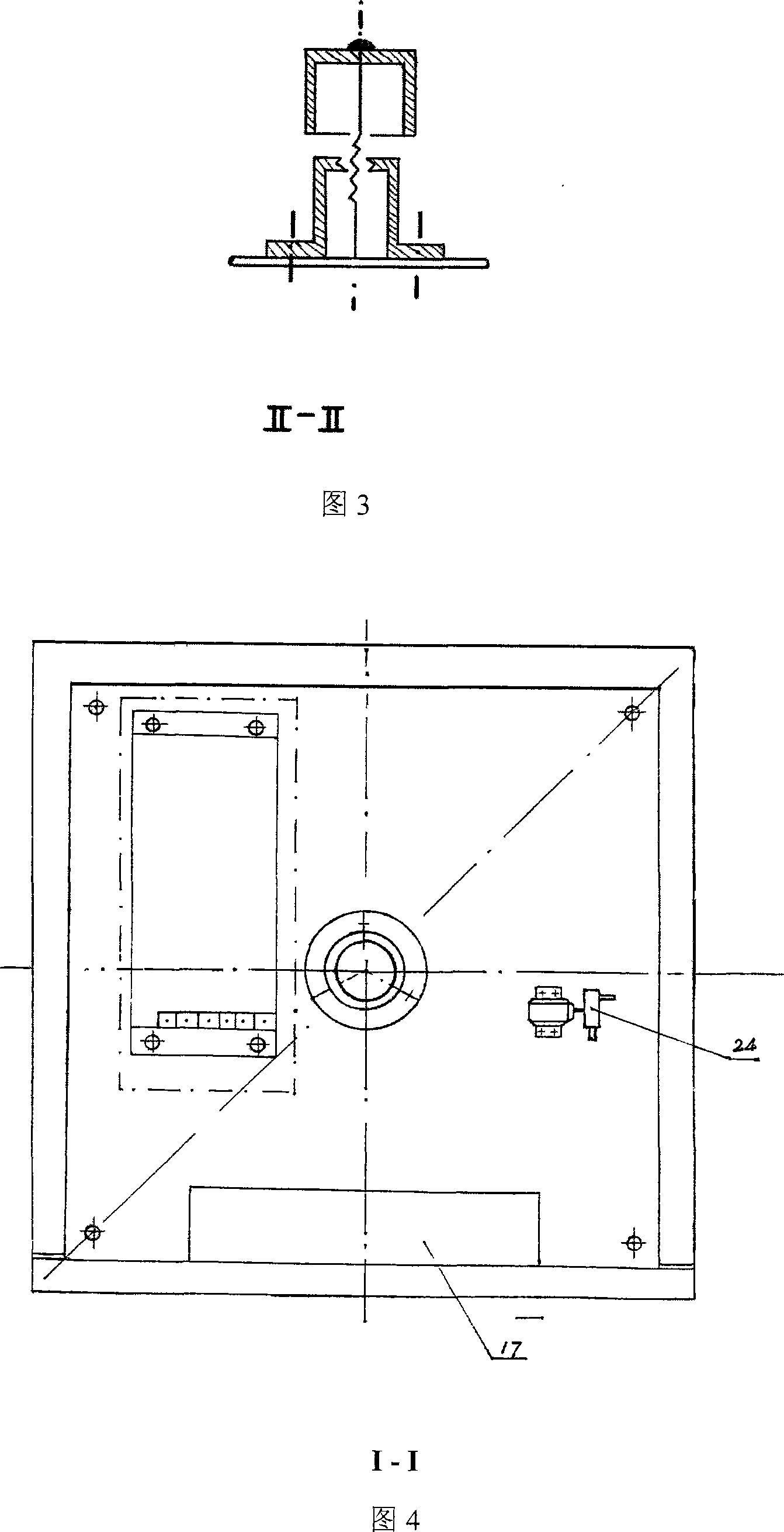

[0025] As shown in Figures 1-5, the flexible simulated ink grinder of the present invention is composed of a mechanical part driven by a motor and an electronic control part mainly composed of a single-chip microcomputer main control circuit to form the technical solution of the present invention.

[0026] The composition of the mechanical part:

[0027] It mainly consists of a rotatable guide shaft column 4, a guide shaft column base 10, a booster spring 3, a return spring 7, a tubular booster bolt (which can also be replaced by a miniature jack) 1, a portal beam with a guide sleeve 5, an inkstone 8, Top panel 11, lower bottom plate 13, motor 22, casing 31, ink suction pump 24 and ink suction pipe etc. constitute. The mechanical part also includes: the electronic pressure light mark 2 installed on the portal beam 5, the inkstone support plate 23, the elastic support wheel 25 connected with the inkstone support plate, the distance bolt 14 connecting the upper panel and the low...

Embodiment 2

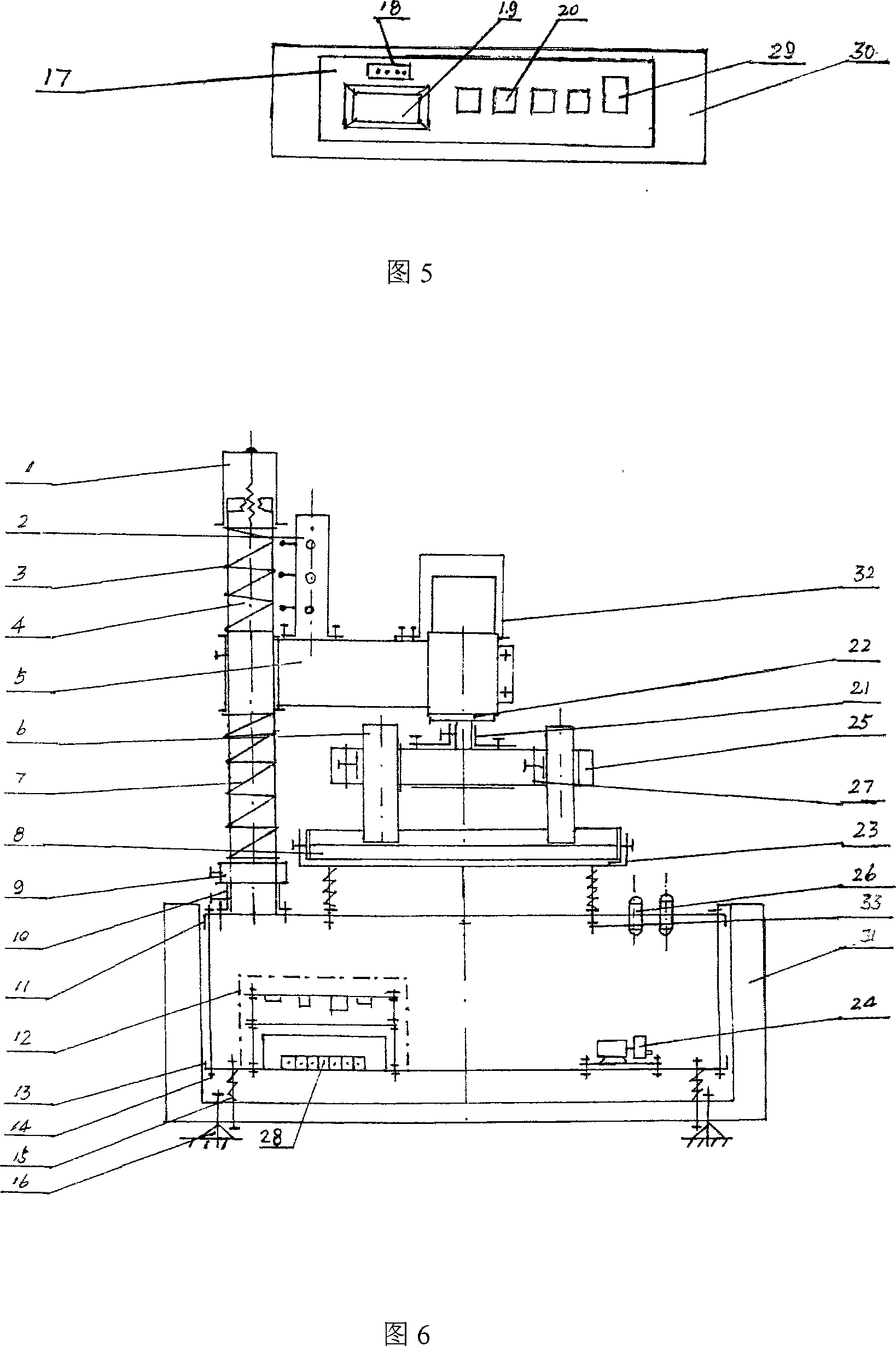

[0035] As shown in Figures 6-8, the main structure is basically the same as that of Embodiment 1, the difference is that the motor is placed on the top and the ink anchor rotates. The flexible imitation ink grinder. Structurally, a rotatable single-back motor cover 34 (cancellation of the portal beam), an inline motor shaft seat 35, a rotating beam 36, a motor cover 37, an inkstone tray spring bolt 38, etc., and an inline motor shaft seat 35 are installed. On the swivel beam 36, the ink clamping frame is also contained on the swivel beam, the motor housing 37, the connection spring bolt 38 of the inkstone tray and the panel 11. The electronic control circuit is the same as that of Embodiment 1.

[0036] The manual operation control when above-mentioned two embodiments work:

[0037] The machine is powered on, the red light on the keyboard is on, and the functional units of the main control board are in the pre-working state when they are powered on. The LCD screen displays th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com