Joint-cutting laminating machine for forest farmland

A mulching machine and slitting technology, which is applied to agricultural machinery and tools, shovels, plows, etc., can solve the problems of crops dying, manpower is difficult to complete, water and fertilizer absorption, etc., and the soil wall is smooth and tidy, supporting power is small, and the efficiency is improved. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

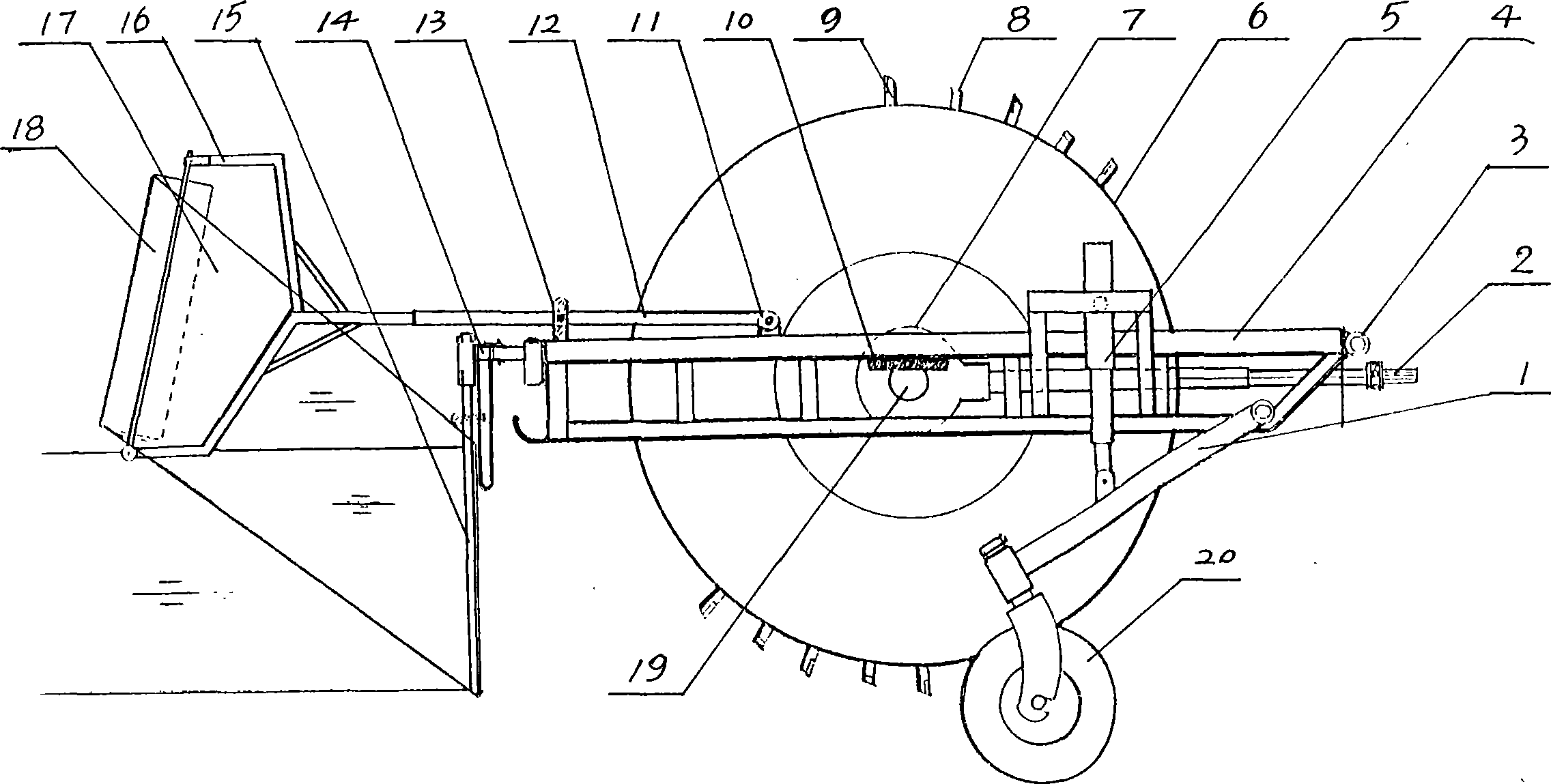

[0009] In the figure, the rectangular frame 4 is a double-layered rectangular frame, and a circular traction ring 3 is installed at its front end, in order to be connected with the power vehicle for traction. The upper middle part of the rectangular frame 4 is longitudinally installed with two beams. frame, the bottom surface of the beam frame is connected with the shaft mutual shell 10, and the slitting cutter head 6 is installed in cooperation with the bearing shell 10 through the slitting cutter head shaft 19 in the middle axial direction, so that the slitting cutter head 6 is positioned between the two beam frames. The middle part, and parallel to it; the gearbox 7 is fixedly installed on the rectangular frame 4 on one side of the slitting cutter head 6, and is connected with the slitting cutter head shaft 19 through its output shaft, and the input transmission shaft of the gearbox 7 is 2 directions Extend forward, connect with the power source in the tractor, and input pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com