Combination type hydraulic pressure reel cart

A hydraulic winch and combined technology, which is applied in hoisting devices, clockwork mechanisms, etc., can solve the problems of not being small and flexible enough, occupying a large area, and affecting the use effect, etc., to achieve reduced transmission space, low manufacturing cost, and easy installation. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

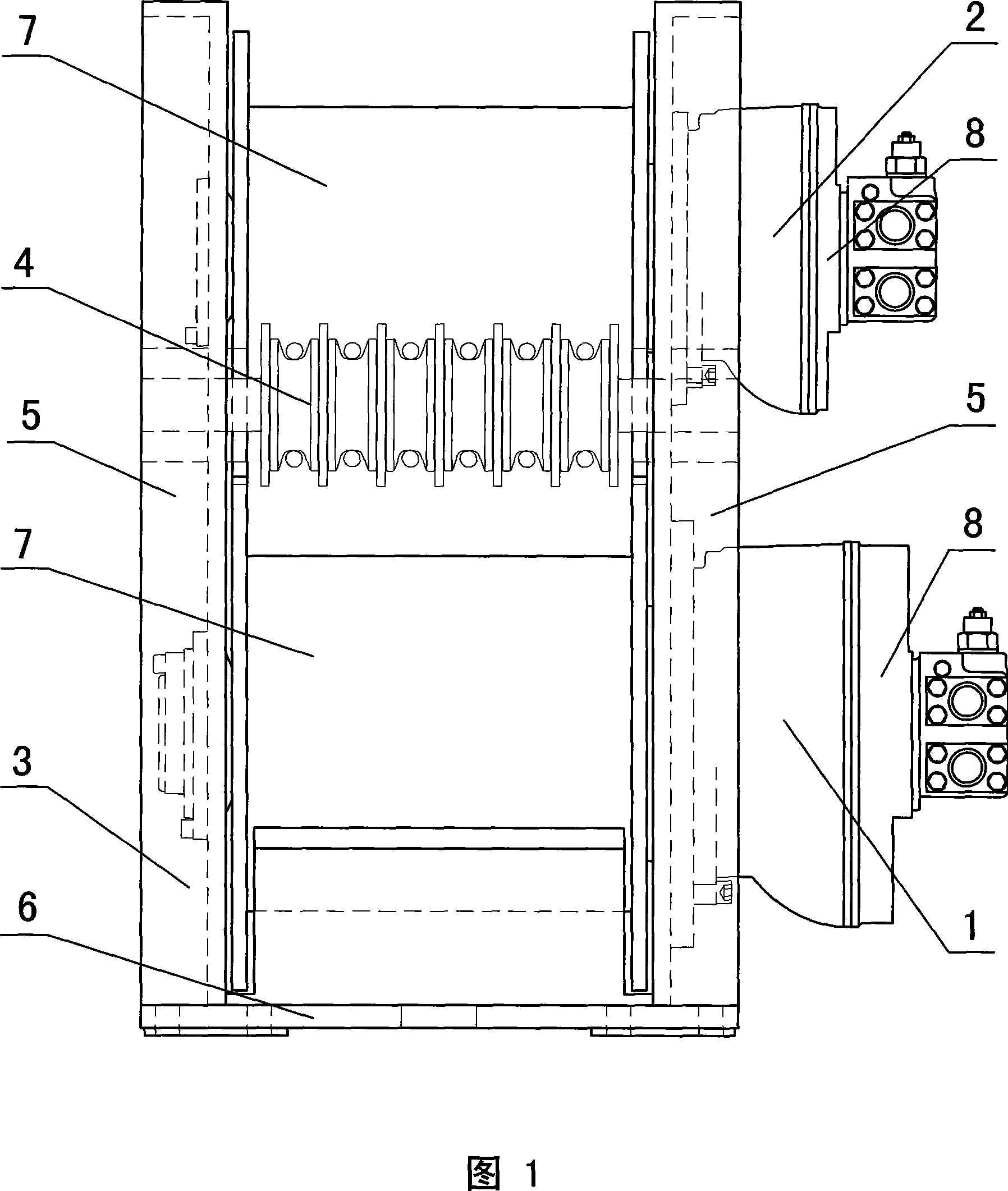

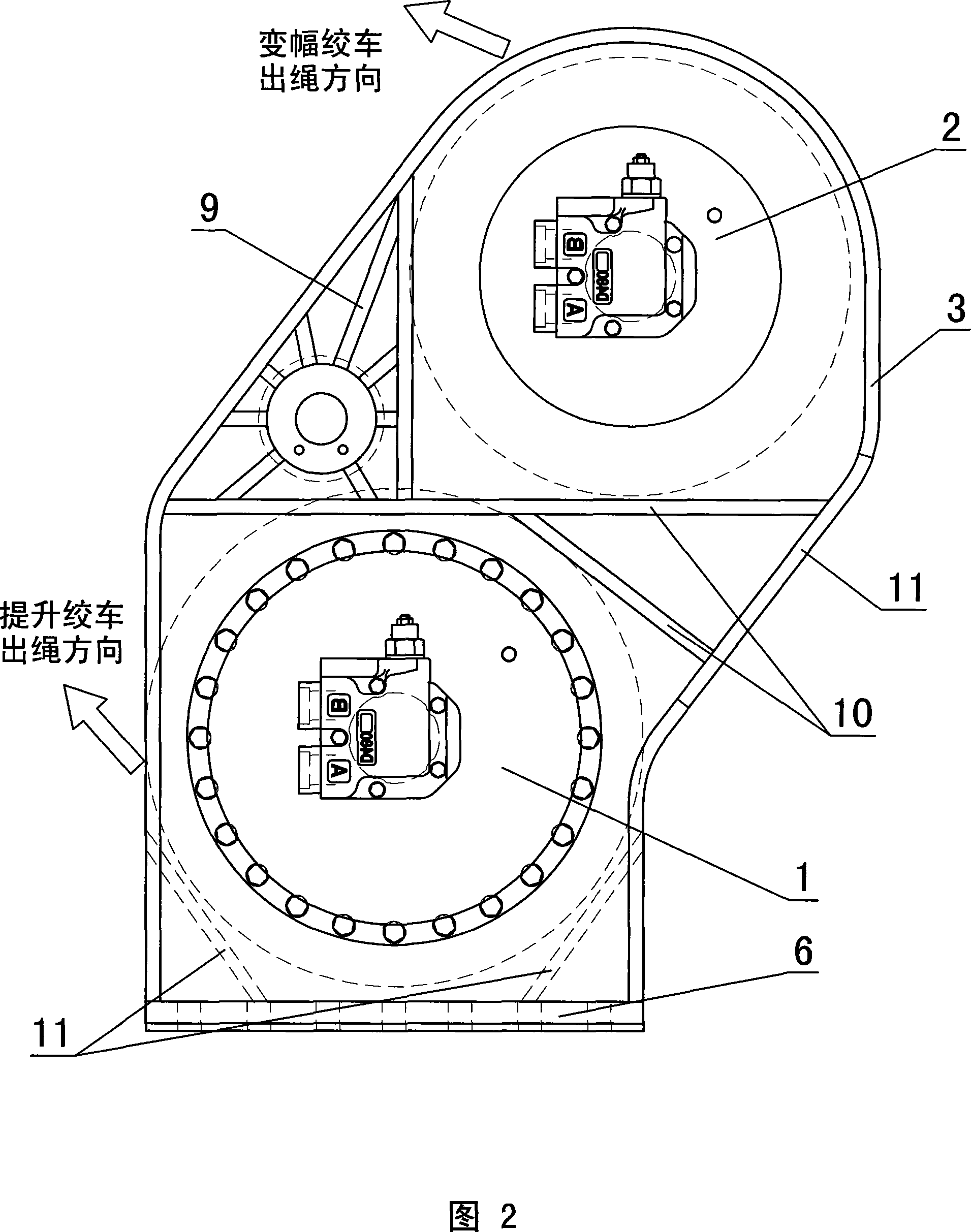

[0016] In the embodiment 1 shown in Figure 1 and Figure 2, the combined hydraulic winch is composed of a hoisting winch 1, a luffing winch 2, and a luffing fixed pulley block 4. The hoisting winch 1 is arranged in the lower half of the combined hydraulic winch , The luffing winch 2 is arranged above the hoisting winch 1, and the hoisting winch 1 and the luffing winch 2 and the luffing fixed pulley block 4 are arranged on the same frame 3. Both sides of the frame 3 are provided with an ear-shaped support plate 5, the ear-shaped support plate 5 is arranged on both sides of the hoisting winch 1 and the luffing winch 2 drum 7, and the ear-shaped support plate 5 is provided with a number of reinforcing ribs 10. The edge of the ear-shaped support plate 5 is provided with an outward folding structure, and the ear-shaped support plates 5 on both sides are connected by the bottom plate 6 and the connecting plate 11.

[0017] The hoisting winch 1 and the luffing winch 2 are installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com